Dorner and its partner company montratec are set to unveil its latest innovations in assembly technology in booth 1224 at Automate 2024, May 6-9, at McCormick Place in Chicago. With a focus on enhancing efficiency and reliability in production environments, both Dorner and montratec will present a lineup of demo conveyors designed to meet the…

Dorner and Garvey combine their strengths on new AquaGard GT Stainless Steel conveyor

Dorner and Garvey are well-established brands with decades of proven success. But now, they are combining their strengths to write a new chapter together with the recent launch of its AquaGard GT Stainless Steel conveyor. This new line combines the best conveyance expertise of both brands to develop a platform with an attractive price point…

Dorner to showcase material handling innovations at Pack Expo East 2024

Dorner will unveil its latest innovations in material handling technology at Pack Expo East 2024 in Philadelphia alongside its partner company Garvey. With a focus on enhancing efficiency and reliability in production environments, Dorner and Garvey will demonstrate conveyors designed to meet the diverse needs of a variety of industries. Dorner’s ERT150, an industry-ready solution…

New DualMove pallet system conveyor from Dorner

Dorner, a pioneer in conveyor technology, is proud to introduce DualMove. This product excels in many applications, including – but not limited to – electronics, appliances, automotive, and battery production. Joining Dorner’s collection of innovative pallet systems, the DualMove utilizes twin-strand timing belts to precisely place, orientate, and transfer pallets to workstations for robotic or…

Light conveyor platform bridges fixed systems with flexible AMRs

Autonomous mobile robots (AMRs) can streamline material handling in manufacturing, logistics, warehousing, and more, yet many facilities still primarily rely on conveyor systems. To serve as a flexible bridge between fixed conveyors and production lines, Interroll designed a light conveyor platform (LCP) to facilitate the handling of lightweight goods with AMRs from Mobile Industrial Robots…

NORD DRIVESYSTEMS offers sweet solutions for the bakery industry

The bakery industry includes many complex processes from mixing and kneading large quantities of dough, heating and cooling baked goods, and packaging and labeling the final product. NORD DRIVESYSTEMS supports the industry every step of the way with reliable drive systems engineered for high efficiency and smooth operation. Specialized configurations cater to all requirements of…

Stay flexible safely

By Matthias Bristle, Product Manager Safety Solutions Leuze electronic GmbH + Co. K,G Different material widths, varying material positions, or partially loaded pallets pose special challenges for transfer station access guarding. For this, Leuze relies on the concept of dynamic format adaptation. In this way, productivity and safety can be optimally harmonized. Variation becomes…

The DCMove Belted Conveyor adds precision to material handling applications

A painted steel frame for added durability makes the new DCMove Belted Conveyor suitable for material handling applications, such as e-commerce, logistics, packaging, and palletizing, among others. The DCMove Belted conveyor offers a streamlined approach to conveyance, which is something many material handling applications call for in their equipment. Helping achieve that goal is the…

Gain extra load capacity with Dorner’s new 2700 medium duty conveyor

For applications that need a little extra boost in load capacity, the new 2700 Medium Duty Conveyor from Dorner has the strength to carry heavier products for a variety of industrial automation and packaging applications, including palletizers, multi-lane processing, case and tray handling, and end-of-line packaging. With regards to Dorner’s industrial flat belt conveyor options,…

Custom pneumatic conveyors for unique applications

Exair’s Line Vac Air Operated Conveyors provide an efficient method of converting ordinary pipe, hose or tubes into powerful in-line conveyors. To accommodate the wide variety of unique problems manufacturers face, Exair has the ability to customize and tailor Line Vacs to different specifications. Certain processes may require customizations like unique sizes, shapes and materials…

iDrive2 Mag-Drive Motor saves energy while boosting sanitary attributes

For customers looking to reduce their sanitary conveyor system’s power consumption by as much as 55%, the new iDrive2 permanent magnet motor for Dorner’s AquaPruf conveyor is a great option. Supplied by OneMotion, a packaging automation products OEM and trusted Dorner partner, the permanent magnet motor uses less energy to run at higher speeds because…

New wheels for ergonomic & AGV applications

In their tireless quest to provide customers with the exact product they need when they need it, Hamilton introduces their newest UltraGlide wheel series. It’s Hamilton’s latest modular solution designed to reduce the amount of energy needed to move loads in manual or powered applications. Designed for ergonomic and AGV applications, the new UltraGlide still…

Self-lubricating and wear-resistant: igus bar stock for food, continuous operation and high media resistance

igus, the Germany-based manufacturer of motion plastics, announced it has expanded its wide range of iglide plastic bar stock by no less than four materials; among them two for the food sector: the heat-resistant material iglide AC500 and the resilient material iglide A250. The extremely hard-wearing material iglide H3 and the particularly wear-resistant endurance material…

Dorner’s AquaPruf Ultimate conveyor Platform earns 3-A certification

Dorner’s AquaPruf Ultimate conveyor is now 3-A certified. Evaluating equipment for 3-A certification is performed by an objective, independent third-party verification inspection to ensure that the AquaPruf Ultimate conveyor has successfully met the requirements of the 3-A sanitary standard in the design and fabrication of equipment used in food processing. Recent updates to the platform…

Conveyor certified for cleanroom and small and light-load assembly automation applications

The next evolution in Dorner’s Edge Roller Technology conveyor platform, the ERT150, is for small and light-load assembly automation, as well as medical and medical-device assembly applications. It is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating…

Dorner’s redesigned AquaPruf Conveyor brings users the latest in food safety features

Dorner is never one to rest on its laurels, and that philosophy of constant improvement is shown in its newly redesigned AquaPruf Conveyor, the latest iteration of its popular selling AquaPruf sanitary conveyor platform. Dorner design, application, manufacturing and integration of precision industrial and sanitary conveyor systems. Dorner listens to customers and responds to evolving…

Roller chain conveyor includes dynamic control

Glide-Line announced the release of their completely configurable steel roller chain conveyor system featuring dynamic traction control with a built-in accelerator to assist with faster start-up. A first of its kind, this product allows mixing and matching of traction control in a line, from low back pressure to high traction, with ultimate configurability and flexibility…

Glide-Line roller chain conveyor with dynamic control

Glide-Line announced the release of their completely configurable steel roller chain conveyor system featuring dynamic traction control with a built-in accelerator to assist with faster start-up. A first of its kind, this product allows mixing and matching of traction control in a line, from low back pressure to high traction, with ultimate configurability and flexibility…

Stop and divert pucks and packages

Dorner is now offering a Puck Stop Module and a Puck/Package Divert Module on its FlexMove conveyor system that gives users the ability to stop pucks or packages for pacing requirements, as well as divert pucks and packages into a second lane. The pneumatically-operated Puck Stop Module is available in two models: Vertical Blade Stop,…

Create zones for better control in accumulation and assembly applications

As automation becomes more integrated into medium- and heavy-load accumulation and assembly applications, the need for conveyors with zoning capabilities increases. Dorner’s Edge Roller Technology (ERT250) precision edge roller pallet and tray handling conveyors are engineered specifically to handle zone functionality. Creating zones along a conveyor is an important feature for applications where product accumulates…

Gain more layout flexibility with the new tight turning radius option for Dorner’s FlexMove Helix Conveyors

The new tight turning radius option on Dorner’s FlexMove Helix Conveyors allows for compact turns with a diameter of spiral measuring 1,000 mm (39.4 in.) at centerline. The advantage this new tight turning radius option brings to customers and their facilities is even greater flexibility in layout for applications such as accumulation, buffering, cooling product…

How to amplify your conveyor system with robotics

The integration between conveyors and robotics has brought a much higher level of automation to various packaging applications in recent years. The two components work hand-in-hand to deliver a streamlined, efficient operation with more accuracy and a strong return-on-investment. In 2021 and beyond, this joint effort will only get stronger within industries like packaging as…

Dorner’s FlexMove Helical Plain Bend Conveyors provide unlimited configurations for added flexibility

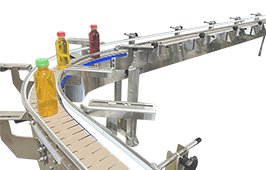

For those applications that require conveyor flexibility, but with a small footprint to save valuable floor space, Dorner’s FlexMove Helical Plain Bend Conveyors offer the solution. FlexMove Helical Plain Bend Conveyors provide customers with unlimited configurations, including flat to flat; flat to incline or incline to flat; or incline to incline. These configurations, which also…

Gain flexibility with the FlexMove Helical Plain Bend conveyors

For those applications that require the ultimate in conveyor flexibility, but with a small footprint to save valuable floor space, Dorner’s FlexMove Helical Plain Bend Conveyors are the solution. FlexMove Helical Plain Bend Conveyors provide customers with unlimited configurations, including flat to flat; flat to incline or incline to flat; or incline to incline. These…

Dorner hosting on-demand webinar on its ERT250 Pallet Conveyor at Automate Forward, March 22-26

Dorner is hosting a webinar on its new Edge Roller Technology (ERT250) Pallet Conveyor during Automate Forward, March 22-26, 2021. Automate Forward is the automation industry’s premier virtual trade show and conference. The on-demand webinar hosted by Mike Hosch, vice president, Industrial Business Unit, Dorner, looks at the performance and functionality of the ERT250, and…