Recently, I attended the Milwaukee Tools New Product Symposium (NPS) 2018, and was able to witness many new tools in action. Although, I chickened out on actually using the tools, I foraged forward among the sawdust, fog machines and electric sparks to take some neat pictures and learn behind-the-scenes product design secrets and new upcoming industry trends.

Sparks fly as Milwaukee Tool’s employee demonstrates sawing through a hunk of thick, pipe metal.

At the event, Milwaukee Tools announced nine new products they redesigned with different technology and breakthrough solutions:

- 1-inch High Torque Impact Wrench with One-Key

- Drill/Driver and Hammer Drill

- Hex Impact Driver

- 7-1/4-inch Circular Saw

- Wireless Table Saw with One-Key

- 7-inch and 9-inch Large Angle Grinder

- Super Sawzall Recip Saw

- Chainsaw

- RedLithium High Output HD12.0 Battery

The nine new tools of 2018 were featured in a dramatic setting at the Milwaukee Tools NPS2018

I’ll dial in on just a few of the newest product designs. First, let’s turn our attention to batteries, which are the core to many of these wireless products.

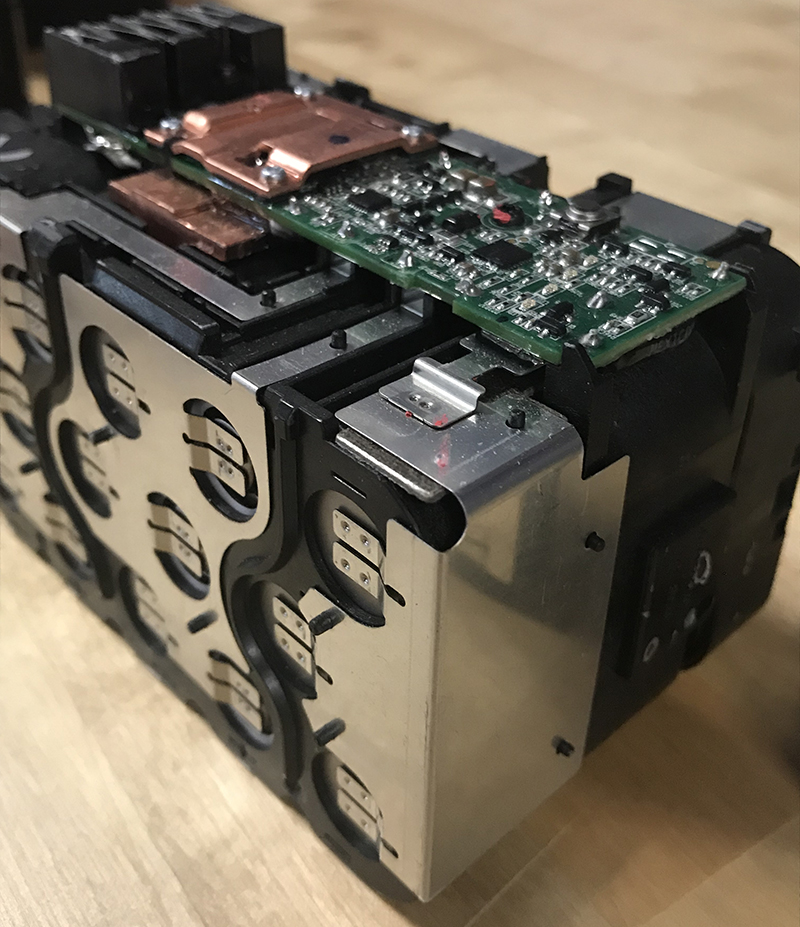

M18 RedLithium High Output HD 12.0 Battery

These batteries were redesigned with two breakthroughs in technology. First, the new cell of the battery is 21mm by 70.0mm, while before it was 18mm by 65.0mm. With the volume increase and extra space they were able to advance the chemistry and mechanical design to make it more powerful. The second concept was to overhaul the electronic pack. The cells could generate more power, so they reengineered the power to the battery to get all of the power out to the tool in use. Additionally, this process allowed them to advance the intelligence and communication going out to the products and drive system compatibility.

This redesign allows the battery to run cooler and not overheat. It also has the capacity to work in -20 degree Fahrenheit temperatures. To test this theory, they left the tools in a temperature chamber, pulled them out and ran the tools immediately after being exposed to freezing temperatures. They ran just fine.

Lastly, to my surprise, one charge lasts between 75 and 80 windows being framed. The upgraded electronics in these batteries are going to take advantage of a new charger that is in development to launch next year. This will supposedly have the fastest charge rates delivered in a cordless system, but we’ll have to wait and see!

Milwaukee Tools redesigned their RedLithium High Output HD battery

One-Key App

Next, there is a new application that can actually keep track of tools for construction sites. A neat solution to tools being stolen on-site is Milwaukee Tool’s One-Key app with which users can track, manage and secure their tools. By pressing a button on the app, users can lock up their tools and ensure no one can turn them on. Even if the person stealing and using the tool has their own Milwaukee Tool battery to plug into the device, it won’t work. People can also track their tools, so, if it is lost or stolen, One Key will track the tool from the last place it came in contact with the app. This can provide possible information about its whereabouts. This app also tracks the serial number from your receipt, so all the information is stored within the app.

The One-Key app helps keep tools from getting stolen or lost.

Wireless Table Saw

You heard it right! There is now a wireless table saw. This device uses a POWERSTATE brushless motor to help with power and performance. The incorporated REDLINK PLUS intelligence helps with overload protection and prevents damage to the tool and battery. Its rack and pinion fence system ensures it can quickly adjust and make more accurate cuts. Despite being wireless, it has the capability to perform 600 linear feet of cutting, but if you do run out of juice you can always use the m18 battery.

All people attending the show could use any of the tools exhibited. Here one of the attendees is using the wireless saw.

Hex Impact Driver

Milwaukee Tools implemented a new process with this tool to pull more current and energy from their packs. By delivering power to the motor, the motor gives more torque and is also a quarter inch smaller. Because it is smaller, they invested in a new technology and used precision winding machines in the assembly process. This method helps wind and pack the copper tighter than ever before, so the tool has more power in the pack. They also inserted a molded rotor impact and took an inch out by incorporating the motor in the actual back half of the tool.

Many of the trades that utilize this tool do self-tapping screws, so the physical design of this tool was intended for a one-handed use. Lastly, the electronical engineers redesigned the algorithyms and updated the software, so when the device is not intended for use, you can still have your finger on the trigger but it will be completely shut off.

Milwaukee Tool employee explains how the hex impact driver has been redesigned during a station workshop

Design Process

One of the neat aspects of Milwaukee Tool’s design process is the research that goes into each product. For each tool, they physically talk to industrial experts and people who utilize these tools every day to customize and create a product that is better engineered for specific uses.

Additionally, they undergo thorough research for their new prototypes. They conduct ergonomics analysis with decibel monitoring, postural analysis, and muscle effort and fatigue biofeedback. I witnessed one employee with a wearable sensor connected to a computer. He had three electrodes on his arm that monitored the main primary muscles to pop a rivet. He used two different tools, which gave feedback on what tool required more extraneous effort. This in turn, helps Milwaukee Tools develop products that ensure longer user ability, less exertion of muscles and promote fewer injuries. They also use a vibration test to see how much vibration goes into the body, and with the information provided they are able to turn the results into health metrics to better design their products.

This summer, they are introducing a field guide on utility ergonomics that will be designed for utility trucks across the country. It will provide information about muscle fatigue in common tools, updates on injury statistics, stretching and warm-up recommendations, and how to maintain strength and health throughout a career.

Milwaukee Tool employee has three separate sensors wrapped around his arm and watches as his muscle effort metrics project onto a computer screen.

Upcoming Industry Designs

There are a ton of upcoming products and designs I got to see for the lighting realm, mechanical plumbing, power utility, carpentry, drilling and fastening, hand tools storage and electrical.

Tools many of us have used are tape measures and levels. Milwaukee tools has designed digital levels that use pinpoint measurement technology, so you never have to calibrate them. There is actually a multi-point calibration process that is done before the product is bought.

Examples of the different digital levels

The STUD tape measure uses EXO360 blade technology to protect it from ripping. The tape measure has an exoskeleton that is equipped with an impact-resistant overmold. We saw the tape measure drop from the top of a building with no harm done. We also watched as an employee expanded the tape measure, bent it and stepped on it with a cement block, and nothing ripped or tore.

Demonstration of the STUD tape measure

Additionally, here are a few of the tools launching at the end of 2018:

- Lineman’s Hawkbill Knives with Utility Ring

- Power Utility Storage

- Shockwave Impact Duty Step Bits

- PACKOUT Modular Storage Expansion

- Magnetic Tape Measures

- M18 Fuel 3-in-1 Backpack Vacuum

- M18 Fuel D-Handle Jig Saw

- USB Rechargeable ROVER Pivoting Flood Light

- WORKSKIN Cold Weather Balacava and Hardhat Liner

- Extreme Metal-Cutting Band Saw Blades

This is a just a glimpse of everything I saw at Milwaukee Tools NSP2018, but they said this isn’t anything compared to what’s coming next year, but we’ll have to see for ourselves!

If you want to do more ‘drilling’ and digging you can visit the Milwaukee Tools website!

Filed Under: Rapid prototyping