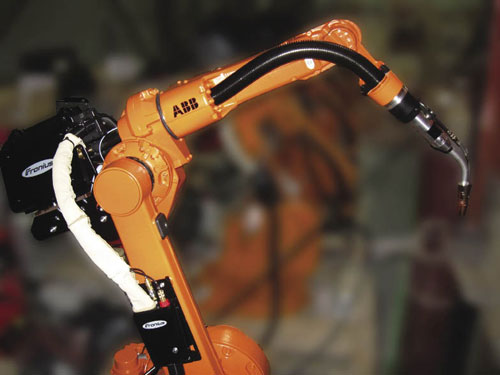

ABB Robotics and Fronius International, a worldwide welding equipment company, have entered a global agreement to collaboratively develop fully equipped robotic welding packages, and support both new and existing customers with advanced technology. The welding packages will be specially designed to provide modular, cost-effective solutions for companies to more easily initiate or upgrade a robotic welding system. Fronius equipment will be featured at all certified ABB Robotics welding lab locations, allowing customers to conduct robotic welding trials on the latest equipment available.

ABB is featuring two new offerings using Fronius technology. The first, the ArcPack U2 with the ABB IRB 1520ID dedicated arc welding robot with Fronius equipment, is a modular, entry-level welding cell with two fixed stations. The standard twin table configuration suits small components and can be provided as either a complete welding function package or an integrated cell at an affordable price. The second product is an EthernetIP integrated communications interface for programming and operating Fronius power sources on the FlexPendant, ABB’s HMI. This single point of programming will allow weld data to be controlled by the FlexPendant through the interface. FlexArc cells and welding packages can be equipped with the ABB-Fronius EthernetIP interface option.

“ABB Robotics and Fronius have been working closely together for many years,” said Erwin DiMalanta, senior manager, ABB Robotics. “This formal agreement, featuring two global technology leaders in their respective segments, will take the relationship to the next level, bringing welding segment customers more affordable access to leading edge equipment, and far more intuitive, user friendly operating interfaces.”

ABB will continue to provide integrated welding solutions with other major suppliers of welding equipment.

Fronius

www.fronius.com

ABB Robotics

www.abb.com/robotics

Filed Under: The Robot Report

Tell Us What You Think!