HELPING ENGINEERS MEET SPECIFIC REQUIREMENTS

EP3HTS-TC: Highly Thermally Conductive, NASA Low Outgassing Epoxy

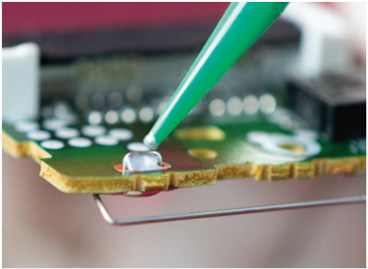

EP3HTS-TC is a one part epoxy well suited for automatic dispensing equipment or manual syringes and can be applied without any tailing. It is primarily formulated for use as a die attach and special purpose bonding material. It utilizes a non-sintering silver technology to provide ultra-high heat transfer capability.

Supreme 70CN: Toughened Epoxy Derived from Sustainable Ingredients

Supreme 70CN is a two part epoxy adhesive formulated using a natural, renewable and sustainable ingredient. This moderate viscosity unfilled epoxy is black in color and can be utilized for bonding, sealing, coating and potting. It passes NASA low outgassing specifications, has a high glass transition temperature, and a high tensile strength.

Resource Library

Keep informed of the latest developments in adhesive technology. Get the answers you need from top industry experts.

White Papers

Master bond offers an easy to read collection of white papers that provide concise answers and solutions to difficult issues.

Case Studies

Case studies provide specific examples of Master Bond adhesives used by research institutions, universities, and national laboratories.

Videos

Enjoy friendly characters and helpful hints in brief videos that focus on product highlights and how to demonstrations.

Master Bond formulates cutting edge adhesives, sealants, coatings and potting/encapsulation systems utilizing advanced technology for challenging applications.

High Performance Adhesives, Sealants & Coatings

Our expansive line of epoxies, silicones, UV curable and LED curable compounds can be customized to meet a myriad of property requirements including:

• High/low temperature resistance

• Electrical conductivity/insulation

• Thermal conductivity

• High/low viscosity

• Flexibility and toughness

• Chemical resistance

• Optical clarity

Developed to withstand harsh environmental conditions, our products feature superior long-term durability. They are used in a variety of industries and are designed to meet stringent industry standards and are certified for:

• NASA low outgassing

• USP Class VI

• FDA CFR 175.300 & FDA CFR 175.105

• UL 94V-0 & UL 94V-1

• ISO 10993-5

and more

Outstanding Customer Support

Master Bond makes customer support a fundamental priority in the adhesive selection process. Our technical specialists have decades of experience and will work with you, one-on-one, throughout the design, prototyping and manufacturing stages of your application.