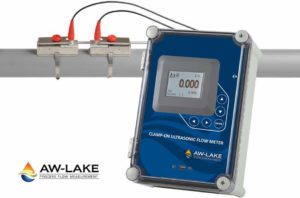

AW-Lake introduces a new series of Clamp-On Ultrasonic Flow Meters that fasten on the outside of vertical or horizontal pipes ranging in size from ½ in. through 48 in. Housed in a water and dust-tight NEMA 4X polycarbonate enclosure, the Clamp-On Ultrasonic Flow Meters are compatible with a range of metal and plastic pipe materials and “difficult liquids” such as chemicals, viscous liquids and abrasives that would damage standard flow meters. As a result, the non-intrusive, clamp-on ultrasonic sensors feature enhanced flow measurement with no pressure drop in a range of applications such as food or chemical processing plants, oil refineries and more.

Operating from 100 – 240 Vac, the Clamp-On Ultrasonic Flow Meters offer an isolated 4-20 mA output that can transmit flow readings to remote displays, recorders or controllers. The programmable relays are useable for flow control, pump protection or flow proportional pulse. A built-in keypad and simple menu system simplify calibration and programming of pipe diameter, pipe material, liquid types and measurement units. Users can choose to display and totalize flow readings in preferred volumetric engineering units including gallons and liters.

A 128 MB data logger is standard, capable of capturing up to 26 million data points. Optional MODBUS RTU via RS-485 or HART communication protocols are available for connection to automation systems that enables users to receive instantaneous flow rate, volume and total, run hours and diagnostic information. In addition to being password protected, AW-Lake’s new Ultrasonic Flow Meters retain all settings, values and totals in cases of power interruptions.

How It Works

In operation, the Clamp-On Ultrasonic Flow Meters utilize the “different transit time” ultrasonic principle of measurement to measure flow from the outside of pipes by calculating the time of flight difference for ultrasonic sound pulses transmitted between two sensors that are placed on the measuring tube. Each sensor can alternately transmit and receive ultrasonic signals, while simultaneously measuring the signal transit time.

As soon as the fluid in the tube starts to flow, the signals are accelerated in the direction of flow, but delayed in the opposite direction. By comparing these differences with precision timing circuits, the Ultrasonic Flow meter can accurately calculate the flow rate.

Designed to operate at temperatures of -40° F to 300° F (-40° C to 150° C), the Clamp-On Ultrasonic Flow Meters offer a measurement accuracy of ±1.0% of reading from 1.5 to 40 ft/sec (0.5 to 12.0 m/sec) and ±0.015 ft/sec (±0.0046 m/sec) for velocity below 1.5 ft/sec (0.46 m/sec).

For more information on the Clamp-On Ultrasonic Flow Meters, download the datasheets here

AW-Lake Company

You may also like:

Filed Under: TEST & MEASUREMENT