Hot runners have been a common manufacturing tool in the plastic injection molding industry for more than 30 years. With this technology came improved efficiencies and benefits. Although hot runners for zinc die casting have surfaced from time to time, die casting with molten metal proved to be much more challenging for this technology compared…

Desktop Metal launches H13 tool steel for hot and cold work tooling applications

Desktop Metal announced the launch of H13 tool steel for the Studio System, the office-friendly metal 3D printing system for prototyping and low volume production. Characterized by its stability in heat treatment, exceptional hot hardness, and abrasion resistance, H13 is a tool steel widely used in hot work applications. High toughness and hardness also make […]

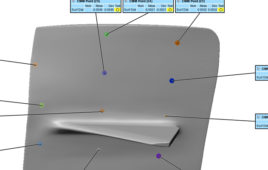

Scanning or CMM? Which is better?

Long-established technology of Coordinate Measuring Machines (CMM) is being challenged in various markets by fast-emerging, highly advanced science of blue light scanning. By Matthew Martin, Exact Metrology For more than 50 years, the benchmark for accuracy in measuring solid objects, whether machined, molded, die cast, welded or forged, was the coordinate measuring machine. Using a […]

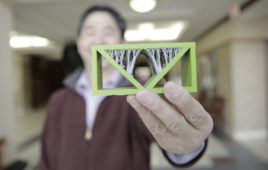

Advancing Additive Manufacturing by Slashing Support

3D printing opens up design possibilities that engineers could once only dream of. The technology allows manufacturers to create parts with unique and complex shapes—parts that conventional manufacturing methods such as die casting or injection molding can’t produce. With 3D printing, also known as additive manufacturing, a machine creates a part by adding material in…

What’s new in additive manufacturing for part production?

If you plan on attending IMTS this year, be sure to check the additive manufacturing for part production systems that will be on display. A number of additive manufacturing vendors will be there, so it’s a good opportunity to check out the systems and ask questions of the vendors. One of the companies that will […]

New additive manufacturing technique uses Mach 3 speeds to build parts

An innovative and new additive manufacturing approach was shown at the recent RAPID + TCT show in Ft. Worth, TX. This new additive manufacturing technology uses supersonic deposition. Material is shot through a jet engine nozzle at speeds to Mach 3, and deposited in geometric patterns layer by layer. SPEE3D introduced this technology, referred to […]

Stereolithography Answers Challenge Of 3D Manufacturing

The landscape of additive manufacturing has changed dramatically since the commercialization of stereolithography (SL) as the first viable 3D printing technology. In fact, the terms “3D printing” and “additive manufacturing” (AM) only entered the popular vernacular in recent years. The scope of additive manufacturing has changed dramatically. Technologies encompassing thermoset and thermoplastic materials, along with…

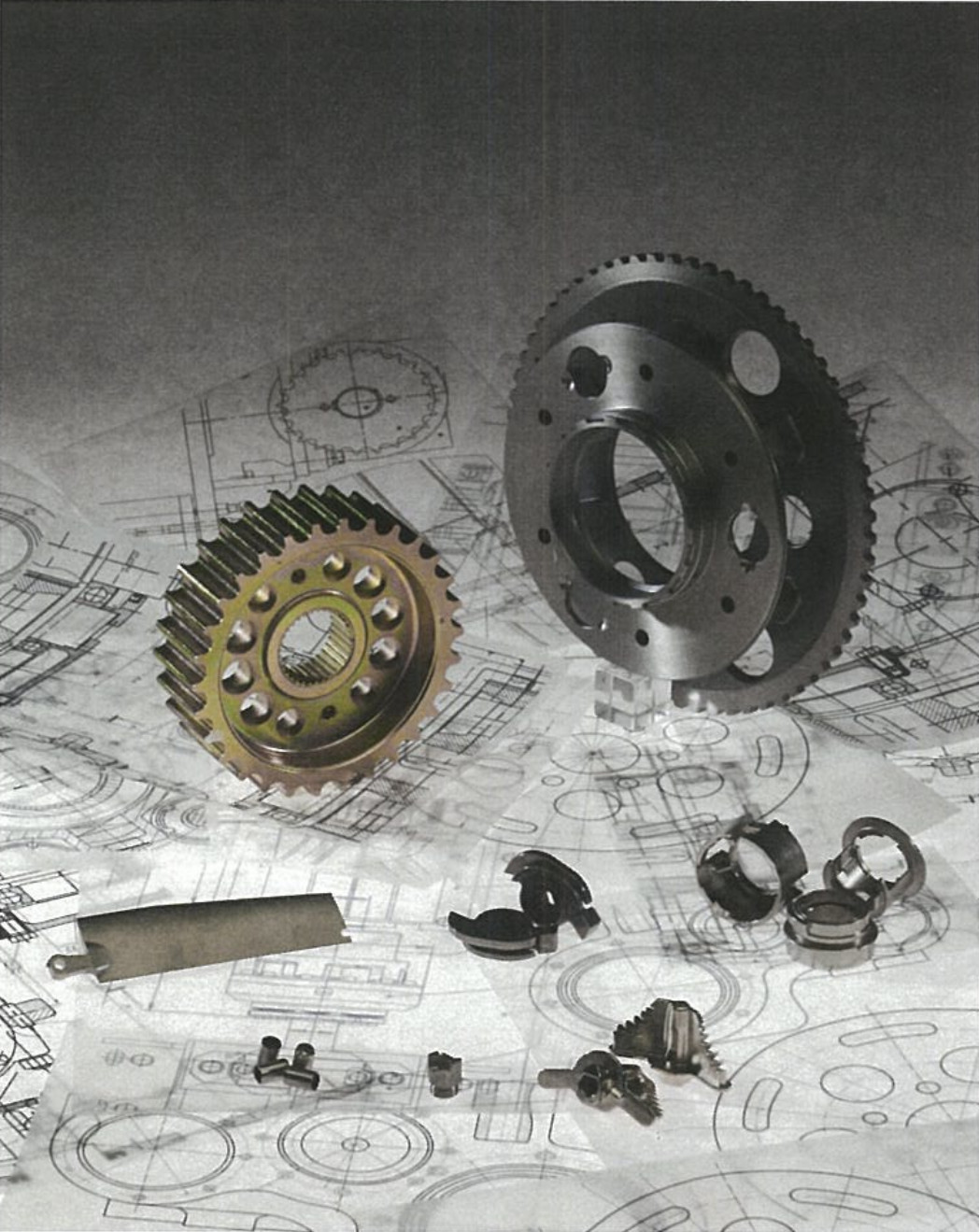

Award-Winning Powder Metal Parts

The winners in the 2017 Powder Metallurgy (PM) Design Excellence Awards competition, sponsored by the Metal Powder Industries Federation (MPIF), demonstrate outstanding examples of PM’s diversity. These component fabricators use PM’s flexibility to push forward new concepts and process controls and demonstrate the inexhaustible well of capabilities PM can marshal in the service of component…

Working with metal materials for additive manufacturing

Perhaps more than any other manufacturing process, additive manufacturing works best when you match the material to the right additive process. Some of the challenges, though, are: –many additive processes suggest proprietary versions of materials — plus these materials often do not have sufficiently available documentation on their performance after undergoing an additive process –the […]

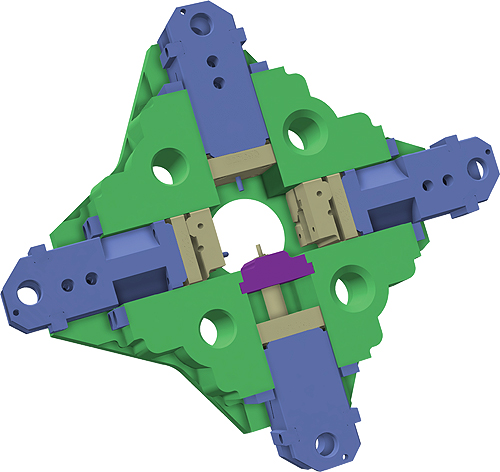

Five Steps to Optimize Casting and Eliminate Defects – Transcript

This is the unedited transcript for webinar: Five Steps to Optimize Casting and Eliminate Defects. Click here to watch the webinar on demand. Lesley: Hello everyone and thank…

4 Reasons to Turn to DMLS Before Die Casting

Die cast aluminum is a staple in the production of metal transportation products, from motorcycle brakes to steering gear housings to transmission casings. Die casting turns out hundreds to thousands of well-finished parts a day which require very little post-processing – critical for huge production volumes. However creating the tooling for die cast parts requires…

Proto Labs Launches Rapid Magnesium Injection Molding Service

Proto Labs has introduced magnesium injection molding into its current rapid manufacturing services. This advanced injection molding process enables product designers and engineers to prototype using the same materials and processes used for the final part production. In addition to prototypes, Proto Labs will offer production parts in quantities of up to 5,000+ with a…

Proto Labs launches rapid magnesium injection molding service

Proto Labs, Inc. has introduced magnesium injection molding into its current rapid manufacturing services. This advanced injection molding process enables product designers and engineers to prototype using the same materials and processes used for the final part production. In addition to prototypes, Proto Labs will offer production parts in quantities of up to 5,000+ with…

Making Metal Injection Molding Faster

by Tim Sparkman, Metal Injection Molding (MIM), Operations Manager, Dynacast Metal injection molding can be made faster. Part of the process involves speeding the production of pre-sintered parts. Metal Injection Molding (MIM) has proven its worth as a reliable way to make precision parts at high production volumes. MIM also offers plenty of design flexibility…

Intellectual property rights and 3D printing—much ado about nothing?

3D printing and intellectual property protection or rights is back in the news again, thanks to Nathan Myhrvold, former Microsoft CTO and now owner of Intellectual Ventures, a company that “believes that ideas are valuable” and therefore works at developing patents. The latest patent, Manufacturing Control System, has many in the 3D printing community debating […]

Instead of machining, consider metal injection molding

Metal injection molding (MIM) is an effective way to produce complex and precision-shaped parts from a variety of materials. It offers several advantages over die casting, investment casting, and machining in such applications as firearms components, medical jaws, turbochargers, and micro sized components. Component size can range from 0.0001 in.3 to 2.5 in.3. In a…

Tips for Selecting Aluminum Extrusions & Accessories

This webinar will focuses on the selection of Aluminum Extrusions and Accessories relating to the user’s specific application requirements. Typical applications for aluminum extrusions include: safety guarding, enclosure, work station, light machine base, shutter, robotic jig and fixture, material handling, display exhibits, as well as many others that can be utilized in a variety of industries…

Material Matters: Aluminum

Aluminum is one of the most useful and widely used industrial metals. It is light and resistant to corrosion. It is relatively soft, ductile, and malleable and can be formed by machining, casting, drawing, extrusion, or stamping. And it can be alloyed in many ways to produce a wide range of characteristics. Firstcut machines […]

Die Cast Prototyping The Right Way

By Adam Scichitano, Engineering Manager, Dynacast, Lake Forest, CA and Mike Guilfoyle, General Manager, Dynacast Tooling Division, Germantown, WI Reprint info >> What’s the best way to rapid prototype a die cast component? Engineers with some die casting experience may reflexively answer “spin casting” or “machining.” A better answer, however, would be “die casting.” Prototypes…

Thermoplastics: A Solid Choice for 3D Printing

When designing a new product, engineers can best predict its end performance by prototyping with a material as similar to it as possible. Fused Deposition Modeling (FDM) thermoplastics use the same types of raw materials found in injection molding – and that’s why 3D printing is a wise choice. You’ll learn the unique properties of…

Investment Casting… Making the Unmakable Part

By Jim McGeeney, Director, FS Precision Tech, Rancho Dominguez, CA Reprint Info >> The latest investment casting is a successful marriage of ancient and modern technology. Because it was invented 4000 years ago, you might expect investment casting to be a thoroughly mature metal-forming process. However, investment casting is adaptable, readily lending itself to such…

Zinc Die-Cast Stop Locks From J.W. Winco

J.W. Winco, Inc. announced it now offers series GN 702 Zinc Die-Cast Stop Locks with four indexing positions. These metric sized, RoHS-compliant stop locks offer a fast and easy way to close and hold doors, flaps, slide-in models, etc. by locking in four 90° positions. Three versions are offered: with flange for surface mounting,…

Injection Molding with Magnesium

Once known as an arduous and sometimes unpredictable process, magnesium injection molding is now an established technology. When the magnesium element is combined with small percentages of aluminum and zinc (AZ91D), and aluminum and manganese (AM60B), the alloy can be used to produce durable, lightweight parts. Products made with magnesium are also environmentally friendly, 100%…

Building a Better Deck

Take a look beneath the floorboards of the prefabricated residential deck system from SigmaDek Ltd. There is no wood. With an aerospace inspired design, SigmaDek has replaced lumber with an aluminum substructure of die cast and extruded components to reduce lifetime maintenance, simplify fabrication, and increase safety. Extrusions form the ledger board, beams, joists, and…

Eliminate Parts and Lower Assembly Costs

Robinson Rubber Products, a designer, developer and manufacturer of custom-molded rubber products, extruded rubber products and precision rollers, has several new capabilities to bond molded rubber components to your parts to deliver superior performance. Bonding rubber to your part can also eliminate secondary operations and extra components, plus reduce weight and costs. Using up to…