By Rob Rix, Vice President, Lighting, Tyco Electronics Communications & Industrial Solutions, Harrisburg, Pa.

With high-efficiency LEDs, solid-state lighting is rapidly emerging as a major player in the lighting fixtures industry.

Although Solid-State Lighting (SSL) devices currently cost more than conventional incandescent lamps, SSL pundits have encouraged the electrical lighting industry to convert gradually from making simple lamps to producing more complex but considerably more efficient electronic SSL systems. And their argument is hard to dispute: If we don’t convert, the power plants now in operation and those hoped for in the near future, will not be able to supply the global demand for electrical power.

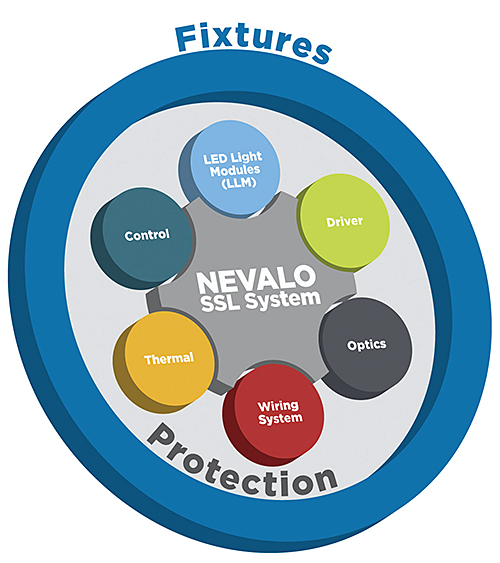

Several essential, interconnected technology areas of solid-state lighting (SSL) are brought together at the systems level for a successful solution.

(Courtesy: Tyco Electronics).

Fortunately, these efficient SSL systems are not new: They combine several readily available elements, such as LED light modules (LLMs) or light engines, drivers and control electronics, and optics. But, as manufacturers move away from their existing incandescent and fluorescent fixtures to develop new light fittings, they must also consider thermal management on a more serious scale, develop totally new electrical and mechanical designs, and contend with numerous unfamiliar industry standards and government regulations.

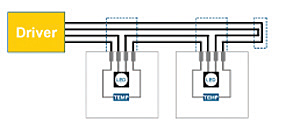

For multiple LED assemblies, multiple test points provide a more thorough means of verifying proper system operating temperatures. This special test board includes a connector on the right-hand side for transmitting data to a thermal test instrument. (Courtesy: Tyco Electronics)

The NEVALO system bus structure contains an integrated thermal monitoring circuit.

Transitioning to Solid State Lighting

As evident in many other industries, consumers expect the leading technology companies to respond to our needs with new products that use the latest technologies. And solid-state lighting looks like the best solution we have now for obtaining higher lighting efficiency. However, it comes with some caveats. For instance, lighting suppliers have seen how poorly the transition from incandescent lighting to the more efficient compact fluorescent lamp (CFL) technology had been handled. Suppliers have had similar trouble coping with SSL because it is even more complex than CFL. But, fortunately, the lessons learned from this process are now being applied to solid-state lighting: They recognized the need for a new approach.

What’s in it

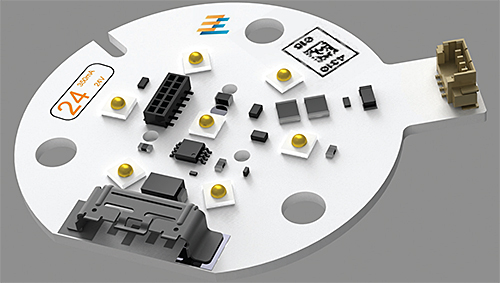

The LED light module is the heart of solid-state lighting. It is a subassembly that includes the LED light board (a PCB containing LEDs), a thermal interface, a socket, and matching optics. The socket optically aligns the LED light board, and the optical devices come in a variety of beam angles to best suit the application.

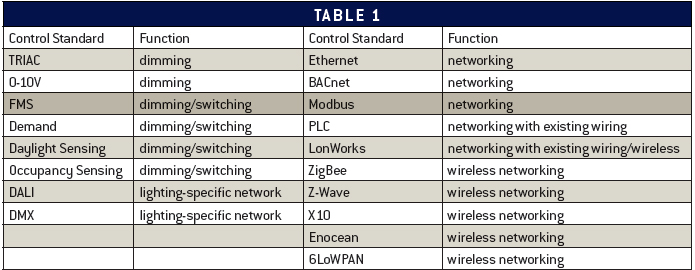

The driver module in an SSL system converts the utility ac power to the dc power required by the LEDs and the electronic circuitry. It also controls dimming, switching, and networking and provides thermal protection. For solid-state lighting to replace incandescent and fluorescent lighting in networks, SSL products must be compatible with all existing and emerging network controls. Fortunately, SSL lends itself readily to these communication techniques.

This is an exploded view of the components of a NEVALO CN58 LLM.

Thermal Design

Excessive temperatures degrade performance, shorten lifetimes, reduce the reliability of LEDs, and affect nearby circuitry and connectors. To keep LED temperatures within safe limits and increase reliability, large heat sinks are often required. Advanced SSL lighting designs use aesthetically pleasing heat sinks as well as a comprehensive thermal management system to monitor temperature, detect faults, and protect the light source.

Such thermal management is essential for SSL electronics. The LED’s critical junction temperature is deep within the package. Because this is not easily measured, a package (or outside case) temperature is normally measured instead, and the actual junction temperature is calculated using “known” thermal resistances for that device — and the controls are set accordingly. The maximum junction temperature for some LEDs can reach 150° C while the normal operating case temperature sits between -40 to 135° C. Each manufacturer determines the maximum junction temperature allowed for its LEDs.

In addition to reducing the operating life, high temperatures reduce the relative luminous flux (light output). For example, at a case temperature of 130° C, the output drops about 80% or more, depending on the color-temperature rating. Excessive or higher temperatures also increase the dominant and peak wavelengths and color temperature shifts.

To help designers with this task, NEMA recommends the location of specific temperature test points for LEDs. The temperature must be measured, monitored, and controlled by circuitry that incidentally increases the complexity of the SSL design, but also improves the performance, reliability, and lifetime of the luminaire. Specially designed test tools accurately record temperatures to verify that the temperature design has been accomplished correctly.

Wiring & Connectivity

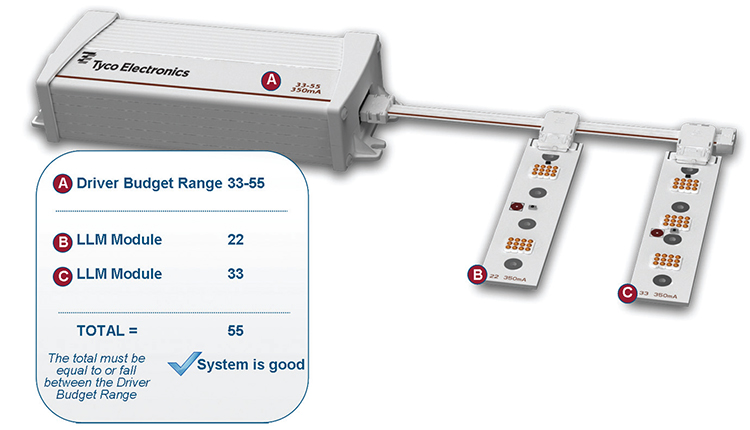

In an integrated SSL System, the wiring and connectors deliver power to the LLMs and provide a path for critical thermal monitoring and control signals. In a typical NEVALO wiring system, a low-profile, four-wire, 24 AWG (2.5 mm centerline) stranded ribbon cable connects LLMs to each other and to the driver module using insulation displacement crimps (IDCs). The system is keyed physically and color-coded to identify specific current ratings. The SSL system budget is another benefit of the NEVALO system that simplifies fixture design and reduces the chance for errors.

In the illustration, color-coding indicates that the right subassemblies have been selected. Because the drive module can handle 33 to 59 V, the system is within safe operating limits (under 59 V) according to Underwriters Laboratories (UL) Class II lighting.

SSL lighting controls address a variety of functions and network communications techniques

Solid-State Lighting’s future is bright. It is cheaper than incandescent lamps over the lifetime of the device, and SSL has the added benefit of substantially higher efficiency. Also, the next generation of SSL fixtures will take advantage of digital controls to provide color mixing within the white spectrum for warmer light in the morning and cooler light in the afternoon, or something in between. Yet another unique application for the next-generation of SSL is street lighting: Lights will increase in intensity and flash when a 911 (or police) call is made and brighten the area for first responders. At other times, SSL fixtures will automatically dim by 15% to save energy and reduce peak energy demand without the occupants sensing it. These and many other exciting possibilities, which are not possible with existing lighting sources, will come with solid-state lighting. Solid-state lighting offers a vast new opportunity for luminare manufacturers, although simultaneously presenting new and often unfamiliar (but surely solvable) engineering challenges.

This NEVALO SSL system budget shows how easy it is to verify an acceptable luminaire design. In this system design, users simply match the color codes and ensure that the LLM budget is within the Budget Range called out for the driver.

New efficiency standards and government regulations

The sales of new and retrofit SSL fixtures are expected to account for more than half of the $91 billion in estimated lighting sales for 2014 and further rise to 75% of the market share by 2019. Regulations coupled with higher energy costs and lower SSL costs will dictate the pace of this change. Governments most aggressively pursuing the elimination of incandescent bulbs include those in the European Union, Japan, United States, Canada, Australia, and the Republic of China.

In 2009, restrictions on the sale of incandescent bulbs began in most of Europe based on Directive 2005/32/Ec of The European Parliament and of the Council of 6 July 2005. Australia was the first country to announce a ban for incandescent bulbs. The ban went into effect in 2010. Canada was the second country to announce an incandescent bulb ban that goes into effect in 2012.

The Japanese government implemented a series of subsidy policies to pursue the commitment it made in the Kyoto Protocol. In December of 2006, the JELMA (Japan Electric Lamp Manufacturers Association) announced four proposals to substitute less efficient lamps with higher efficiency alternatives. On April 5, 2008, the Minister of the Ministry of Economy, Trade, and Industry (METI) announced “the replacement policy for Incandescent to CFLi by 2012”.

An energy bill passed in 2007 by the U.S. Congress, the Energy Independence and Security Act of 2007, effectively bans the incandescent light bulb as we know it by 2014. Initially, the conventional 100-watt bulb will be obsolete in 2012. The incandescent light phase-out process ends with the elimination of 40-watt bulbs in 2014.

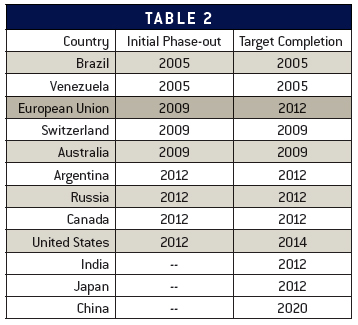

The statutory elimination of incandescent bulbs is occurring on a global basis.

China has also announced plans to phase out incandescent bulbs by 2017. Table 2 shows a summary of these as well as the incandescent bulb elimination plans for other countries.

Discuss this on The Engineering Exchange:

Filed Under: Lights • signal lamps • indicators, ELECTRONICS • ELECTRICAL

Tell Us What You Think!