By Laura Carrabine, Senior Editor and Leslie Langnau, Managing Editor

For industrial applications, wireless sensor networks are not quite as easy to install as the wireless connectivity on your personal computer. Industry experts speak out on what is needed for wireless operation.

Despite the buzz about wireless sensor networks in the process world, where are we in regard to development for the discrete manufacturing world? Visionaries focus on long range scanning of sensor data with battery life that runs ten years or more. Others dream of using wireless networks to totally replace Ethernet cabling. Pragmatists look to install something now to take a measurement they could not take before.

When installing sensors onto a network, one way to reduce wires is to use nodes and gateways. Sensor manufacturers, like Banner, offer a variety, like the DX80 system, that can suit your wireless connection needs.

Wireless sensor networks (WSNs) are expanding the reach of wireless, even into some areas of discrete manufacturing. But gaps in technology and capability remain. According to several manufacturers of wireless compatible devices, three trends will affect wireless networks in the next two to five years:

• The multiple wireless protocols of low-power wireless networks should converge, with better integration with existing standards like the Internet Protocol (IP).

• Wireless nodes will gain additional CPU processing capability and local storage.

• The above-mentioned gain in capability will push greater development in power management and harvesting technologies.

Buyer beware

The arena of wireless sensor networks is not well defined, noted Bob Gardner, Sr. Product Manager for Wireless at Banner. The goal is not to simply replace Ethernet cable in a factory or connect a sensor using the 802.11g protocol.

The idea of wirelessly connecting devices, in a manner similar to that of wirelessly connecting iPhones, cameras, and media players to a PC is attractive. But, while you can push a lot of data through this type of setup, it is usually a system with high bandwidth, high latency, shorter transmission distances, and low response time. It is not a practical approach for industrial applications because of the high latency.

Connecting a PC to a WIFI network does not necessarily mean you can use the same technology to connect sensors. Not many sensors offer wireless connectivity or can easily connect to a wireless network. Instead of making a temperature sensor “wireless,” for example, a better option is to use a wireless node that interfaces to the sensor. Noted Gardner, “We need a wireless infrastructure rather than alter every sensor to be wirelessly enabled. This is an area we are examining, in terms of factory automation.”

There are physical layer protocols that can be used in a wireless arrangement. The protocol on top of these networks, though, has not been defined well. The necessary drivers have not been developed for sensors to operate on the available protocols.

Banner handles the request for such sensors through its remote I/O system that interfaces to standard sensors, such as proximity sensors. The remote I/O system polls sensors regularly and transmits data to a control.

The remote I/O system includes nodes and gateways. The nodes can wirelessly connect to several sensors. The gateway functions like a master for the network segment. A User Configuration Tool (UCT) is used to map inputs and outputs between nodes and gateways. As with most arrangements, you must consider line of sight and transmission range when you architect your network system. This system can cover an area the size of a large automotive plant.

With the DX80 system the nodes automatically take analog or digital signals from one node and represent them on the other node without going through wires. The gateway polls the sensors every 62.5 ms. One I/O module polls the various sensors, which reduces cabling.

Battery powered sensors can be kept in “sleep” mode to conserve power. A radio communicates with its gateway at defined intervals and powers down when not in use. Banner uses lithium D cell batteries. Some of its thermocouple sensors can last eight years, depending on how often they are turned on and off.

“We looked into the SP100 protocol for our nodes, said Gardner, “and we have a system that works on the bench, but those protocols are big and complex, so we end up with low performance and high cost. With our DX system, all you need to use is EthernetIP or one of the Modbus versions.

“We have found that control applications are more difficult in the wireless world. You can create guaranteed timing in a wired system. For example, you might drop 1 in 10,000 packets in a wired system, where with wireless, that rate could be 1 in every 50, even with spectrum hopping and all the other techniques used to improve transmission. So you have to decide how many packets can be dropped before it registers as a network failure.

“Our guidelines are that if your application requires 1 to 10 ms response, go wired. If it requires 10 to 100 ms, wireless could be an option. If response times can be 100 ms or longer, then wireless is a strong candidate.”

“I refer to most working wireless applications as clipboard replacement. You are gathering data that would be too expensive to gather through cables. Fork lift truck tracking, for example, or monitoring operation hours, ensuring constant temperature during product movement, measuring temperature in a freezer, and so on.”

Machine monitoring in the factory is another application. Very small machines don’t require monitoring through a network, and big machines are connected to Ethernet. It’s the in between segment, where parts of a process were not monitored before that you would like data from. Motors that are having trouble on a conveyor system, for example. A control may not have feedback on the motor temperature. So, a node and thermocouple will measure the motor temperature.

Wireless is not limited to the process industry

“I don’t think process is the industry to focus on for wireless, although most people in process think it is,” said Robert Jackson, Senior Product Manager for Wireless and Energy, National Instruments. I’m also amazed that people compare wired to wireless.”

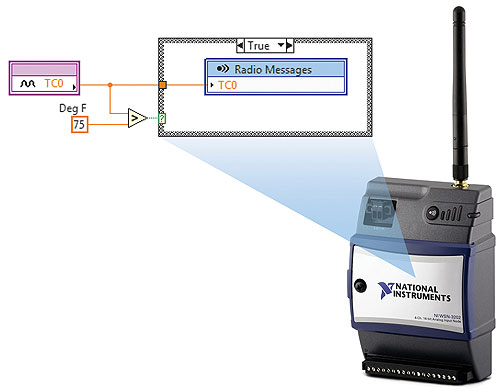

LabView from National Instruments is one way to navigate various network protocol requirements between sensors and the popular protocols. It supports all protocols and can make the differences among them invisible to the end device, such as the sensor.

There are many applications that can benefit from wireless because of the cost of wires or because it is too difficult to install wires into an area. There are several non-control applications in the discrete market. For example, measuring parts of a system to improve uptime or alter the approach for greater efficiency, like machine trending, power consumption, monitoring rotation equipment, and so on. “The industry should be exploring these applications before tackling control, continued Jackson. “What we see is the ability to get measurements wirelessly that is the big deal. Wireless technology is finally at the point that companies are putting product into the marketplace, and where that product can actually do what we think it can do.

“But a big concern that we see from customers is the question of longevity – how long will the hardware be available? There are not enough large players in this market yet.”

Another challenge is the need for companies to thoroughly inform customers about their product. Designing the system, or architecting, is important. To create a robust network architecture, it is crucial to know the differences among all the wireless standards. “For example, 802.11 has a large bandwidth; we can do 51.5 kilosamples/second on four channels for a transmission speed of about 7 Mbs. Dropped packets are still a concern. So a problem can show up in the transmit and retry functions; you need to architect the system to not have redundant loops that impede throughput.”

Another one; throughput consumes power. Know how much you really need.

The major factors to consider are bandwidth, power, and throughput tradeoffs. They vary between systems. “Often, the visionaries are just wrong about what their systems will really do,” said Jackson. “But the pragmatists know this and will work with what is available while pushing the visionaries to improve their products.”

An issue with sensors is that some intelligence is needed to convert raw data into a useful measurement. “LabView can be used to turn the data into a measurement,” said Jackson.

“We think it is better done here because you can put in whatever algorithm you need rather than wait for developers to create hundreds of algorithms for each sensor. This concept is also scalable.

Power management is a big issue with wireless. “The tradeoff we see coming will be in sensor capability versus power consumption. Customers will demand more of sensors and will be willing to trade capability for battery life.”

“The improvements we see coming for power management are lower power processors, and radios to transmit more data with less power usage, and energy harvesting.”

“There are three strong areas we see for energy harvesting:

• Where the power device works off vibration, such as piezoelectric cells harvesting energy from the vibration of machinery.

• Magnetic induction from power devices like drives. Two or three companies offer products that harvest energy from a moving motor.

• Heat flux, which generates a bit less power than the vibration techniques. This technique takes advantage of phenomena like the Seebeck effect (thermoelectric effect).

But with wireless, you will still need batteries. Energy harvesting will probably not be powerful enough to replace batteries, but they can augment them.”

Network architecture, again, is crucial. Mesh and smart grid are two popular topologies. But each has drawbacks. One type of mesh network has the entire network go to sleep when not needed. The problem is the time it takes to wake up the network for operation. Your fastest measurement point will depend on how fast the slowest node wakes up. With a smart grid, certain portions of a mesh design stay awake for faster data gathering. Routers, for example, stay on, so you still need a battery, but end nodes go to sleep and wake on an event-driven basis.

Another challenge with wireless is that the protocols can be a problem over the IP layer. IPSO, IP for Smart Objects, is a committee that is working out some of these issues. “But you can always use LabView for interoperability,” noted Jackson. “Labview supports all protocols and can make the differences among them invisible to the end device.”

Interoperability is still a challenge

Paul Brooks, Rockwell Automation’s Business Development Manager for the Networks Portfolio says that configuring interoperable wireless sensor networks requires a bit of tweaking for proper function. One issue is shared media. When organizations used cables, interoperability was not an issue because cables were installed side by side.

“You don’t have that luxury in a wireless environment. So the first element of interoperability is co-existence in a wireless space. If you have four devices with co-existence ensured, two pairs of devices can communicate with one another in the same free space in the same air. But, two pairs cannot necessarily intercommunicate. That is the second part of interoperability. Can the two pairs of wireless devices actually communicate with one another and exchange data? In an ideal world, the answer would be “yes.” But, that idyllic situation doesn’t exist.”

Tradeoffs must be made. Compare the needs of a wireless level transmitter, for example, with the needs of a drive remotely controlled through a wireless link. The level transmitter is an unpowered device, so it needs a battery that can supply power for years.

Conversely, a drive must control flow in real time and get updates from the host system every 10 milliseconds, 50 milliseconds, maybe every 500 milliseconds. Batteries are not a concern because the drive is a powered device. “But tradeoffs are needed to accommodate the volume of communications,” said Brooks. “Complete interoperability, from the point of view of the devices talking to one another, is pretty much an unachievable objective. However, coexistence is still absolutely mandatory.”

There’s also the issue of adding nodes. The first big problem is that most wireless networks use a mesh topology, which means that when a device comes online, it has to find a communication path to the host system. It may go through many devices that it doesn’t “know about.” The second problem is battery life. If you’re looking for long battery life in an Internet mesh network, you might have to make other trade-offs because the devices go to sleep for a while and then power up. When they power up, they receive and transmit communications, and then go back to sleep. So, for a device to surmount the network, it must be synchronized into that wake up/sleep cycle of all the devices that are around it.

Thus, adding a device to a network can be quite time demanding. It can actually take several minutes to properly register a device into the network and synchronize it with all the devices it needs to work with. The other challenge is you will always need a person to configure the gateways to add these devices into the network.

Lastly, security is crucial. It is easy, by comparison, to detect security breaches in wired systems. In a wireless installation you can’t control where the communications physically propagate to, or at least you have limited control. Therefore, you need to put more electronic security measures onto your communications. Put logical software-based access control into your systems so that only people you know can connect to your wireless network.

Data everywhere

Ben Orchard, application engineer at Opto 22, agreed on the issue of the invisibility of wireless. “With wired systems, it’s easy to trace and observe what is going on,” he said. “With wireless, however, you have no idea what is running around your office or factory. We purchased some specialty equipment to visually reveal the wireless environment. It will be interesting to see this area mature.

This I/O and communications processor operates in distributed systems controlled by a SNAP PAC S-series or R-series controller, or it can also be used as intelligent remote I/O with Allen-Bradley Logix systems. As an I/O processor, it independently handles latching, counting, thermocouple linearization, watchdog timers, and PID loop control.

What is needed is a way to “hedge your bet” on wireless. “We need systems that offer wireless along with standard Ethernet interfaces. These types of systems provide the best of both worlds. Just like with a laptop, you can switch the radio on for wireless networking, or in cases where wireless won’t work, simply plug an Ethernet cable in for a traditional wired connection.

It’s an interesting proposition and one that significantly lowers the risk of deploying a wireless system. “Having both a wired and wireless option in one system is a great way to gain all of the hardware and compatible software you need, without having to construct a full-blown wireless infrastructure throughout the factory or facility,” said Orchard. “With one investment, you’ve suddenly got all the flexibility you need to communicate via Ethernet interfaces, wireless Ethernet, or a combination of both.”

Discuss this on the Engineering Exchange:

Balluff Inc.

www.balluff.com

Banner Engineering Corp.

www.bannerengineering.com

National Instruments

www.ni.com

Opto 22

www.opto22.com

Rockwell Automation

www.rockwellautomation.com

Another way to deliver data wirelessly

Comau Inc., Southfield MI, developed a flexible assembly machine architecture they call SmartCell. It consists of dedicated tooling in the form of compact “shoeboxes” that reside inside the cell. The SmartCell can hold 8 shoebox tools. Two tooling arms change the tooling; one arm works while the other reconfigures for the next step in the assembly sequence. This assembly cell makes it easier for the company to align production capacity to market demand.

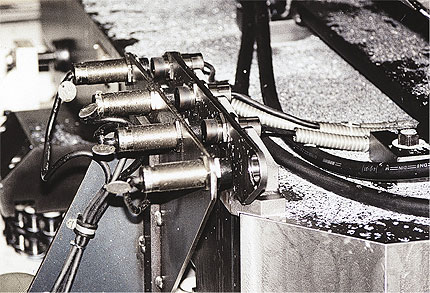

Workpiece position sensing in a machining center at MTU Friedrichshafen uses remote inductive couplers. Up to 16 sensors detect the positions and recognize the part to be machined based on certain features. After loading, the pallet is brought into the machining area.

A key engineering challenge was to minimize tool changeover time. The shoebox tools have up to 16 sensors and pneumatic clamps that require rapid and continuous changes. The engineers initially looked at using Profibus to communicate between the tool and sensors, but the availability time after a tool change was too long.<

Balluff Inc. (Florence, KY) recommended using a new connection technology called IO-Link. As a transparent extension of the Profibus network, IO-Link allows reliable connection through standard cabling to small machine-mount I/O blocks located directly on the shoebox tooling.

The remote inductive coupler can be used in applications that traditionally required wiring, such as end of arm tooling or on rotating machinery.

With that challenge solved, the next was maintaining reliability with the traditional mechanical pin-based connection systems even under the high volume of tool changes. Balluff developed a solid-state, non-contact connection device that communicated through IO-Link.

Operating off the inductive coupling principle, the remote inductive coupler passes power and data for the sensors through an air gap down to the shoebox tool. It can send signals bidirectionally, so the coupler can send an output as well as receive an input from a PLC. The Comau tool is passing serial signals, so this unit was passing 16 I/0 points plus diagnostics.

Because power and data are sent though an air gap, flex cables, slip rings, and other wired approaches are not needed.

Filed Under: Factory automation, CONNECTIVITY • fieldbuses • networks, Slip rings + rotary unions, Wireless • 5G and more, Energy management + harvesting, SENSORS

Tell Us What You Think!