There’s a lot of PR value in talking about green. Many consumers want green because they feel it’s the responsible thing to do. Machine builders want green, too, because that can be a buzzword for increased efficiency—and with today’s exorbitant fuel costs, that means a lot less capital going toward energy. Green marketing has become so large, in fact, that it’s spawned a whole new term, greenwashing. Greenwashing is the practice of falsely claiming to be green or spending more marketing the idea that you’re a green company than actually doing something environmentally responsible.

In between engineering writing gigs, I covered the hotel management industry for a few years earlier this decade, and the practice of greenwashing is prevalent there. So I think I have a bit more of a skeptical eye than most when I hear that a company is doing something green. But at a recent industry event in Philadelphia, I was pleasantly surprised to discover that the bearing company SKF is not only promoting itself as green, but seems to be truly putting its money where its mouth is.

From a manufacturing perspective, there are a couple of main green avenues to tackle. One is in the manufacturing perspective—aka, how well designed are the products? Do they achieve their structural and design goals without using excess materials or processes? And do they operate in as efficient a manner as possible, allowing the systems they are designed into to use a minimum of energy? The other is the company itself. Are its facilities (be they manufacturing, distribution, or operational) energy efficient? Or they all 1940s-era buildings, losing heat through ancient windows and pouring heated process water into a nearby stream?

SKF comes out a winner on both of these sides. Products released recently include integrated bearing sensor systems, electric cylinders, low friction engine seals, rotor positioning bearings, linear actuators, and low weight bearing hub units are all significantly more efficient then their predecessors.

Poul Jeppesen, President SKF North America, explained that the company is committed to its BeyondZero program, a strategy that endeavors to leave a positive effect on the economy. In fact, the company has grown 25% since 2006 and over that timeframe, the company’s total energy consumption has decreased 10% and its carbon footprint has decreased 25%. He highlighted some amazing parts of the program, from a global car policy that requires SKF employees to rent smaller, more fuel efficient cars to construction of their new North American headquarters, which earned a LEED Platinum rating. The building includes a geothermal heating/HVAC system, refurbished furniture, daylight harvesting and high efficiency lighting, and water-efficient fixtures.

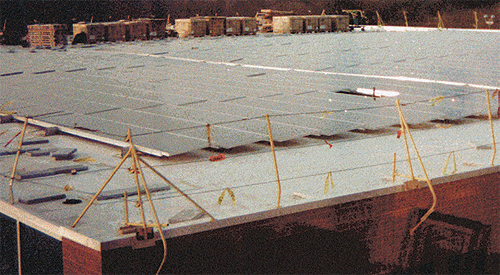

Did the company rest on its laurels after achieving Platinum status? The answer is no—the company recently spent $2 million to add solar panels to the building roof. To me, that shows more than PR, that shows commitment.

Do manufacturers have a responsibility to be green? Weigh in on Paul’s blog at the Engineering Exchange.

Paul J. Heney – Editorial Director

[email protected]

Filed Under: Commentaries • insights • Technical thinking, Green engineering • renewable energy • sustainability

Tell Us What You Think!