Tunnels are getting larger, deeper, and excavated in more challenging conditions. There is also growing pressure to successfully complete these projects while meeting increasing demands for performance, on-schedule delivery, and safety. However, on many projects, concrete tunnel segments are fitted with rubber gaskets onsite and secured using adhesive, which can lead to time-consuming and cost-intensive repair work as a result of displacement between segments that are not accurately positioned. This can reduce the gasket’s ability to withstand water pressure, exerting negative effects on the outcome of a project.

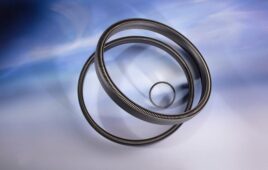

Cast-in profile sealing systems help the tunneling industry keep to project timescales and budgets, and shorten the production process of concrete tunnel gaskets.

The sealing system is pre-cast into the tunnel segment during manufacture, removing the need for adhesive on installation, which enables installers to save time and money. The gasket forges a superior bond connection with the segment to improve installation accuracy and ensure increased water tight performance.

Trelleborg

trelleborg.com

Filed Under: Seals • O rings, Off highway • construction • agriculture, Seals

Tell Us What You Think!