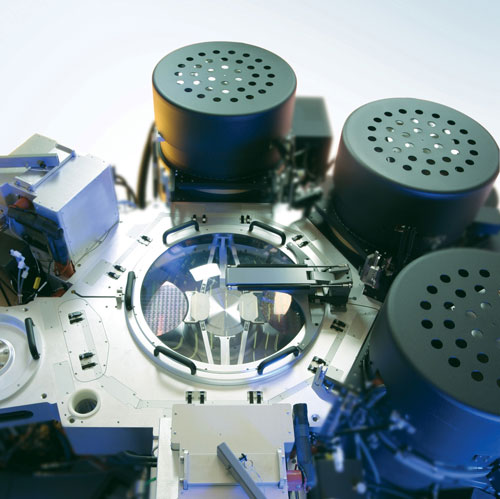

Applied Materials, Inc. (Nasdaq: AMAT) announced its new Applied Opus™ AdvantEdge™ Metal Etch, the industry’s fastest, most advanced system for etching sub-70nm aluminum interconnects in leading-edge Flash and DRAM memory devices. The system removes a critical etch bottleneck for customers by employing a process-optimized 5-chamber configuration (3 etch, 2 strip). Compared to standard 4-chamber metal etchers, the Opus AdvantEdge delivers 50% better critical dimension (CD) uniformity, a 2x faster strip rate with enhanced corrosion resistance, and 50% higher throughput — while still maintaining a standard etch bay footprint.

“The new Opus system combines our production-proven AdvantEdge technology with an optimized platform to deliver industry-leading on-wafer performance and productivity for metal etch, at approximately 20% lower cost of ownership,” said Tom St. Dennis, senior vice president and general manager of Applied Materials’ Etch, Cleans, Front End Products and Implant Group. “As the strong momentum of aluminum interconnects continues for Flash and DRAM applications, the Opus AdvantEdge system confirms Applied’s commitment to providing customers with the most advanced, cost-efficient etch technology to enable their current and future-generation device designs.”

Featuring proprietary wafer temperature tuning, a tunable RF source and specialized etch chemistry, the Applied Opus AdvantEdge metal etch system delivers <5nm, 3 sigma CD uniformity for aluminum interconnects. In addition to dramatically reducing strip time, the system’s Axiom™ strip chamber achieves more than twice the corrosion resistance of competitive systems.

Applied’s Metron division provides unique, pre-qualified abatement support for the Opus AdvantEdge system. A single Marathon 8600 system can reduce cost of ownership for etch customers by more than 50% over conventional abatement methods.

Applied has an installed base of over 60 AdvantEdge metal etch process chambers being used in production at Flash and DRAM customer fabs worldwide. To learn more about the Applied Opus AdvantEdge metal etch system, please visit: http://www.appliedmaterials.com/products/opus_advantedge_metal_etch.html

Applied Materials, Inc.

www.appliedmaterials.com

Filed Under: Semiconductor manufacture

Tell Us What You Think!