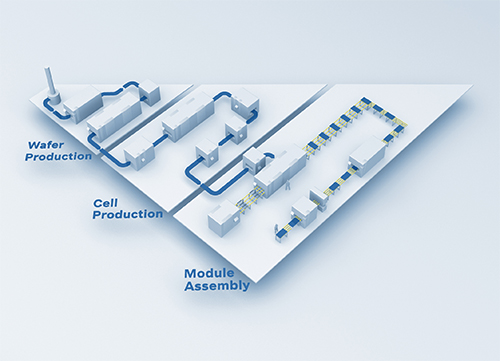

Hoffman Estates, IL – With additional modules, Rexroth expands the extensive automation kit for the photovoltaic industry. It covers all drive and control technologies for the entire production process from the ingot production to metallization, stringing, lay-up and flashing. In this connection, the kit enters new dimensions for increasing productivity with low production costs. The new vertical transfer for the Rexroth TSsolar assembly system bridges height differences from several hundred millimeters to several meters. Together with its camoLINE, the Cartesian Motion Building System with positive-locking connection technology, Rexroth opens up the possibility to replace the robots that have been used until now with Cartesian systems that offer considerably increased efficiency.

Continuous automation increases productivity: Rexroth solutions across the entire value-added process in photovoltaics

Using control technology that can be finely scaled in hardware and software, Rexroth considerably reduces complexity and allows for far-reaching standardization. Its drive-, controller- and PC-based Motion Logic integrations are continuously based on the open PLC according to IEC 61131. This standardizes the operation along the entire value-added chain and shortens the training and maintenance time. Rexroth IndraDrive servo drives with multi-Ethernet interface on hardware also simplify the spare parts logistics. In addition, Rexroth’s certified drive-integrated safety technology and condition monitoring system for electric drives and pneumatic cylinders considerably reduce the standstill times.

The Rexroth automation kit comprises controls, electric drives, pneumatic systems as well as linear motion and assembly technology compatible with each other. Rexroth, the only manufacturer of complete drive and control technologies, develops all these components aiming at the largest system capability. In this connection, Rexroth combines global application experience in the photovoltaic industry into one global industry management.

Bosch Rexroth AG

www.boschrexroth-us.com

::Design World::

Filed Under: Factory automation, Green engineering • renewable energy • sustainability, Motion control • motor controls, PLCs + PACs

Tell Us What You Think!