A new generation of compact, custom-built, high-performance, air-cooled heat sinks are the result of a multimillion-dollar development contract from the Defense Advanced Research Projects Agency (DARPA).

The heat sink products reflect advances in the development and commercialization of active heat sink technologies, achieved as part of the DARPA Micro-technologies for Air-Cooled Exchangers (MACE) program. Thermacore participated in this program. After the results of the company’s initial MACE demonstration step exceeded DARPA expectations in early 2011, it developed four varieties of passive heat sink products, all representing improved airside heat transfer performance over existing state-of-the-art heat sinks. The design integrates Therma-Base Vapor Chamber technology within a 3-dimensional thermal solution, with vapor flow spreading heat both laterally in the base and into planar appendage heat pipe blades. High-density fins are attached to the planar blades to improve thermal performance.

“We’re excited about the possibilities of this new design for meeting difficult microprocessor cooling challenges, including those found in military applications,” said Nelson Gernert, vice president of engineering and technology, Thermacore. “But it’s also important to note that a key element in this new product line is the vapor chamber technology we’ve used for many years.”

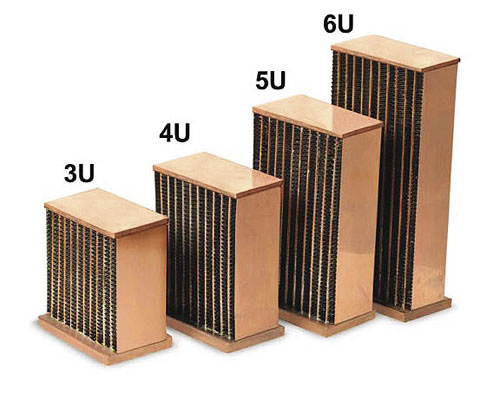

The MACE-developed heat sinks will be available for insertion into four chassis cooling formats, 3U through 6U, and demonstrate thermal uniformity and low thermal resistance. These compact air-cooled heat sink products will handle heat loads from 250 to 2,000 Watts depending on model. Although the design and layout of the heat sinks is novel, their construction involves standard materials such as copper (wall and wick) and aluminum (fins); the working fluid can be water or methanol. Mounting features are customizable for each application.

Typical thermal applications for the new product line include cooling avionics in manned and unmanned aircraft, vetronics in ground vehicles, military radars, medical electronics and computer server microprocessors.

Thermacore, Inc.

www.thermacore.com

Filed Under: Aerospace + defense

Tell Us What You Think!