The batteries traditionally used to deliver high rate power to single-use military applications have remained virtually unchanged for decades, creating the need for alternative power sources.

A Systematic Approach is Needed

Single-use military applications range from ordinance guidance systems to torpedoes, smart ammunition, mines, sonobuoys, unattended ground sensors, UAVs, artillery fuses, active decoy systems, trajectory correction add-on kits, proximity fuses for bombs, and dispersed munitions sensors. Each application is unique, so when specifying a primary battery for a single-use military application, you need to evaluate all available technologies to ensure optimized results.

Significant advances in commercial battery chemistry are enabling innovation in military applications. Photo: Tadiran

The most common battery technologies that power single-use military applications include:

- • Reserve and thermal batteries

- • Silver-zinc batteries

- • Spin activated batteries (lead acid and lithium thionyl chloride)

- • High-power lithium metal oxide batteries

Specifying the ideal battery is a multi-step process that starts by evaluating anticipated performance, quality, and safety criteria in accordance with applicable MIL-spec and/or third party certifications. Start by developing a prioritized checklist of desired battery attributes, including:

- – Voltage, capacity, and energy density

- – Size, weight, and packaging requirements

- – Required service life and/or shelf life

- – Temperature range and other environmental considerations

- – Requirements for instant activation or testing for system readiness

- – Cost of ownership

Your comprehensive checklist will provide a benchmark for comparing the battery technologies commonly used in single-use military applications, which are summarized below:

Reserve/thermal Batteries

The term ‘reserve battery’ actually encompasses a range of different technologies and chemistries, including thermal, lead-acid, silver-zinc and lithium thionyl chloride chemistries.

With reserve batteries, the electrolyte is stored separately from other active ingredients, typically using a pyrotechnic device to initiate and maintain the chemical reaction. The active ingredients within a reserve battery remain inert, thus creating the potential for almost indefinite shelf life. However, there are significant trade-offs, as reserve batteries cannot be tested for system readiness without fully depleting the battery. Battery activation is also delayed until the chemical reaction occurs.

One common type of reserve battery is the thermal battery, which contains a metallic salt electrolyte that is inert and non-conducting in a solid state and at ambient temperatures. Once activated by a pyrotechnic charge delivered by a squib, the metallic salt electrolyte becomes molten, quickly transforming into an excellent ionic conductor that yields high rate power of relatively short duration, ranging from a few watts to several kilowatts, depending upon battery chemistry and size.

Thermal batteries are preferred for their ruggedness, safety, reliability, and deliver extremely long shelf life. However, due to the use of squibs and the need to keep the electrolyte continually molten at 400°C to 700°C for optimum conductivity, thermal batteries are somewhat bulky to incorporate a squib and layers of insulation that retain heat to keep the electrolyte molten, while also protecting surrounding components from heat-related damage.

Silver-zinc Batteries

Silver zinc batteries are complex to manufacture since they require a gas generator, tubular electrolyte reservoir, manifold, battery block, vent, and heater system. As a result, silver zinc batteries tend to be expensive and require long production lead times. Silver zinc batteries also have performance limitations due to their low energy density.

Spin-activated Lead-acid Batteries

Military fuses and certain marine applications are often powered by spin-activated lead-acid batteries that store the electrolyte (typically flouroboric acid) inside an ampoule or bladder. When the projectile is fired, the bladder slices open and the electrolyte is distributed throughout the cell stack by centrifugal force. Spin-activated batteries manufactured using lithium thionyl chloride (LiSOCL2) chemistry are used to power minelets or communication jammers, which are propelled by artillery shells and equipped with parachutes to ensure a soft landing. The main advantage of a spin-activated battery is its ability to deliver high rate power for extended periods of time with no voltage delays. Spin-activated batteries also have major drawbacks: relatively low capacity, delayed activation, and the inability to be tested prior to use.

High-power Lithium Metal Oxide Batteries

Lithium metal oxide batteries are now available that use commercial off-the-shelf (COTS) technology to deliver high current pulses and high rate energy.

Constructed in a cylindrical shape with a carbon-based anode, a multi metal oxide cathode, organic electrolyte, and a shut-down separator, lithium metal oxide cells feature an extremely high energy-to-size ratio, and are available in three standard sizes: AA, CR-2, and 20 mm length. For example, an AA-size lithium metal oxide cell can deliver up to 2 Wh of energy with a nominal voltage of 4 V, a discharge capacity of 1,100 mAh, including the ability to generate 15 A pulses and 5 A continuous current.

Lithium metal oxide batteries provide long-term reliability, offering up to 20-year storage life due to a very low annual self-discharge rate. These batteries feature a wide temperature range (-40ºC to +85ºC), and permit instant activation without the need for squibs or gas generators. Once installed, they can remain “on” continuously while drawing nominal amounts of daily current to permit periodic testing for system readiness, thus reducing the number of “duds” in missile guidance systems. These batteries also comply with MIL-STD 810G specs for vibration, shock, temperature, salt fog, altitude, acceleration (50,000 gn), and spinning (30,000 rpm), and meet UN 60086 standards for crush, impact, nail penetration, heat, over-charge and short circuit. In addition, lithium metal oxide cells do not generate high internal temperatures, so there is no need for the thermal insulation layers common to reserve/thermal technologies.

Here are some real-life case histories involving lithium metal oxide batteries:

BAE Systems/ODAM 60mm mortar guidance systems: Under DARPA’s Optically Directed Attack Munitions (ODAM) project, BAE Systems undertook a development and integration initiative to demonstrate the feasibility of a laser-guided, low cost 60-mm mortar round. BAE Systems selected CR-2 sized high power lithium batteries to power the system’s laser-guided optical seekers. Lithium metal oxide batteries were chosen over CR-2 consumer type batteries because their ability to operate in extremely cold environments (-40°C), with up to four times longer shelf life (20 years vs. 5 years).

Unmanned aerial vehicles (UAVs): UAVs widely utilized for unmanned air reconnaissance incorporate a battery-powered back-up guidance system that allows an aircraft with main power failure to glide to a safe landing. To power the UAV’s emergency recovery system, a 32 V/480 W custom battery pack was developed using 96 AA-size lithium metal oxide batteries: resulting in a highly compact power supply that weighed just 2 Kg including the metal enclosure. (Figure 1)

Figure 1. The UAV’s emergency recovery system is powered by a 32 V/480 W custom battery pack using 96 AA-size lithium metal oxide batteries inside a metal enclosure.

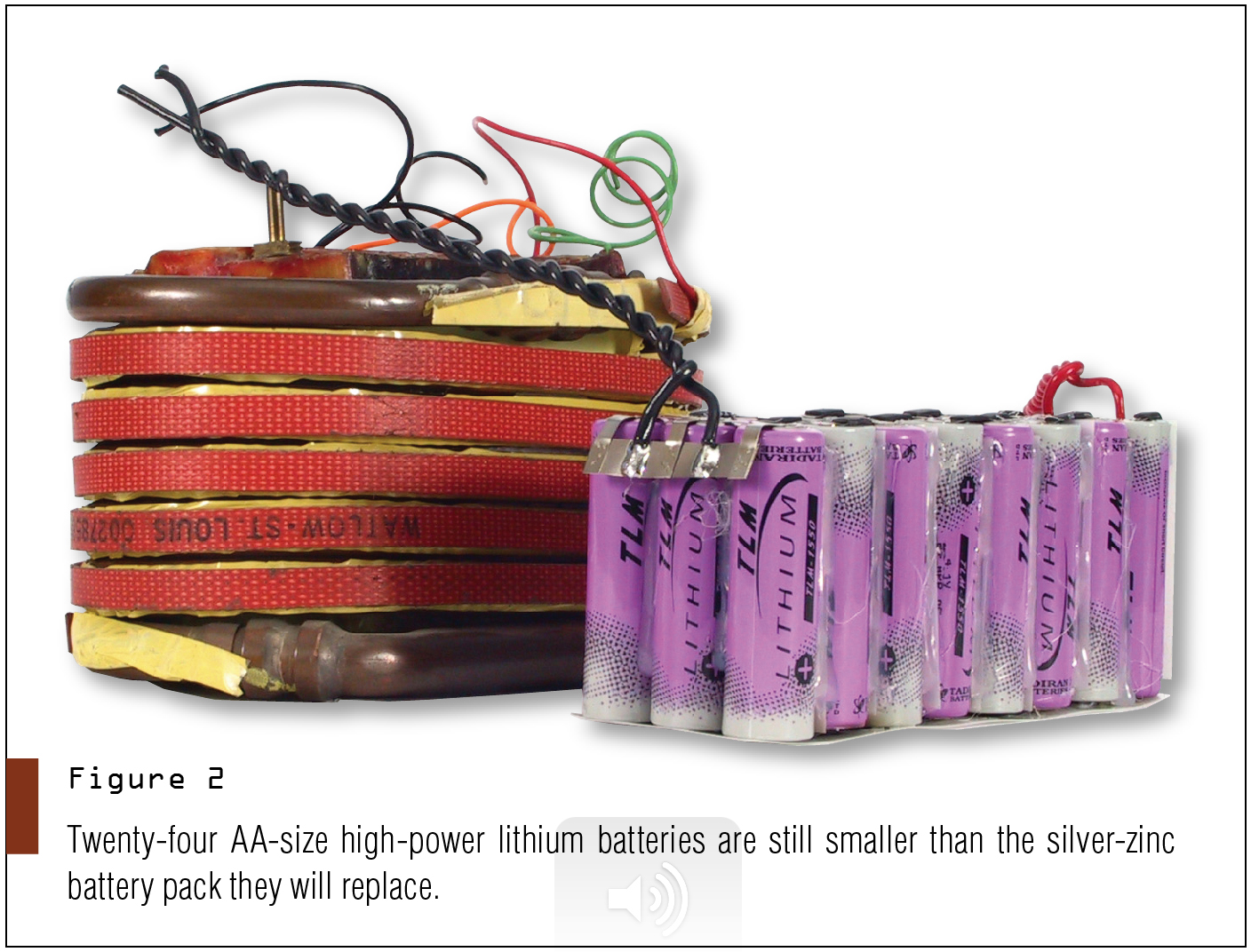

Powering missile systems: Air-to-ground missile systems previously powered by large silver zinc battery packs can be converted to a pack half the size using high power lithium batteries, enabling shorter design and production cycles and major cost savings due to simplified manufacturing and greater availability. This solution also led to reduced weight and volume, and greater energy density. (Figure 2)

Figure 2. Air-to-ground missile systems can use high power lithium batteries to replace large silver zinc battery packs, shortening design and production cycles and reducing costs due to simplified manufacturing and greater availability.

Guided artillery shells: large reserve batteries are currently utilized to deliver medium power, high capacity, and low current pulses to power the artillery shell’s guidance system. Converting to a lithium metal oxide battery pack would enable greater design flexibility, major size and weight reductions, and significant cost savings.

The introduction of the lithium metal oxide battery has enabled single-use military systems to become more miniature, cost effective, and reliable with the ability to perform periodic system readiness tests. However, as with any new technology, careful evaluation is required to ensure that the right battery is being selected based on application-specific requirements.

Filed Under: Aerospace + defense