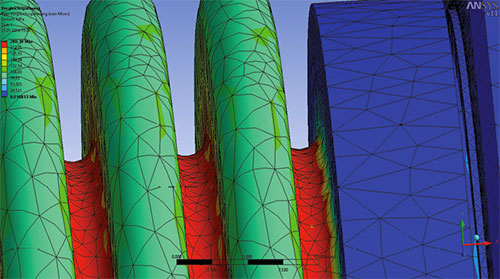

A metal bellows was evaluated using FEA. The specific loads in the corrugation valleys of the metal bellows are in red because of higher stress. This means that the corrugation valleys are the weak point of the metal bellows and most likely to break during an over torque situation, a common problem that should always be taken into consideration.

Tighten Up

“The most common mistake we have seen is when our customers do not tighten the clamping bolts to the recommended torque values. Rather than using a torque wrench, they estimate when the correct torque has been reached. In some cases, they do not tighten the clamping bolt enough and the coupling slips. On the other end of the spectrum, they over tighten the clamping bolt which can damage the bolt or even cause hub fracture.”

Clean up your act

“Another common mistake we see is when customers do not check to make sure the shafts and bores are cleaned and free from oil to prevent premature slippage.”

The Force is not with you

The Force is not with you

“The last mistake we see is often due to difficult assembly conditions (confined space) or tight shaft/hub tolerances; customers force the coupling onto the shaft, which compresses the bellows and can damage the coupling. To account for these scenarios, many couplings have the EASY clamp system which opens up the bore slightly to allow for easy installation without damage to the coupling or mating shafts.”

Out of sight, out of mind

One of the worst coupling installations I’ve seen was for an application where the parallel misalignment between shafts was actually visible. Normally it takes a precision gauge to measure the misalignment as we are generally talking distances of 0.3 mm (0.0118 in.). So being able to visually observe the misalignment gave us a clear diagnosis.”

We also had some questions for Parzych about couplings when your design will likely experience large loads. Here is what he had to say:

“When expecting large loads for a motion system design, a few things need to be considered in addition to the usual. First, the stakes are a bit higher; the amount of physical damage potential increases, and the cost of said damage compounds. With safety being the paramount concern for any engineer, the increased forces of higher load designs need to be addressed early and often.

“The first step is to make sure the nominal torque rating of the coupling is greater than the peak torque of the application. While many couplings have a substantial safety factor built in, this methodology provides motion system designers with the confidence that couplings will do the job. It is always a good practice to be as comprehensive as possible when providing a manufacturer with the details that will determine a coupling’s necessary specifications. Oftentimes, manufacturers are provided with limited application information, and tend to be conservative when sizing, especially for large load applications. Clearer application specifications helps puts the precise coupling in your design, as opposed to one that is simply ‘good enough.’”

GAM

www.gamweb.com

Filed Under: Couplings, MOTION CONTROL

Tell Us What You Think!