The development of bearings for renewable energy concepts presents both interesting opportunities and exacting challenges. For example, tidal current turbines are among the latest developments in renewable energy use. Installed undersea, the turbines are driven by the tidal flow of water. Bearing manufacturer NKE Austria supplies the bearings for the gearboxes of these “underwater windmills.”

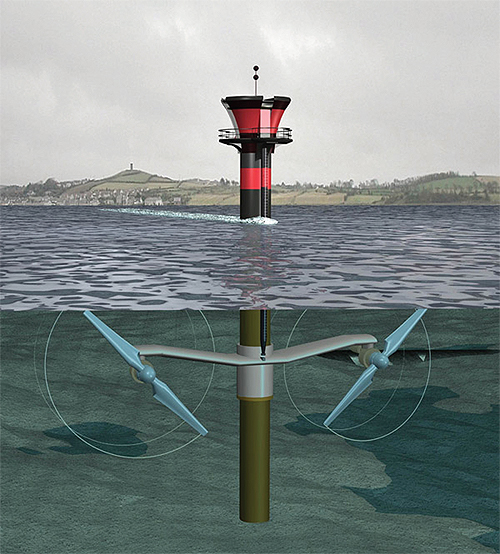

The SeaGen tidal current turbine, developed by Marine Current Turbines Ltd. (MCT), Bristol, United Kingdom, is rated at 1.2 MW. The turbine works much like an “underwater wind turbine” but is driven by the tidal current rather than air.

The SeaGen tidal current turbine was developed by tidal turbines technology leader Marine Current Turbines Ltd. (MCT) based in Bristol, United Kingdom. Rated at 1.2 MW the turbine works much like an “underwater wind turbine,” but is driven by the tidal current rather than air. Unlike wind energy, which is subject to the random nature of the weather, tidal flows are more predictable. Moreover, due to the higher density of water compared to air, underwater turbines do not need to be as large as wind turbines. SeaGen has been installed in Northern Ireland’s Strangford Lough and is the world’s first commercially operated tidal current turbine.

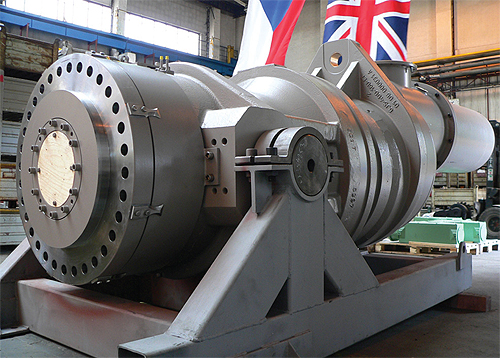

The SeaGen turbine’s gearbox, designed by Orbital2 Ltd., a British specialist for renewable energy gearboxes, and made by wind and industrial gearbox specialist Wikov MGI.

The SeaGen turbine’s gearbox was designed by Orbital2 Ltd., a British specialist for renewable energy gearboxes, and is made in the Czech Republic by wind and industrial gearbox specialist Wikov MGI. The gearbox developers and manufacturers selected NKE Austria to supply the bearings; the company supplied nine different types of bearings for the gearboxes, including deep groove ball bearings, tapered roller bearings, cylindrical roller bearings and four-point contact ball bearings, with outer diameters from 300 to 1090 mm.

NKE Austria GmbH

www.nke.at

Filed Under: Bearings, Energy management + harvesting, Gears • gearheads • speed reducers

Tell Us What You Think!