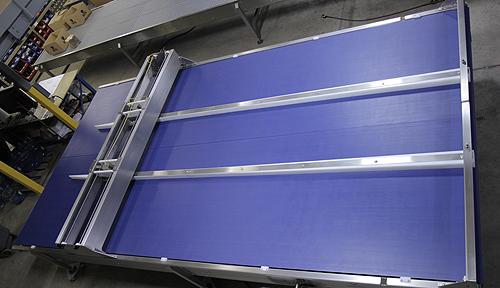

Eaglestone is a custom conveyor and equipment manufacturer specializing in solutions that are safe for food processing and packaging. Designed to not only reduce accumulation of foodborne bacteria but also to improve productivity with reduced need for cleaning and maintenance, Eaglestone’s equipment has been integrated into a multitude of different food processing applications. Recently, they collaborated with Apex Industrial Automation and Bison Gear and Engineering on a new stainless steel product conveyor used to transfer baked and frozen goods down the production line. Bison was able to recommend a newly designed stainless steel gear motor that would provide long-lasting operation while maintaining a clean and bacteria-free environment.

To drive the operation of their conveyor that would separate the frozen goods into two production lines, Eaglestone required a gear motor that would support a clean environment and be able to withstand IP69K rated wash-down processes – high temperatures and high pressure cleaning. Eaglestone was also seeking a compact motor to reduce bulky components and weight on the conveyor. Other important design criteria for the gear motor included a completely enclosed system to prevent ingress of contaminants and a smooth outer surface without crevices to further reduce bacteria growth.

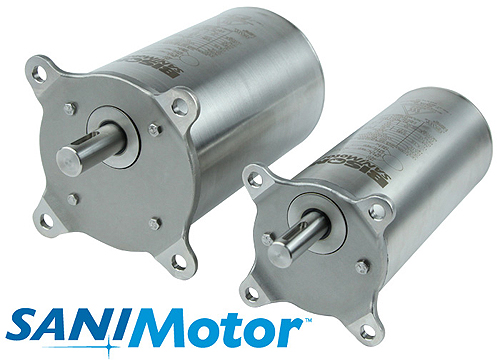

After reviewing the design specifications and working with Bison Gear’s application engineers, Eaglestone selected their new SANIMotor™ IP69K-rated gear motor. The SANIMotor™ features a smooth outer exterior encased in 304 grade stainless steel; ensuring clean, hygienic food processing while easily enduring moisture, heat and harsh cleaning solvents. To promote long product life and operation, the internal electrical components are encapsulated in epoxy resin to tolerate temperature extremes up to 40°C. Ideally suited for food service equipment, conveying, wash stations and chemical applications, the SANIMotor™ was a natural fit for Eaglestone’s conveyor.

Once installed, the SANIMotor™ performed very well in the harsh environment created by the wash-down process and provided reliable operation of the transfer conveyor without any maintenance issues. “Eaglestone builds heavy duty conveyors for high-volume, sanitary food applications,” states Carmen Sammauro, President of Eaglestone. “We chose the SANIMotor™ for its ability to stand up to the conditions of an extreme wash-down environment, and Bison exceeded our expectations.” Additionally, Sammauro mentioned that the SANIMotors™ delivered from Bison matched perfectly to the CAD dimensions supplied, and the product fit into the conveyor without issue. “We have had fitting issues with other motor manufacturers in the past, but the SANIMotors™ from Bison fit our application as designed.”

Bison Gear and Engineering

www.bisongear.com

::Design World::

Filed Under: Factory automation, Conveyors, LINEAR MOTION, MECHANICAL POWER TRANSMISSION, Gears • gearheads • speed reducers, Motion control • motor controls, Motors (gearmotors)

Tell Us What You Think!