ABB Robotics has increased the top payload of its IRB 1600 from 8 to 10 kg, expanding the performance of this versatile robot to heavier part applications. The IRB 1600 is used in a variety of applications including machine tending, material handling, arc welding and cutting. The increased payload is available in both the 1.2-m and 1.45-m reach variants, and will allow the robot to handle larger parts and end-of-arm-tools with no sacrifice in accuracy and speed. ABB says this will achieve up to 50% better cycle times than competitor robots of the same class.

ABB Robotics has increased the top payload of its IRB 1600 from 8 to 10 kg, expanding the performance of this versatile robot to heavier part applications.

The IRB 1600 provides a combination of acceleration and accuracy, eliminating the common trade-off between these two primary performance metrics. The company’s second generation QuickMove motion control technology and low friction spur gears allow the IRB 1600 to speed up and slow down faster than other robots, saving time while moving between tasks and improving cycle time. And the second generation TrueMove technology ensures that the robot will maintain the same path at all speeds, eliminating the corner-cut paths that most robots default to at high speeds.

“Whether it’s a small job shop or a huge tier one manufacturer, the challenges for these industries are the same. Produce quality parts at a low cost,” said Terry Crunk, machine tending specialist, ABB Robotics. “This upgrade, though seemingly insignificant, will be just enough to give the end-user a valuable competitive advantage for a number of different robotic applications, particularly for machine tending applications.”

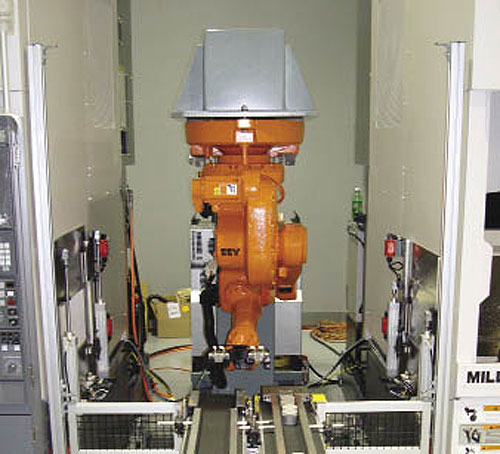

The upgrade enhances the IRB 1600’s other advantages such as solid protection for use in harsh environments (IP 67 and Foundry Plus 2), and the ability to be invert or side mounted, on a shelf, a wall or other existing structures. The compact 1.2-m reach variant makes the robot more dexterous in confined spaces for improved reach and flexibility. The IRB 1600 is also more energy efficient and provides lower noise levels than comparable models.

ABB Robotics

www.abb.com

Filed Under: Factory automation, The Robot Report, MORE INDUSTRIES, Motion control • motor controls

Tell Us What You Think!