Vepo Cheese outlined high performance, future-proofing, and an independent reject system on each line, as key criteria for its Oudewater factory in The Netherlands.

The North American cheese sector, valued at $56,976 million last year, is expected to grow annually by 2.1% CAGR between 2020-2023. Dutch imports of the dairy product make up a significant chunk of the market share, with statistics reporting a value of nearly $88 million last year.

For Vepo Cheese, which serves both national and international markets, the company recently chose Fortress Technology to upgrade its inspection process and introduce a more fail-safe solution for its growing production demands. The company outlined high performance, future-proofing, and an independent reject system on each line as key criteria for its Oudewater factory in The Netherlands.

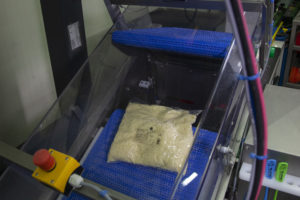

Approaching Dutch manufacturer Jansen Control Systems to design the compact incline inspection lines, each integrated with a vertical packaging machine, Vepo first examined Fortress’ Stealth system. However, the company soon realized the increased sensitivity of the Fortress Interceptor metal detector and the advantages it could bring for cheese applications.

Cheese comes in many forms and has high conductivity, so it is one of the most challenging products for metal detection. Explaining the issue, Fortress Regional Sales Manager Eric Garr comments, “Inspecting wet products has for many years presented cheesemakers with several challenges. Due to the high moisture content, combined with minerals and salt, cheese, like metal, can be very conductive — resulting in a high level of product effect. Also, in many cases, the product effect of cheese may lack a specific phase point as it moves through the aperture of a metal detector, adding to the challenge of overcoming the product effect.”

The Interceptor overcomes the propensity of “wet” product effects that can drown out the signal, particularly signals caused by a stainless-steel contaminant. Software algorithms make this possible by distinguishing between indicators specific to the product and those that flag anomalies.

The Interceptor overcomes the propensity of “wet” product effects that can drown out the signal, particularly signals caused by a stainless-steel contaminant. Software algorithms make this possible by distinguishing between indicators specific to the product and those that flag anomalies. By singling out low-frequency signals, the Interceptor leaves the alert from stainless steel more readily identifiable in the higher-frequency range.

The result of separating these two readings is that any genuine contamination from metal is not swamped by product effect.

The ability to isolate rejected packs without interrupting the production flow was also crucial to Vepo. On previous inspection lines, the company did not have an automated reject system. If a contaminated pack was identified, the belt would stop, and an operative would have to intervene, remove the pack, and restart the inspection process. This business interruption impacted productivity.

Reaffirming the importance of automation efficiency, Technical Operations Manager at Vepo, Hugo van Put said, “The automated reject system gives us 100% control overproduction. There’s less human involvement, therefore less risk of human error. This also lowers the risk of a metal contaminant slipping through the safety net. From an efficiency perspective, continuous production is one of the main benefits.”

The ability to isolate rejected packs without interrupting the production flow was also crucial to Vepo. On previous inspection lines, the company did not have an automated reject system. If a contaminated pack was identified, the belt would stop, and an operative would have to intervene.

Noting that the one-day installation went smoothly with clear training support, Hugo adds that false-positive rejects have also fallen since the systems were implemented. “Fortress metal detectors are really sensitive. This helps us feel confident that the risks of contaminants are minimal, with less chance of a food safety issue. Having the double readings within the Interceptor system also lowers the risk of false-positive rejects, which saves on food waste.”

Processing transparency is another advantage of the fully integrated packing system. Each metal detector has Contact Reporter software. Data from each packaging line is collated in a universal collection system, enabling quality assurance and production leaders to monitor processing and inspection performance from a centralized location. This automated record keeper developed by Fortress also helps the factory to keep track of and record data for rejects, tests, and process settings. Therefore, the cost of maintenance and spare parts is lower.

Commenting on the installation, which went live in August 2019, Hugo concluded, “Efficiency is integral to our production process. And the two teams understand exactly where we are coming from in terms of balancing product quality and enhancing operational productivity.”

Fortress Technology

fortresstechnology.com

Filed Under: Packaging