For years, pressure vessels have been indirectly involved in making our lives better.

Being utilized in water treatment plants, food processing and power plants, these pressurized containers have long been the hidden force behind the factory’s potential.

But, the way these pressurized containers are designed and manufactured haven’t changed much through years. This is primarily because the way pressure vessel fails has remained the same.

To keep safety as paramount, design engineers and manufacturers for pressure vessels follow ASME guidelines, and even extend to attain a certification stamp to reflect their commitment to quality and safety.

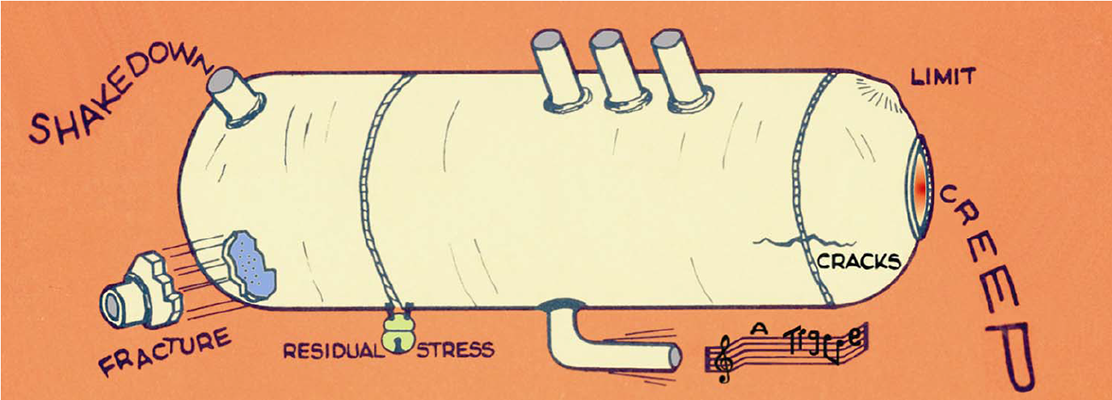

Source: 1973 Strathclyde training course leaflet

While these codes do a good job and has evolved substantially over many years, the use of these standard guidelines often leads to a pressure vessel design that’s conservative and costly.

Without a doubt though, these codes have helped to drastically reduce the number of deaths since its implementation, but it comes at a price with a design that’s overly utilizing the material. Looking at the present competitive landscape, this approach is indeed pricey.

It is no wonder why manufacturers have started adopting the use of alternative rules framed by ASME that permits the use of simulation tools to validate the design by analysis.

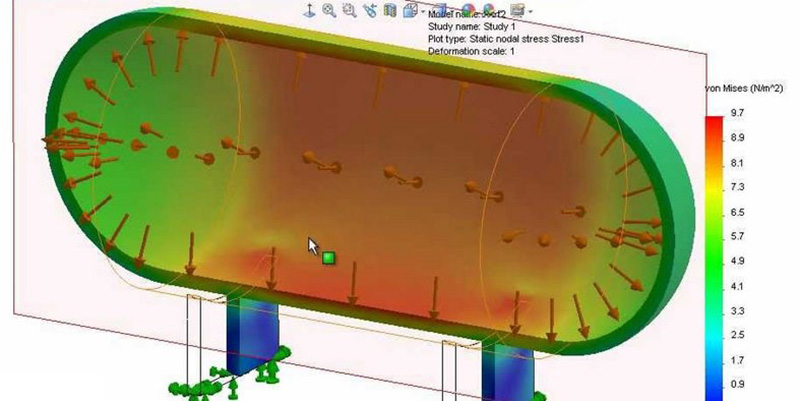

The Design by Analysis (DBA) was introduced later in Division 2 within the ASME BPVC Codes to allow better design, which optimizes manufacturing process and decreases production costs.

The Division 2 consists of more complex but accurate formulas and allows the design to obtain higher stress values, providing a room to reduce the material usage.

When comparing this alternative approach with the Design by Formula or the Division 1, there are lot of improvements in terms of optimizing the design, rather than relying on empirical relation that give out conservative design.

However, what makes the use of Div. 2 more profound is the ability to analyze complex pressure vessel designs. If you are simply creating a tank without any extremely angled nozzles or sharp transitions, design by formula works best.

But, with complicated geometries and loading conditions, you will need Div. 2 guidelines and perform the analysis using any industry standard program.

Piotr Stepien presented a detailed comparison of both the design methods i.e. Div.1 & Div.2 through simple calculations, pointing out how the FEA Elasto-Plastic Analysis is the most accurate and useful method to save material without compromising the PV design.

How reliable is the Design by Analysis method?

These rules have been developed by the ASME and fully comply with the standards; the same reflects in the Annex B.1 and C.1 as well which says,

“Design by analysis provides rules for the design of any component under any action. It may be used … as an alternative to design by formulas … as a compliment to design-by-formulas …”

What’s questionable however, is the judgment of the engineer in the application of these tools and their confidence in the program being used. For best practices, FE systems have to tightly integrate the interface between Codes of Practice and analysis.

Closure

While the Design by Formula is a robust and proven method, the design is often conservative. Moreover, the use of this method seems feasible only when the complexities in the geometry are few.

The Design by Analysis approach is certainly the need of an hour for pressure vessel manufacturers seeking to optimize the design and save some material and money.

This alternative approach as per ASME guidelines can be used as a compliment to design by formulas, and is not even cumbersome.

However, the results through analysis using FE systems are largely dependent on the user judgment, his proficiency with the FE tools and the reliability of the program being utilized.

Filed Under: Rapid prototyping