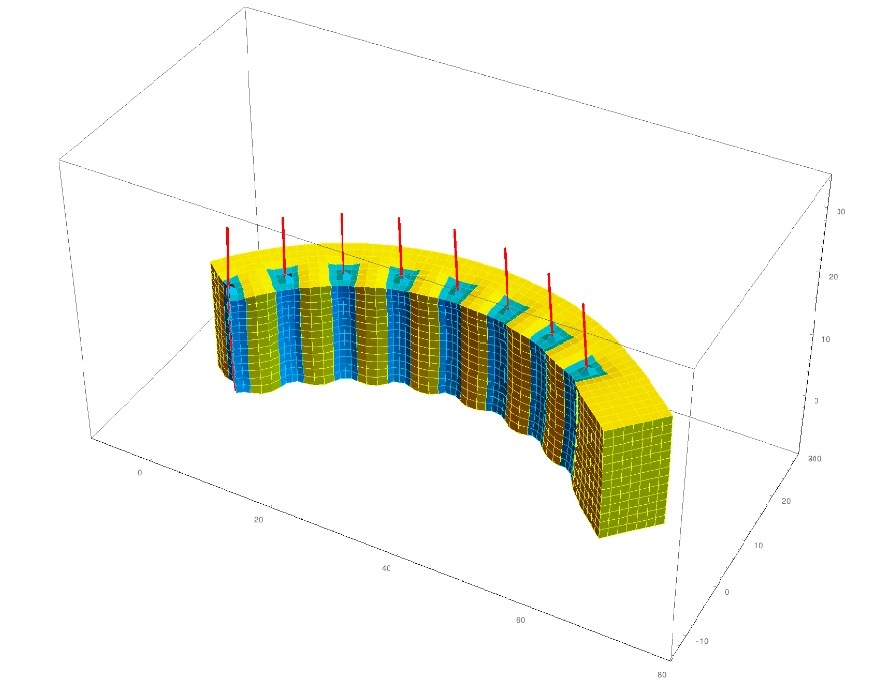

A diagram of the light- and temperature-sensitive composite shows how it can bend and shrink depending on what stimuli it is exposed to. Image credit: University of Pittsburgh

A new material developed at the University of Pittsburgh could be critical in 3D printing and robotics because of its ability to reconfigure itself based on stimuli such as light and heat.

Anna C. Balazs, professor of chemical and petroleum engineering at the University of Pittsburgh, and Olga Kuksenok, associate professor of materials science and engineering at Clemson University, published their research on the substance in the journal Materials Horizons in November.

They embedded light-responsive fibers coated with spirobenzopyran chromophores (color-sensitive molecules) in a temperature-sensitive gel. This allows it to behave slightly differently based on both light and heat. “Hidden” patterns in the material are unlocked by adding these movements tailored to light. They call it “4D printing,” in which the fourth element is time. The materials can be 3D printed, then easily changed into a new shape even after the print is complete.

This means that multiple behaviors can be programmed into it. For example, Kuksenok said, it might bend in one direction when exposed to light and the other direction when exposed to heat.

“On a conceptual level, our results provide guidelines for combining different types of stimuli-responsive components to create adaptive materials that can be controllably and repeatedly actuated to display new dynamic behavior and large-scale motion,” Balazs said.

The researchers also think that this can be used to good effect in “soft” robotics. Next, they will work on arranging the embedded fibers in order to create a structure that can grip like a hand.

“Robots are wonderful tools, but when you need something to examine a delicate structure, such as inside the human body, you want a “squishy” robot rather than the typical devices we think of with interlocking gears and sharp edges,” Balazs said. “This composite material could pave the way for soft, reconfigurable devices that display programmed functions when exposed to different environmental cues.”

(Via E&T Magazine)

Filed Under: Materials • advanced