Packaging machinery uses cutting-edge automation, and it’s no wonder. Facilities that parcel products need to deliver high throughput, but modern consumers demand smart packaging in the form of no-fuss containers that protect everything from M&Ms to patio furniture. What’s more, there’s a continuous drive to customize packages and let consumer-facing companies wrap products for bulk…

Tech Toolbox: Machine design for food automation

Motion system designs run millions of automated food-manufacturing designs worldwide — including those in employed in grain milling, pasta making, and baking; fish and poultry processing; beer, wine, and spirit production; slaughtering and meatpacking; fruit, vegetable, and baby-food packaging, canning, jarring, and freezing; candy making; dairy and cheese making; and oils and fat extraction and…

Stainless steel: The gold standard for equipment cleanliness

The value of safety — both for protecting people from physical harm as well as end users and OEM machine builders from lawsuits — has spurred increased adoption of integrated safety into slicing, baking, and bottling machines especially. Of course, economic pressures must be weighed against sophisticated safety fixtures. Save for a temporary rollback of…

Pneumatics in food manufacture

Pneumatic actuation is ubiquitous in food and beverage-processing equipment because it outperforms electric automation for many tasks. Pneumatics have a lower upfront cost and higher resistance to harsh cleaning — both dry and wet. With minimal electrical or electronic subcomponents at pneumatic axes’ end effectors and points of application interactions, these delicate elements aren’t potential…

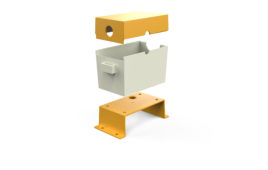

Considering enclosures to satisfy food-safety regulations

The Food Safety Modernization Act (FSMA) imposes world-class regulations using hazard analysis and third-party certifications to ensure food safety. What’s more, a CDC, FDA, and USDA Interagency Food Safety Analytics Collaboration is currently underway to more precisely pinpoint foodborne-illness origins (including those involving automated machinery) using modern approaches. Expansion of the FDA could boost the…

Where machine design intersects with FSMA rules

Remember that while U.S. food-regulatory agencies don’t directly regulate food equipment, they regulate its use to require cleanliness. As part of FSMA, the Preventive Controls for Human Foods Rule demands that all plants registered with the FDA prepare and implement written food-safety plans — or FSPs for short. These FSPs must identify and outline solutions…

Sanitation and safety for food and beverage equipment

Food and beverage equipment must be safe and sanitary. In fact, food safety in particular is a key factor that will drive ROI for food and beverage manufacturers in coming years. Consider some specific examples: End users of grain milling, pasta making, and baking equipment have increasingly prioritized equipment that is quieter than past iterations…

Introducing the mid-range piFLOWfc vacuum conveyor

Chocolates, cookies, chips and coffee but also certain chemicals — the piFLOWfc vacuum conveyor handles all. Suitable for vacuum conveying of food, but also chemicals that do not require the use of full acid resistant stainless steel, Piab’s new piFLOWfc is a premium heavy-duty vacuum conveyor. Using the same design as the company’s premium range piFLOWp…

Self-cleaning filter streamlines sausage production application

Chances are the pork sausage on your breakfast plate came from the grocery store frozen. And if it’s one of the big-name brands, chances are equally good that it was not processed by the company whose name is on the package but by a “co-packer” — a company that specializes in that particular product. One…

Talking manufacturing and education with Festo Didactic’s Thomas Lichtenberger

In our latest Executive Edition series, Mary Gannon of Design World chats with Festo Didactic’s CEO Thomas Lichtenberger, about the organizations successful programs to change the manufacturing landscape in the United States. Festo Didactic provides equipment and solutions for technical education for all areas of technology in factory and process automation, such as pneumatics, hydraulics,…

Dorner’s FlexMove conveyor platform represents a merger between two existing product lines

Dorner has consolidated two existing product lines and unified them into a single platform, which is now called FlexMove. While the FlexMove name isn’t new to Dorner, it now incorporates the features and strengths of the former SmartFlex conveyor line. The FlexMove flexible chain conveyor brings the best engineering and performance standards in flexible conveying…

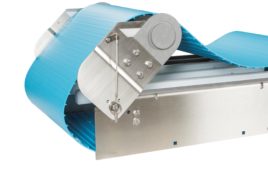

Power four curves on a single motor for Sanitary Platform: AquaGard 7350 V2 conveyor

Dorner’s AquaGard 7350 V2 Curve Conveyor chain features a center bearing to eliminate friction, carry a heavier load and allow four curves to be driven by a single motor. This unique design improves productivity, along with saving valuable floor space as the conveyor can make tight turns around existing machinery and equipment without being hindered…

Hygienic machine components for sanitation, safety and cleanability

Sanitation, maximum cleanability and high-quality materials are design features of the new Hygienic Design line from Elesa. The line includes knobs, lobe knobs, bridge handles and leveling feet designed and manufactured according to the EHEDG (European Hygienic Engineering & Design Group) and 3-A Sanitary Standards guidelines to meet the requirements of specific applications in markets…

Build your own AquaGard 7350 V2 Series sanitary conveyor online

Two models from Dorner’s newly redesigned AquaGard 7350 V2 Series are now available in D-Tools, Dorner’s online conveyor configurator. The AquaGard 7350 V2’s Positive Drive and LPZ (Flat and Cleated belt) models on D-Tools give project engineers, plant managers and others the ability to easily design an AquaGard conveyor to fit their exact application in…

Emerson Rosemount compact hygienic transmitters suitable for food and beverage industry

Emerson today unveiled a new line of transmitters designed specifically for hygienic applications in the food and beverage industry — with a compact form factor that will enable manufacturers to minimize downtime and lower production costs. The new line of transmitters — Rosemount 326P Pressure, Rosemount 326T Temperature, Rosemount 327T Temperature and Rosemount 326L Level instruments…

Emerson’s Rosemount CT4215 uses laser technology to detect leaks and reject defective packages

In response to industry demand for increased quality in food and beverages at every level, Emerson has introduced the Rosemount CT4215 Food and Beverage Leak Detection system. The Rosemount CT4215 is the first quantum cascade laser/tunable diode laser (QCL/TDL) continuous, inline detection system designed to help assure quality and safety, maximize production volume and decrease…

Rexroth’s North American GoTo Focused Delivery Program — 9th consecutive year of growth

For the 9th consecutive year, Bosch Rexroth’s GoTo Focused Delivery Program continues to offer high demand products across Rexroth’s broad range of technologies for fast delivery. More than 99% of the products in the program ship in 10 days or fewer, with the same lead times in the U.S., Canada and Mexico. With the GoTo…

Small-batch ‘malthouse’ product enables home and craft brewers to produce their own malts

The craft beer scene is exploding across the U.S., but the popularity of home- and micro-brewing has uncovered a gap in the supply chain when it comes to malting. To date, malt—a critical ingredient in beer—has been dominated by large industrial malting operations. While it’s easy to get standard bulk malts, brewers looking for local…

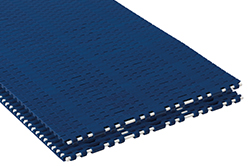

Rexnord announces the Dry-PT Option for select MatTop & TableTop Chains

Rexnord is proud to announce the latest addition to our premium line of conveying solutions products; the Dry-PT material option is now available in North America for select MatTop and TableTop chains. Dry-PT is optimized for applications where sustainability is critical, designed to maintain a constant low level of friction between the conveying chain and…

Rexnord launches 390 Series Chain for beverage industry

Designed to optimize tight transfers in the beverage, food, metal container manufacturing, and pharmaceutical industries, Rexnord launches the Rexnord 390 Series MatTop Chain. The 395 MatTop plastic modular chain features a flat top execution while: –Reducing product damage & loss — with an 8 mm pitch, the chain can go around a nose bar diameter…

Distributed Modular I/O in the food processing and beverage industry for hygienic pressure wash-down applications

Balluff is pleased to introduce industry’s first machine mount, IP69K protection rated, ECOLAB certified distributed I/O modules powered by EtherNet/IP, PROFINET, and IO-Link. End users and machine builders of automation in food, meat, dairy and beverage industries that need to follow stringent food safety requirements can now utilize full benefits of distributed modular I/O architecture…

Sensor handles harsh environments

The TopworxTM GO Switch Model 52M is a 12 mm proximity sensor for applications in outdoor, and challenging industrial environments. The new sensor is well suited for material handling, mobile equipment, industrial equipment, and food and beverage processing applications. The GO Switch 52M is durable and does not require power. It operates across a wide…

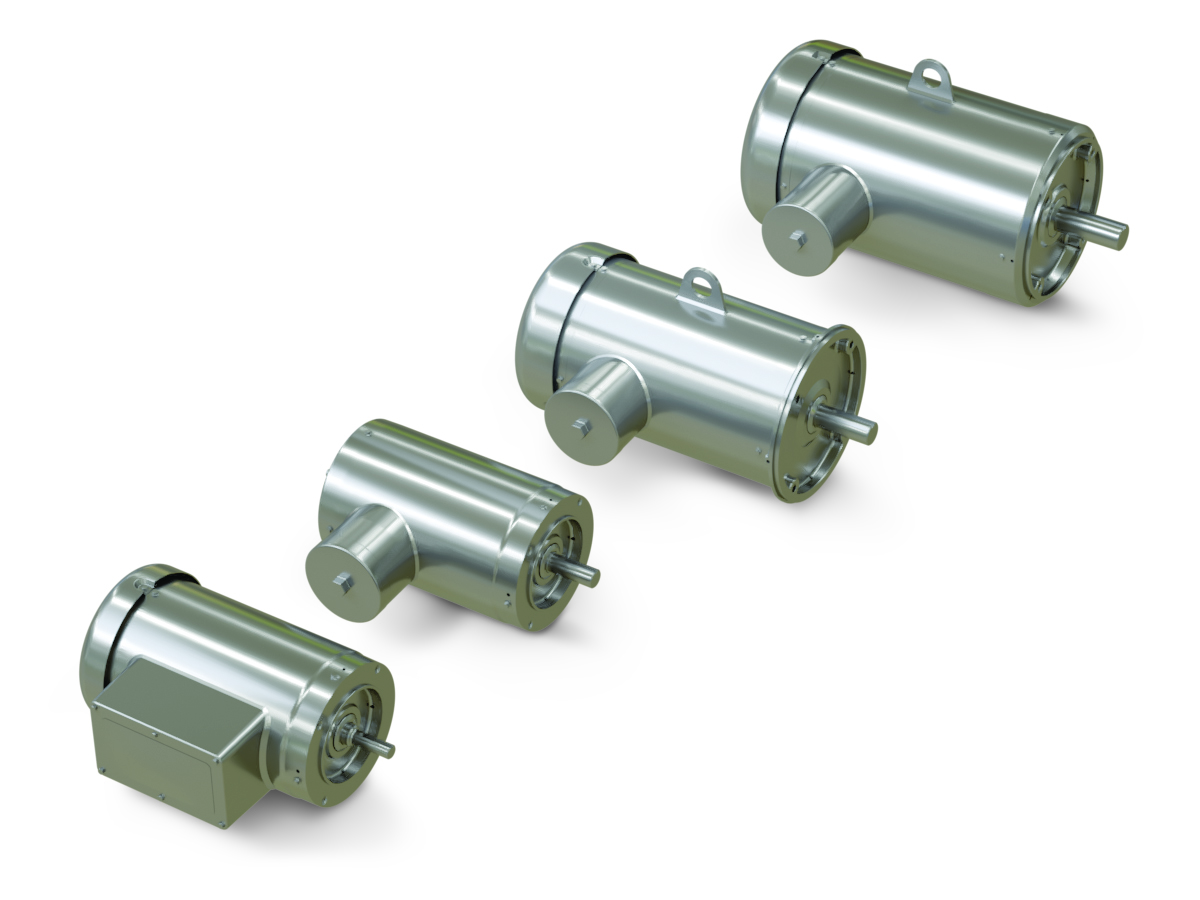

Smooth and safe motors

These stainless steel motors meet the extreme environment needs of the food and beverage industry. Food Safe motors have smooth contours and sealing that exceeds IP69K for water to maximize motor life in high pressure, sanitary cleaning environments. The high ingress protection rated enclosures offer fully encapsulated windings, sealing the motor inside and out. Combined…

Laird’s Thermoelectric Cooling Solutions Offer Cost-effective Alternative for Beverage Cooling

Laird has a long history of providing standard and custom thermoelectric cooling systems to the food and beverage industry. Beverage cooling applications, from soda fountains to coffee machines to wine coolers, require efficient performance, low operating noise, and low maintenance — all in a smaller size. Laird provides compact, solid-state thermoelectric cooling solutions that meet the…

Can smart technology combat the food crisis?

British scholar Thomas Robert Malthus once predicted that the world’s population would outgrow the rate of food production. While things have changed in the two centuries since, population projections indicate that we remain set for a global food crisis. But technology could offset the crisis. Thomas Malthus’ theory, which has since come to be known…