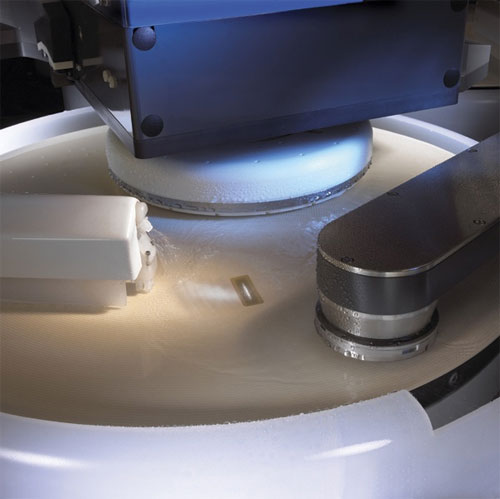

Applied Materials, Inc. today announced its new Applied FullVision™ system that enables real-time control of dielectric CMP1 processes to the 45 nanometer (nm) device node and beyond. The FullVision system couples Applied’s patented window-in-pad technology with multiple-wavelength spectroscopy to deliver advanced in situ endpoint capability for a variety of dielectric materials, including oxide, STI2, and poly CMP applications. The system demonstrates high repeatability across all applications with less than 150 angstrom, 3-sigma endpoint accuracy on patterned wafers. A major advance over single wavelength endpoint technologies, the FullVision system offers improved measurement accuracy with 50% higher reliability for dielectric applications.

“CMP endpoint technology was pioneered by Applied Materials and is key to delivering benchmark CMP performance,” said Dr. Hichem M’Saad, vice president and general manager of Applied Materials’ Dielectric Systems and CMP Business Group. “As films become thinner, CMP becomes increasingly difficult, requiring much more precise wafer-to-wafer process control to achieve acceptable yields. Using broadband spectral analysis, FullVision technology monitors individual polishing zones across the wafer to provide twice the accuracy and repeatability of competitive systems on a wide variety of process steps — without compromising throughput. These are vital requirements for advanced device manufacturing.”

The FullVision system has already been adopted by major memory customers on their Applied Reflexion® LK CMP systems in high volume manufacturing. For these customers, the system has enabled higher CMP yield by significantly reducing wafer scrap caused by drifts in consumable sets and incoming wafer profile variations.

The Applied FullVision CMP endpoint system is a major advancement over single wavelength endpoint technologies, offering twice the measurement accuracy with 50% higher reliability for dielectric applications, including oxide, STI and poly CMP.

Applied Materials leads the industry in CMP technology – with an installed base of more than 900 300mm CMP systems worldwide – and in providing advanced in situ metrology for ensuring best-of-breed planarization performance. See http://appliedmaterials.com/products/reflexion_lk_cmp_4.html for more information on the Applied FullVision endpoint system.

1 CMP=chemical mechanical planarization

2 STI=shallow trench isolation

Filed Under: Semiconductor manufacture, Materials • advanced

Tell Us What You Think!