Energy-efficient gripping principles found in nature can be applied to automation technology and deliver small, lightweight, and powerful grippers. While gripping, holding,and setting down objects are vital production processes, conventional grippers are not always energy efficient when it comes to their gripping force-to-weight ratio. Nature, on the other hand, abounds with perfect examples of principles of efficiency. With the NanoForceGripper, engineers from the Festo Bionic Learning Network have developed a gripper whose suction cup-like components are modeled on the pads of a gecko. NanoForceGrippers cling reliably and permanently to the surfaces of the object to be gripped thanks to the tiny, intermolecular van der Waals forces. A key component of the gripper is the Gecko® Nanoplast® tape on its underside with 29,000 gripping elements per cm².

The NanoForceGripper grip is based on tiny, intermolecular van der Waals forces that work with Gecko® Nanoplast® tape.

Once a part is gripped, it is permanently held by the gripper without the need for energy. A counteracting force is all that is needed to release the bond and set down the gripped object. The tape is peeled off by means of a structure with Fin Ray Effect®, which is modeled on the tail fin of a fish. The spring forces are released by a push-push mechanism that deforms the structure from a straight surface to a curved one. The effective holding surface covered by the tape becomes increasingly smaller until the gripped object is released gently. Energy-free holding and energy-efficient gripping are an innovation for grippers that work with a push-push mechanism. This type of energy-free holding of objects was not previously possible.

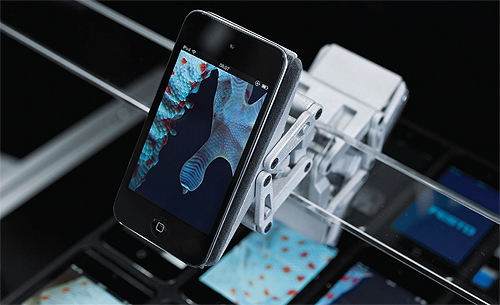

The NanoForceGripper can grip especially delicate objects with smooth surface such as glasses or displays with little energy. The technology complements the existing pneumatic gripping technology and can be used as needed to the application.

The PowerGripper uses the Watt’s linkage principle with the Festo fluidic muscle to deliver a strong grip that is delicate enough to hold fragile objects.

The PowerGripper is a university project developed within the framework of the Bionic Learning Network. It is modeled on the complex kinematics of a bird’s beak. The motion principle employed is Watt’s linkage. The developers of the gripping system used the fluidic muscle from Festo to create the bionic principle, combining it with the production process of metal laser melting. This gripper has a good force to weight ratio thanks to the lightweight construction, the lightweight pneumatic muscles and the use of a titanium alloy (Ti6Al-4V) as the material for the basic components. As a research project, the PowerGripper demonstrates numerous possibilities for the development of new gripping systems. The lightweight yet very stable structure of the gripper means that the entire system behind it can also be lightweight and as a result operated with greater energy efficiency.

Festo Corp.

www.festo.com/us

Filed Under: Factory automation, The Robot Report, Motion control • motor controls, Mechatronics

Tell Us What You Think!