By Derek Lee, Product Engineer, Yaskawa Electric America, Inc.

Are there other advantages to digital networks besides wiring savings? Here are five of the most important.

Digital networks reduce wiring, saving you time and money over traditional discrete and analog hardwiring. But are there other advantages? With digital networks, and in particular with EtherCAT – an Ethernet-based high-speed open digital network –there are a host of advantages. Here are five of the most important.

1. Better synchronization

A motion control network typically has a number of motor control devices, each of which is connected to a main controller. Synchronization among these devices enables coordinated motion, and the more precise the synchronization the better the overall motion performance of the system or the machine.

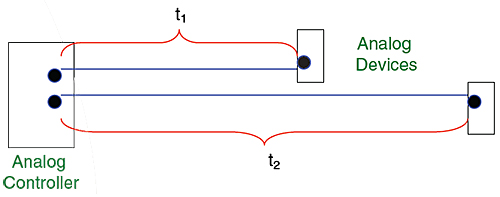

In a hardwired topology, t1 does not equal t2. The Devices times are not equal because the signal needs to travel a longer distance.

In a hardwired system, the only way to synchronize motion is to have the same length of cable between the controller and each device, so that the execution signal takes about the same amount of time to reach each device. The controller also has to fire an execution output to each device, simultaneously. This scheme is inherently imperfect with built-in errors specifically introduced by the difficulty of coordinating simultaneous delivery of execution signals to each device.

With a digital network like EtherCAT, synchronized timing among distributed clocks on each motor control device (such as the Yaskawa Sigma-5 servo amplifier) and the main controller master clock allows each device to begin execution of a command from the main controller at the same time. This action is possible because the distributed clocks on each device use an automatically calculated offset.

2. Faster data transfer

EtherCAT supports various forms of data transfer protocols through tunneling, including HTTP, FTP and TCP/IP. Data transfer rates are fast at 100 Mbps. Unlike hardwired systems, digital networks in general and EtherCAT in particular support transfer of data, such as device parameters, in addition to exchange of real-time motion control commands.

EtherCAT topology: t1 = t2 The times are equal because each includes an automatically calculated offset

EtherCAT Data Transfer

Tuning parameters and other data, like diagnostics, can be transferred through the high-speed digital network connection.

For example, an application might require transfer of tuning parameters from the main controller to one or more motor control devices. Because EtherCAT transfers data quickly, all the tuning parameters from the EtherCAT master main controller could easily be transferred from the main controller to each motor control device. If one motion control device was tuned and optimized for best control, then that device’s parameters could be transferred to the main controller for retransmission to all other motion control devices.

Transfer of tuning parameters and other data can be performed at any time without interruption of real-time motion control because data transfer is subordinate to critical data like real-time motion control information.

In addition, the data transfer feature opens up the possibility of sending device diagnostics to the main controller. This allows the controller to display which device on the machine has a problem, along with the exact nature of the problem.

EtherCAT Digital Data

Data are received exactly as sent, so the data are accurate and precise.

3. Greater accuracy and precision

Data in hardwired analog signals is subject to attenuation and signal fluctuation due to wire resistance and other sources of voltage changes. These conditions have a direct negative impact on accuracy and precision. For example, a 10 Vdc signal from a servo motor controller to indicate 6000 rpm might be attenuated down to 9.9 Vdc by the time it reaches the main controller, effectively indicating a motor speed of 5940 rpm. On top of that, the signal could be changing between +/- 0.05% or more due to voltage fluctuations.

However, the data in the EtherCAT fieldbus network is not affected by attenuation or fluctuation. The data undergo appropriate error checking. For example, the main controller could command one or more of the motor control devices to run a motor at 6000 rpm. The exact desired speed rate would be received at each motor control device in a digital format with no error. The device would then convert this digital signal back to the desired analog speed rate of 6000 rpm.

4. Improved data checking

If the transmitted data in a hardwired analog system are affected by noise in a servo motor application, then the motor’s position will drift over time. It can be difficult to detect this drift, as in most machine automation applications the first indication will be production of poor quality parts.

Hardwired Analog Data

Data are affected by attenuation and signal fluctuation, they are neither accurate nor precise.

Hardwired Analog Data

Noise-affected data goes undetected by the receiving device, so the end device is affected.

With EtherCAT, there is an immediate indication of noise affects on data transmission. EtherCAT uses a system of checks to verify data integrity. Any inconsistencies, typically caused by electrical noise, are detected and trigger a notification.

In many automation systems, data transmission is subjected to low levels of electrical noise that don’t have a significant negative impact on performance. To accommodate these situations, systems like the Yaskawa Sigma-5 EtherCAT servo amplifier let you set a range of allowable consecutive missed packets.

The main controller can perform automatic analysis of missed packet and other data transmission information. The analysis can give you predictive diagnostics of data transmission issues, allowing repairs to be made on a proactive as opposed to a reactive basis.

EtherCAT Data

Noise-affected data are detected by the receiving device, and the user is notified.

5. Standard cables and connectors

In many cases, cables with proprietary connectors are needed to hardwire discrete and analog signals from the main controller to the motor control devices. These custom cables and connectors can be difficult to obtain and expensive to stock.

EtherCAT uses Ethernet cables and connectors, which are inexpensive, widely available and quickly deliverable. Maintenance personnel tend to be familiar with standard Ethernet hardware, so installation and repair proceeds more quickly.

When comparing hardwiring to digital networks, the most obvious advantage of going digital is wiring savings. This is particularly true in motion control systems where scores of wires and cables are often needed from the main controller to each motor control device. Replacing these wires and cables with one standard Ethernet cable reduces wiring costs, installation time and wiring errors. It also makes the entire motion control system easier to modify, as new devices only require expansion of an existing digital network.

But for many applications, the most significant benefits aren’t associated with reduced and simpler wiring. Better synchronization, faster data transfer, more accuracy and precision, improved data checking and the ability to use standard cables and connectors can be even more important in certain applications than wiring savings.

Yaskawa Electric America

www.yaskawa.com

::Design World::

Filed Under: Factory automation, CONNECTIVITY • fieldbuses • networks, Motion control • motor controls

Tell Us What You Think!