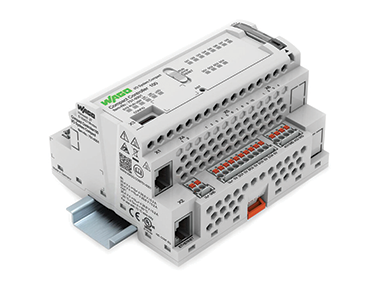

PLC and Remote I/O All in One

The Compact Controller 100 is a small-scale PLC with a wide variety of remote I/O for use in smaller applications. Engineered for OEMs, IIOT digitization projects, and building automation applications, this easy to use device is cost effective for small, but demanding applications. The CC100 uses the latest Codesys 3.5 programming software to utilize the controller’s built-in Web Server to develop HTML 5 visualizations.

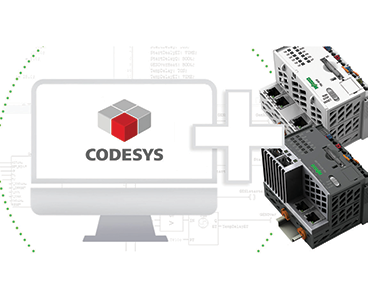

New Programming Option for WAGO PFC200 Controllers

WAGO is integrating the manufacturer-independent automation software, Codesys 3.5, as a programming option in a set of select PFC200 controllers. This software will help develop control code and visualizations for both simple and complex applications. Codesys 3.5 will allow users access to popular fi eldbuses including EtherCat Master, ModBus TCP Master and Server as well at Ethernet/IP Master and Adapter. Built-in security options include role-based permissions and file encryption.

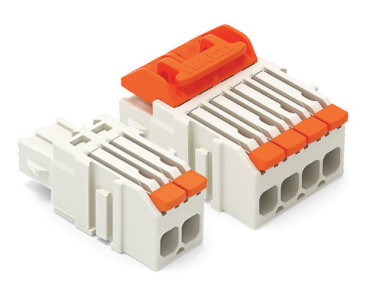

The LEVER-Lution Continues

The levers on the 2734 Series MULTI CONNECTION SYSTEM MINI (MCS MINI) provide rapid, reliable connections in the field. In addition to the intuitive lever operation, these connectors come with a versatile locking system, providing an extra layer of safety and protection against mismating. Another benefit is that extra board space is not required, giving this system the edge for device connections such as drive controls.

WAGO Corporation provides North America with innovative Interconnect, Electronic Interface, and Automation solutions. Headquartered in Germantown, WI, WAGO features state-of-the art manufacturing and 75,000 square feet of storage capacity for 37,000 product locations. Extensive engineering resources, a 25,000+ product portfolio, custom manufacturing, and a global network of dedicated professionals ensure WAGO has the resources and expertise to help you get the job done. To see our capabilities in action, watch the video at www.wago.us/capabilities.