While some companies are promising an entire car made of 3D-printed parts, C.ideas, a rapid prototyping company, is using 3D scanning and printing technologies to create and manufacture replacement parts for rare vehicles.

While some companies are promising an entire car made of 3D-printed parts, C.ideas, a rapid prototyping company, is using 3D scanning and printing technologies to create and manufacture replacement parts for rare vehicles.

The company used scanning, software and printing products from 3D Systems to produce more than 40 replacement components for a Lotus 340R, a concept car of which only 340 were made in 1998.

“A lot was being written about projects to build an entire 3D-printed car,” said Mike Littrell, founder and president of C.ideas. “But 3D printing an entire car is not a viable solution at this time and is not likely to be for decades. I think the market for replacement components and custom-made items for rare vehicles is an immediate opportunity.”

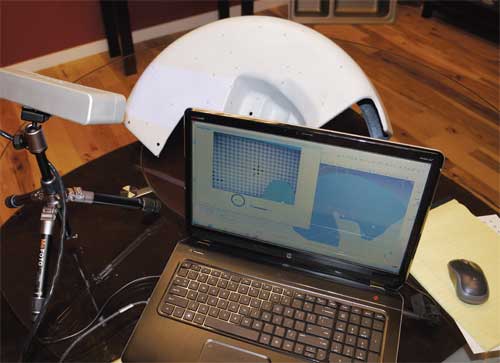

The company used Geomagic Capture from 3D Systems to capture and process the complex curves and intricate design points of the car. Geomagic Capture brings together a compact, ultra-precise, blue-light LED scanner and software that enables designers to quickly build a 3D model from multiple scans and import it directly into specific CAD applications.

When the Geomagic Capture system arrived, work began immediately. The first scans were of the Lotus’ front hood panel, requiring about 15 to 20 scans to capture.

The finished car contained more than 40 3D-printed parts, including the hood, fenders and the rear wing of the car.

The finished assemblies created by C.ideas included the front hood, rear deck-lid, fenders and rear wing of the car. The deck-lid was modified after surface capture to include a cold air intake and vents. The wing was expanded to create greater drag at higher speeds. Original fiberglass parts, such as the front hood, were replaced with ABS parts that provide greater flexibility and resistance to cracking. Scans for the trunk were exported to PTC Creo software and sent out for additional design work.

Final models were printed in the materials best suited to meet design, performance and maintenance needs. 3D Systems iPro 8000 systems were used for all the stereolithography parts and the 3D Systems sPro60 HD/HS for the selective laser sintered parts.

Modeling software allowed designers to add a cold air intake and vents to the original design.

The fenders presented one of the greatest challenges. In the Lotus 340R, they’re free-floating above the wheels, protruding outside the body of the car in a motorcycle-style design, with tight-fitting cutaways to accommodate brake lines, springs and other components.

The dark-colored fenders were spray-painted in white rubber latex to facilitate scanning, after which the rubber was peeled off. Within three or four days, the fenders were recreated, 3D printed in ABS material and mounted.

The Lotus 340R’s washer fluid reservoir and a custom steering-wheel insert were also scanned, modeled and printed. This time, Geomagic Design X software, known for its ability to produce history-based 3D CAD models directly from scans, was incorporated into the process.

Geomagic Capture, a 3D scanner with integrated processing software, allowed C.ideas to quickly capture part geometry to accelerate modeling and 3D printing.

Geomagic Design X allows users to extract splines directly from the scan data. The software is able to generate feature-based, editable solid models from 3D scans for direct import into SolidWorks, PTC Creo and other CAD packages.

Both the washer-fluid reservoir and the steering wheel insert were printed on a 3D Systems Projet sPro 60 using the lighter, more durable Duraform GF material. The fenders, initially printed in ABS, were also reprinted in Duraform GF.

C.ideas

www.prototype3d.com

3Dsystems

www.3dsystems.com

Filed Under: Software • 3D CAD, Automotive, ENGINEERING SOFTWARE, MOTION CONTROL, MORE INDUSTRIES

Tell Us What You Think!