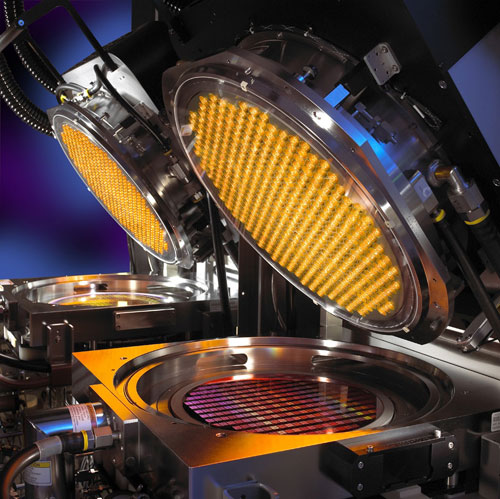

SANTA CLARA, Calif.–(BUSINESS WIRE)–Applied Materials, Inc. announces the shipment of its 250th Applied Vantage® RTP system, the rapid thermal processing (RTP) production system selected by every 300mm device manufacturer worldwide. The system’s innovative design has made it the most productive RTP system in the industry, achieving >90% availability and an unmatched mechanical throughput of >95 wafers per hour in a highly compact footprint. The Vantage’s chambers feature an optimized honeycomb lamp head for maximum heating efficiency and unique multi-point temperature sampling and control technology that ensures superior within-wafer and wafer-to-wafer uniformity.

“We thank our customers for working with us over the years in our drive to deliver best-in-class RTP performance,” said Tom St. Dennis, senior vice president and general manager of Applied Materials’ Etch, Cleans, Front End and Implant Groups. “As the next generation’s advanced transistors and memory cells require more tightly controlled thermal processing, customers can continue to rely on Applied Materials for advanced RTP technology to meet their most demanding manufacturing challenges.”

The Applied Vantage is the most flexible thermal processing platform on the market, addressing all spike, soak, contact and silicide anneals, thermal nitridation, and both dry and radical oxidation. Available with the Applied RadiancePlus RTP or Applied RadOx RTP chambers, the system links two process chambers to an Applied factory interface and track robot to maximize productivity per square foot. The entire system ships as one integrated unit, reducing fab install time to =10 days. Learn more about the Applied Vantage RTP system at www.appliedmaterials.com/vantagemilestone.

Applied Materials has more than 2,400 RTP chambers installed worldwide on its Vantage and Centura® platforms. According to VLSI Research, the RTP market is expected to grow at a compound annual rate of 12% from 2006-2011.

Applied Materials, Inc. (Nasdaq:AMAT) is the global leader in Nanomanufacturing Technology™ with a broad portfolio of innovative equipment, service and software products for the fabrication of semiconductor chips, flat panels, solar photovoltaic cells, flexible electronics and energy efficient glass. At Applied Materials, we apply Nanomanufacturing Technology to improve the way people live. Learn more at www.appliedmaterials.com.

Filed Under: Semiconductor manufacture

Tell Us What You Think!