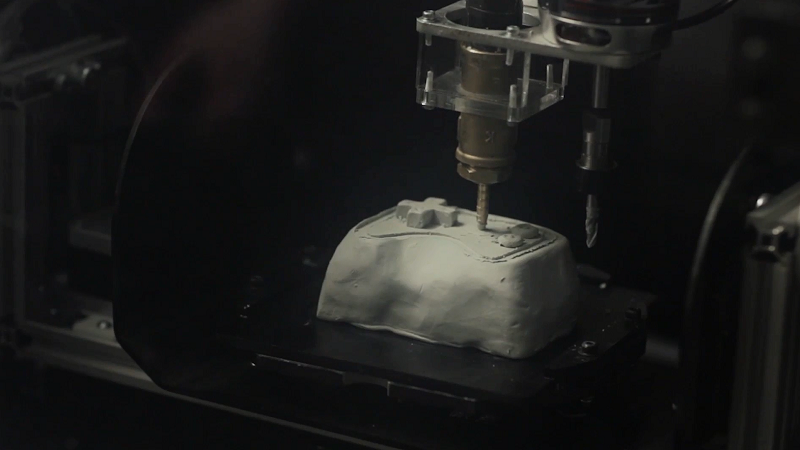

The researchers at Lancaster University used the ReForm machine to fabricate a console game controller. Image credit: University of Lancaster

Researchers at Lancaster University have developed a new hybrid form of fabrication that combines digital 3D modeling and physical building.

Called the ReForm, the machine scans physical objects and then builds them using a custom-built 3D printer that extrudes clay. Changes can be made to the clay model and then scanned to put the digital model of the item back into the printer, which can then make its own further changes to the model.

The machine can also re-sculpt the clay product if it is dropped or if the human designer makes a mistake. It can use either additive or subtractive manufacturing to do this. The resulting product will be a sort of collaboration between a human designer and the ReForm machine.

“Before you had to be an expert in computer aided design. ReForm means you no longer have to be a technical expert to design objects for 3D printing. People can get hands-on and iteratively and inexpensively design objects in a much more efficient way,” said Jason Alexander, a lecturer in human-computer interaction at Lancaster and the lead on the project. “We will find that people will be able to create artefacts for 3D printing that are a lot more creative and fit for purpose.”

The device, created at Lancaster’s School of Computing and Communications, should be able to leverage the talents of both human and machine, its creators said in a press release. Designers can detail a device and shape it according to their ideas, while the printer can be used to create precise holes and straight, flat surfaces.

A stylus pen can be used to draw on the surface of the model. The machine can then use this as a guideline to drill, draw, or print along.

So far, the team at Lancaster has used ReForm to create a smartwatch strap, a console game controller, a key hook, and a smartphone docking station.

Filed Under: 3D printing • additive • stereolithography, Industrial automation