Ventilator management is paramount to intensive care, but clinical training may not provide medical students with adequate experience in this area. Hands-on work in adjusting the ventilator to changing patient parameters in real time is invaluable to understanding the process.

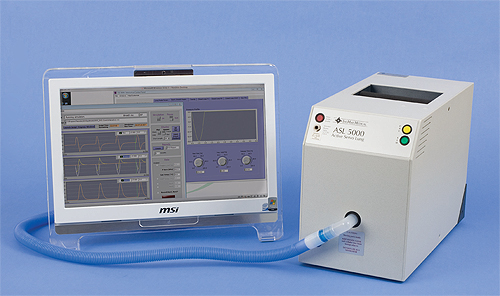

To aid medical educational programs, Stefan Frembgen, president, IngMar Medical, a company that specializes in the design and development of respiratory simulation devices, designed the ASL 5000 Breathing Simulator. This easily operated device helps medical students simulate disease states with a few mouse clicks.

Digitally controlled, the ASL 5000 can simulate real life respiratory scenarios from neonatal to adult patients, including coughs, apnea, active exhalation—even snoring. A unique feature of the device is its ability to breathe spontaneously while being ventilated.

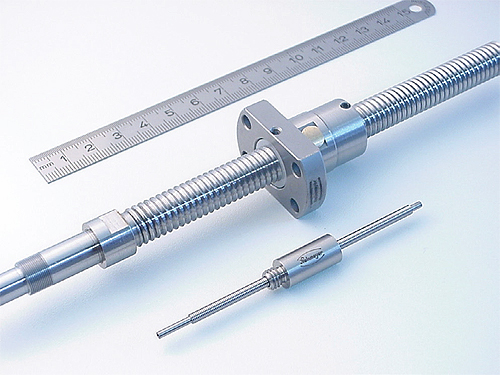

Ball screws, similar to these, are used in the breathing simulator.

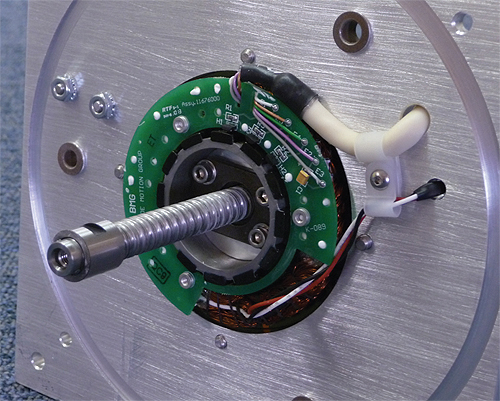

A brushless dc motor and encoder gives the user total positioning accuracy. Also inside the unit, a cylinder moves a piston plate back and forth, which simulates moving air in and out of one or two lungs. Attached to the piston plate is a ball screw, manufactured by Steinmeyer. When activated, the ball screw must move varying distances. A controller updates its position every ½ millisecond to simulate various breathing disorders. The unit must be a very dynamic system to respond to other inputs, such as ventilators and human patient simulators.

The ASL 5000 is a digitally controlled breathing simulator that can simulate real life respiratory scenarios from neonatal to adult patients, including coughs, apnea, active exhalation—even snoring.

Frembgen, who designed the simulator, noted that he chose a spinning ball nut design because he wanted the ability to control the precision movement—but with a component that was at a reasonable cost. “We want hard control over how we move air,” he said.

A ball screw was the best solution for this requirement. When reacting to various breathing conditions, the ball screw must accelerate quickly, often within milliseconds, to move at momentary speeds of 3000 rpm. Frembgen chose a moving ball nut design so that the screw shaft can move the piston plate. The ability of the device to react so quickly is why it can follow specific movements of human patient simulators.

Some common breathing states are programmed into the simulator. But users can create their own unique scenarios, such as COPD and Asthma, for the full range of adult, pediatric, and neonatal patient models.

A rotating nut ball screw attached to a piston plate and cylinder unit delivers hard control of air movement.

The simulator captures more than 50 parameters, to provide hours of trending and review as well as real-time analysis.

Steinmeyer Inc.

www.steinmeyer.com

IngMar Medical

www.ingmarmed.com

::Design World::

Filed Under: Ballscrews • leadscrews, Medical-device manufacture, Fighting COVID-19, MECHANICAL POWER TRANSMISSION, Motion control • motor controls

Tell Us What You Think!