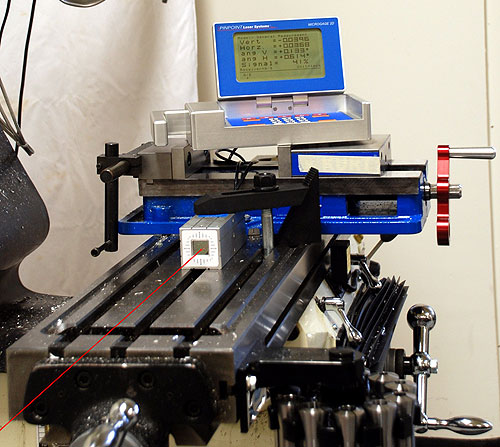

Pinpoint Laser Systems® announces a new four axis Microgage Receiver that provides useful alignment information for evaluating and correcting machinery alignment problems. The new 4D Microgage Receiver measures two linear axes X and Y and their two angular components yaw and pitch. The two linear axes show how well machinery is aligned along a common centerline and the angular readouts show if parallelism problems are present. The new 4D Microgage Receiver is ideal for aligning lathes, turning centers, spindles as well as moving linear slides, rams and pistons, injection molding machinery, moving mechanical sub-assemblies and more. A compact, digital display provides precise linear and angular readings and is easy and intuitive to use.

The method of operation is simple – a narrow laser beam provides a measuring reference line and the 4D Microgage Receiver measures where this laser line lands on an internal detector and determines the position of a machine or sub-assembly relative to this laser reference beam. This receiver will operate over distances of 100 feet or more and deliver a measuring precision of 0.0005 inch and 0.005 degrees; ideal for demanding industrial alignment applications. The Laser Microgage system along with this new 4D Microgage Receiver puts precise measuring and alignment capability right into the hands of plant engineers and manufacturing personnel so that they can monitor and optimize their own production machinery and equipment.

Pinpoint Laser Systems

www.pinlaser.com

Filed Under: MECHANICAL POWER TRANSMISSION, Lasers, TEST & MEASUREMENT

Tell Us What You Think!