Improve efficiency and output by adding a new a material to your repertoire.

A number of new and interesting materials hit the market recently. Here is a sampling of a few of them that fall into several categories including electric signal conduction, lubrication, plastics, and industrial films.

Metallized Carbon Corporation, manufacturer of oil-free, self-lubricating, carbon-graphite materials, introduced its Silver Metcar. This material is a silver impregnated, carbon-graphite for electrical applications that require low resistance, low voltage drop, and low electrical noise. The material is well suited for dc motor brushes, non-welding electrical contacts, and rotary slip ring brushes or contacts in air traffic control radars, telecommunications systems, and satellite communications systems. The carbon-graphite has self-lubricating properties and the pure silver provides high and constant electrical conductivity.

With the growth of in-flight and at-sea television and internet services, there is increasing demand for antennas to track satellites. Ships, aircraft, rail systems, and other applications that require low electronic interference may soon use Silver Metcar.

The material is corrosion resistant, dimensionally stable, and has a heavy overload capacity. The product cannot melt or weld to another metal surface because the carbon-graphite base material will not melt. It can be silver plated so that it can be soldered to metal parts such as leaf springs or conventional brush holders.

Polypropylenes

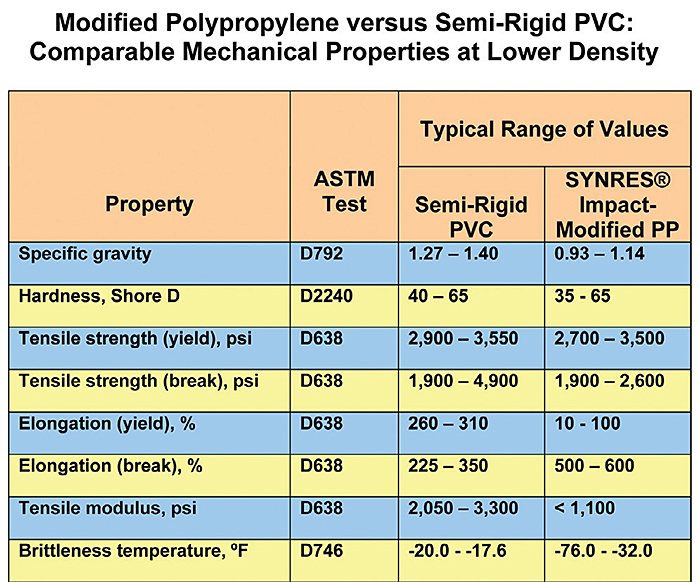

A new mineral-filled polypropylene (PP) compound provides an effective alternative to semi-rigid polyvinyl chloride (PVC) for applications where PVC is no longer an option. The Synres 1000 series compounds exhibit mechanical properties comparable to those of PVC in the 40 to 65 Shore D hardness range and low-temperature toughness and resistance to environmental stress cracking. Because PP has greater thermal stability than PVC, the new compounds are easier to process.

By combining LightSwitch Frontsheet film with c-Si solar cell technology, manufacturers and end-users get the best of both worlds — a high-performance PV module that meets lightweight requirements.

The new products cost more per pound than the PVC materials they would replace, however, part of the price difference is offset by a greater volume yield. Their average density is lower than that of semi-rigid PVC materials, and one pound of a Synres compound yields more finished product.

Typical applications include cove bases and molding in buildings and construction, protective edges, and “U” and “J” profiles. The compounds come in natural or pre-colored form according to customer requests.

Lubricants

Struktol TR 063 is a new lubricant that improves processing characteristics of filled and unfilled polyamides. Typical improvements at the compounding stage are reduced die build-up (“die bearding”) and die drool. For injection molding applications, you can expect to see better flow and mold filling versus typical lubricants such as metal stearates or amide waxes. The product is compatible with polyamides.

According to the company, TR 063 provides compounders and processors with a cost-effective process additive than can improve throughput and efficiency.

Struktol Company of America reports decreases in die build-up during compounding and good overall processing in extrusion and injection molding of finished compounds. Strand pelleting of nylon 6 and 66 compounds often results in die build-up after a short time. Struktol TR 063 added at 0.5% to 1.0% loadings minimizes this type of build-up allowing the processing to run longer without concern for contamination or discoloration.

In filled or reinforced compounds, the material reduces viscosity and improves dispersion, which leads to more consistent processing. The product has been shown to have minimum interaction with coupling agents often used with reinforcing products such as glass fiber. Stuktol TR 063 is designed to work in the temperature processing range of nylon 6 and 66 compounds. It can be added directly at the compounding stage or by the processor during part manufacturing. In pellet form, it can be added to extrusion or injection molding machines.

Ultrachem developed a new line of Omnilube food-grade rotary screw and reciprocating air compressor lubricants with improved wear, oxidation, and lubricity. The new products include Omnilube 32/46, 68, and 455. They meet all the requirements of the USDA and FDA H-1 regulations, 21 CFR 178.3570, conform to NSF specifications, and are approved by the Orthodox Union for Kosher use.

The Omnilube family of lubricants is a complete line of food grade oils and greases.

The products are synthetic compressor oils made from high quality polyalphaolefin (PAO) base oils with a proprietary additive package to maintain a long life. Depending on the rotary screw design, the oils deliver a service life of up to 8,000 hours in good operating conditions. They are well suited for meat, poultry, and food processing (H-1) plants and operations that use vacuum pumps. The products offer less varnish formation, low pour point, high flash point, and good compatibility with elastomers, seals, plastics, and paints.

Films

LightSwitch is a series of fluoropolymer films for lightweight crystalline silicon (c-Si) photovoltaic (PV) modules. Saint-Gobain will soon be submitting these modules for International Electrotechnical Commission (IEC) certification.

This table compares typical properties of semi-rigid PVC and Synres 1000 series compounds over a range of hardnesses

Conventional c-Si modules typically include a heavy glass front design requiring extra care in handling and increased installation costs. Ideal for lightweight solar modules, LightSwitch Frontsheet is a melt processable fluoropolymer that operates well in all weather conditions and is UV and chemical resistant. These transparent films provide frontsheets weighing as low as 0.1 kg/m2. At approximately half the weight of conventional materials, LightSwitch films allow c-Si PV module manufacturers to deliver a lightweight, high-performance product.

Metallized Carbon Corporation

www.metcar.com

Teknor Apex

www.teknorapex.com

Struktol Company of America

www.struktol.com

Ultrachem, Inc.

www.ultracheminc.com

Saint Gobain Solar

www.saint-gobain-solar.com

::Design World::

Filed Under: Slip rings + rotary unions, Materials • advanced

Tell Us What You Think!