By Roger Altendorf, Photoelectric Product Specialist, Balluff, Inc. Florence, Ky.

Can photoelectric sensors detect a target six feet away? Traditionally, this would be extremely difficult, but new background-suppression sensors can do it – easily.

False triggers caused by shiny background surfaces are now eliminated with new background-suppression technology used in traditional, diffuse photoelectric sensors.

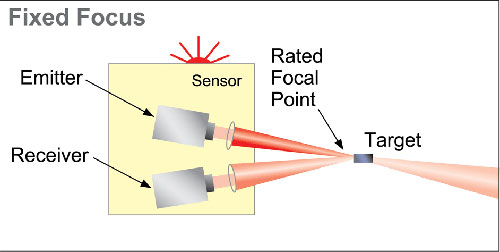

At first, some manufacturers made diffuse sensors with a fixed focal point by rotating the emitter and receiver within the sensor housing. However, a major drawback was found in the mounting position that often did not let the sensor capture the target in its focal-point area.

The shape of the triangle depends on the location of the target, so the receiver can detect changes that separate the target from objects in the background.

What are background-suppression sensors? In simple terms, they are photoelectric sensors designed to detect a specific target reliably while ignoring objects or surfaces in the background. Two simple examples of this concept include observing the head of a screw while ignoring the material it fastens to, and seeing a component mounted to a circuit board while masking the circuit board itself.

The development of background-suppression technology came out of efforts in trying to solve the problem of using traditional diffuse photoelectric sensors when shiny surfaces in the background caused false triggers. In first attempts, many sensor manufacturers turned to producing diffuse sensors with a fixed focal point by rotating the emitter and receiver within the sensor housing. A major drawback of these so-called “fixed-focus” sensors is that they cannot guarantee to capture every target in their focal-point area. This makes sensor mounting difficult, or it could require a unique sensor for a particular range.

Not satisfied with these results, designers developed several types of background-suppression architectures based on the principle of triangulation. Triangulation refers to the path that the light travels from the emitter to the target and back again to the receiver. Based on the location of the target and changes in the dimensions of the triangle, the receiver can distinguish the target from objects in the background.

Three types

The three main types of background-suppression sensors currently available are called sharp cutoff, mechanically adjustable, and electronically adjustable. The name of the first type, sharp cutoff, means that the sensing field or the distance between the sensor and the target is not adjustable. It works better than a standard fixed-focus, diffuse sensor because it contains multiple receivers that pick up light in a much larger sensing field.

For applications that require detecting a target at a long range, sensors that have a larger separation between the emitter and the receiver are necessary. The sensor on the left is smaller, which is the limiting factor of its sensing range.

Size, performance, and range

Additional problems with background-suppression sensors include tradeoffs between sensing distance and resolution. Typically, the resolution is inversely proportional to the target distance. This is mainly due to the level of precision and filtering that can be built into the receiving elements and the amount of light that enters through the larger receiving lenses.

Bigger, better, faster applications

Long-range, background-suppression sensors are the best choice for detecting large objects or for applications where mounting restrictions require that the sensors be located a specific distance from the manufacturing process. Here are two examples:

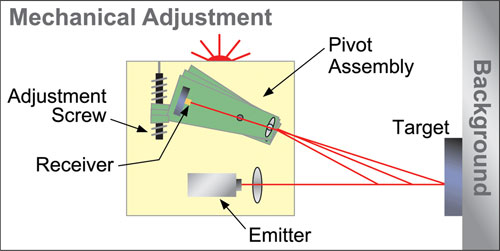

Another sensor type is mechanically adjustable. This type of background suppression sensor contains a potentiometer mechanically linked to the receiver assembly. The potentiometer adjustment changes the angle of the receiver with respect to its lens and the set point at which the reflected light from the target turns on the sensors’ output.

The last method available for background suppression is electronic adjustment. In this method, the set point on the PSD (position-sensitive device) can be programmed to let the output of the sensor turn on when the light returning from the target reaches the exact position. A pushbutton typically programs the set point.

Are long-range sensors right for you?

Large objects, unique mounting restrictions, and challenging process environments have often prevented some from using background-suppression sensors. However, as products continue to emerge with new features such as sensing ranges of two meters or longer and the ability to ignore shiny backgrounds, they will make more state-of-the art sensors available to solve long-range applications.

Long-range, background-suppression sensors verify the position of a car assembly. This speeds the assembly process and improves the quality of the final product.

Balluff

www.balluff.com/50k

Filed Under: SENSORS, TEST & MEASUREMENT

Tell Us What You Think!