The Fischer Freedom technology platform launched in June 2018 by Fischer Connectors, continues to gain international recognition among the company’s peers throughout the electronics world. Within a single year, the Fischer LP360 connector — the first product of the technology platform — has won two “Best Product of the Year” awards in 2019, and two […]

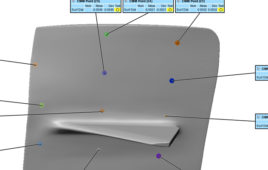

Scanning or CMM? Which is better?

Long-established technology of Coordinate Measuring Machines (CMM) is being challenged in various markets by fast-emerging, highly advanced science of blue light scanning. By Matthew Martin, Exact Metrology For more than 50 years, the benchmark for accuracy in measuring solid objects, whether machined, molded, die cast, welded or forged, was the coordinate measuring machine. Using a […]

Toughened epoxy polysulfide hybrid offers advanced chemical resistance

Master Bond EP21TP-2NV is a two part epoxy polysulfide formulated for use as an adhesive, sealant and potting system. It withstands prolonged exposure to many harsh chemicals including fuels, oils, hydrocarbons, and hydraulic fluids. It is also fully RoHS compliant, meeting RoHS3 Directive (EU) 2015/863. EP21TP-2NV offers an elongation between 40-80% at room temperature and…

University of Sheffield becomes one of the first UK recipients of new additive manufacturing technology by Desktop Metal

Two leading manufacturing centres of excellence in the UK have been named as the first to install additive manufacturing technology developed by Desktop Metal, a company committed to making metal 3D printing accessible to global manufacturers and engineers. World top 100 academic establishment the University of Sheffield, and global engineering solutions firm Weir Group, are […]

New America Makes Satellite Center to be on the campus of Wichita State University

America Makes announced that its third America Makes Satellite Center will be located on the campus of the Institute’s Platinum-level member, Wichita State University (WSU) within the facilities of the National Institute for Aviation Research (NIAR) in Wichita, Kan. The Memorandum of Understanding (MOU) between America Makes, which is managed by the National Center for […]

Tradeshow trio spotlights industrial transformation in China

PTC ASIA, the leading tradeshow in Asia for power transmission and fluid technology, runs again from October 23-26, 2019 in the Shanghai New International Expo Center (SNIEC). The event covers a display area of 100,000 sq-m and features the exhibit categories electrical and mechanical drives, fluid technology, ball bearings, and motors and engines — as…

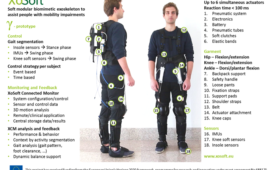

XoSoft exoskeleton gives users quasi-passive actuation

A lot of people have lower limb mobility impairments, but there are few wearable technologies to enable them to walk normally while performing tasks of daily living. XoSoft, a European funded project, has brought together partners from all over Europe to develop a flexible, lightweight and resource-efficient soft exoskeleton prototype. Frail elderly, incomplete spinal cord…

Automated system from MIT generates robotic actuators for novel tasks

When designing actuators involves too many variables for humans to test by hand, this system can step in.

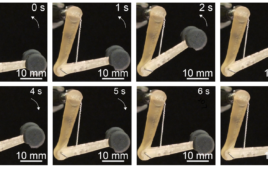

Artificial muscles based on MIT fibers could make robots more responsive

New MIT system of contracting fibers could be a boon for biomedical devices and robotics.

Robert Bosch Venture Capital invests in Xometry

Xometry, an on-demand manufacturing marketplace, announced that Robert Bosch Venture Capital (RBVC) will join the recently announced Series D round. RBVC joins Greenspring Associates, Dell Technologies Capital, BMW i Ventures, Foundry Group, GE Ventures, Highland Capital Partners, Maryland Venture Fund and Almaz Capital as investors in the round. This additional investment brings the total amount […]

Briggs Automotive integrates 3D printing into the development of its new Mono R supercar

Royal DSM announced a collaboration with Briggs Automotive Company (BAC), the British supercar manufacturing company based in Liverpool. The two companies will co-develop innovative 3D printing applications for the new BAC Mono R and showcase the potential of additive manufacturing to reduce weight and increase customization in the automotive industry. Both companies are convinced that […]

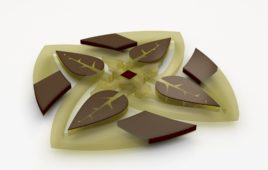

Programmable soft actuators show potential of soft robotics at TU Delft

Researchers at TU Delft have developed soft actuators that could help soft robots collaborate with humans.

What bearings are best for corrosion resistance?

There are several industries where corrosion resistance is important, but not all bearings are suited for use in environments with moisture, acids, gases, and other potentially damaging substances. Corrosion can lead to several problems that range from bearing damage that impacts performance and part lifespan to product contamination. These issues make it important to identify […]

Why use plastic bearings?

While bearings are most commonly made of metal, there are other materials that offer some distinct advantages depending on the needs of an application. Plastic bearings are versatile components that can come in several different forms, including deep groove, thrust, angular contact, and miniature bearings. Manufactured in a range of styles, the use of plastic […]

How to reduce the cost of 3D printing: use hollowing

Several 3D printing and additive technologies, such as the powder bed and stereolithograpy technologies, primarily build solid objects. The benefits of solid objects are that they are usually strong and resistant to breakage. But they are also costly because of the amount of material used to build them. Another potential drawback is that excess material […]

MIT ‘walking motor’ could help robots assemble complex structures

Years ago, MIT Professor Neil Gershenfeld had an audacious thought. Struck by the fact that all the world’s living things are built out of combinations of just 20 amino acids, he wondered: Might it be possible to create a kit of just 20 fundamental parts that could be used to assemble all of the different…

Solar Atmospheres adds all-metal hot zone furnace

Solar Atmospheres recently installed another unique, all-metal hot zone vacuum furnace at its 1969 Clearview Road facility in Souderton, PA. This is Solar’s third all-metal hot zone furnace installation for their climate-controlled room. The additional furnace increases Solar’s capacity for processing sensitive materials such as PH stainless, nickel-chrome based superalloys, titanium, and ferritic and austenitic…

New VAL-U-LOK connectors increase current ratings to 13 A

TE Connectivity has introduced an extension of its VAL-U-LOK connector product line that increases the maximum current rating from 9 to 13 A in the broadly accepted 4.2-mm centerline spacing connector system. TE’s new 13A VAL-U-LOK connectors support high current requirements for wire-to-board and wire-to-wire connections in a wide range of applications where power must […]

Sciaky enters R&D initiative with Aubert & Duval and Airbus

Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI) and provider of metal additive manufacturing (AM) systems, announced it has entered into an ambitious research and development (R&D) initiative with Aubert & Duval and Airbus, driven by the Saint Exupéry Institute for Research in Technology (IRT). The Production Engineering laboratory of the National School […]

R+W stainless steel mesh inserts help in high-temp environments

Precision elastomer insert couplings offer technical advantages in a wide variety of power transmission applications. With the rigid jaw hubs machined from solid round bar stock, the torque density can be superior to that of almost any other type of backlash free flexible coupling, depending on the stiffness of the elastomer insert which is used. […]

Full-color 3D printing poised to change the game for businesses everywhere

While full-color 3D printing has been around for many years, it is now gaining meaningful traction. In part this is because next-generation technologies are entering the market, offering capabilities that improve quality and performance, while at the same time helping to reduce cost. Soon affordable, high-quality color 3D printing will benefit organizations in many different…

‘Self-Healing’ Polymer Brings Perovskite Solar Tech Closer to Market

A protective layer of epoxy resin helps prevent the leakage of pollutants from perovskite solar cells (PSCs), report scientists from the Okinawa Institute of Science and Technology Graduate University (OIST). Adding a “self-healing” polymer to the top of a PSC can radically reduce how much lead it discharges into the environment. This gives a strong…

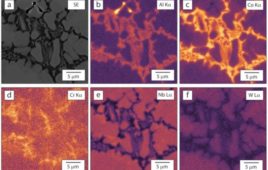

Materials Informatics Reveals New Class of Super-Hard Alloys

A new method of discovering materials using data analytics and electron microscopy has found a new class of extremely hard alloys. Such materials could potentially withstand severe impact from projectiles, thereby providing better protection of soldiers in combat. Researchers from Lehigh University describe the method and findings in an article, “Materials Informatics For the Screening…

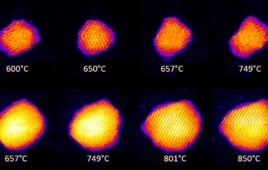

Phase-Change Materials from Smartphones May Lead to Higher Data Storage, Energy Efficiency

Phase-change materials that are used in the latest generation of smartphones could lead to higher storage capability and more energy efficiency. Data is recorded by switching between glassy and crystalline material states by applying a heat pulse. However, to date it has not been possible to study what happens at the atomic level during this…

Research Reveals Liquid Gold on the Nanoscale

The research published in Nature Communications set out to answer a simple question – how do nanoparticles melt? Although this question has been a focus of researchers for the past century, it still is an open problem – initial theoretical models describing melting date from around 100 years, and even the most relevant models being some 50…