Medical device engineers are evaluating the use of tiny springs to improve the performance of implantable devices that act like joints in the human body.

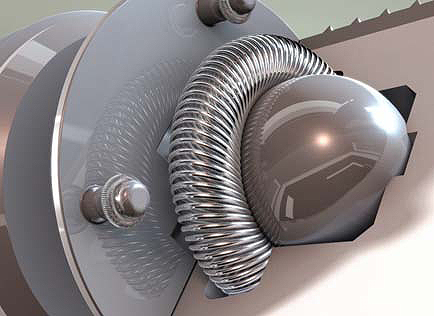

The springs, manufactured by Bal Seal Engineering, Inc., have been incorporated into the conceptual design of a ball-and-socket type carpometacarpal (CMC) device used to replace diseased or arthritic joints and restore movement. According to Bal Seal, the medical-grade titanium springs can ensure smooth rotary motion in the application, and their retaining capabilities have the potential to greatly minimize the possibility of dislocation.

The CMC joint device design concept hasn’t been clinically tested and approved for use in arthroplasty operations yet. But for its creator, Bal Seal Medical Applications Engineer Sean Madanipour, that wasn’t the goal. He wanted to illustrate how his company’s unique spring technology can help medical OEMs enhance the performance of new and existing orthopedic devices without dramatically affecting design requirements or cost.

In Madanipour’s design, the Bal Seal spring pre-loads the ball in a socket lined with ultrahigh molecular weight polyethylene (UHMWPE). Smaller springs affixed to pins are used to retain plates that restrict the movement of the assembly to two axes, in order to mimic the saddle-shaped joint’s native motion.

According to the engineer, the coil gauge and density of Bal Seal’s springs can be precisely engineered to handle a wide variety of force ranges, and the consistent contact of their coils ensures smooth, homogenous rotation.

To view an animated sequence featuring the CMC joint concept (as well as examples of connecting and sealing solutions in ultrasound transducer and insulin pump applications), visit the company’s online mediaroom at http://mediaroom.balseal.com/vod.

Filed Under: Medical-device manufacture, FASTENING • JOINING • locks • latches • pins, Springs • wave springs

Tell Us What You Think!