As hospital budgets and insurance payouts shrink, medical device developers face smaller product development budgets. One area that is less threatened by the “economic scalpel,” however, is wireless technology. Thus, Bluetooth technology is becoming the favorite to increase the function, reliability and safety of various medical devices, including existing hard-wired applications.

Facilitating the entry of Bluetooth into the medical device industry is the modern protocol analyzer, now updated to effortlessly examine not only the wireless interface between devices, such as a glucose monitor and a Bluetooth-enabled telephone modem (used for wireless remote monitoring), but also the interface between the device CPU and the Bluetooth chip inside it.

Throughout the world, Bluetooth continues to grow in popularity, with an average of 85% of consumers aware of it, prompting ever more OEMs to take the wireless plunge. However, the need for wireless data recording and transmission reaches an almost acute level within the medical device industry.

“There are a sizeable percentage of chronic patients who are not capable of monitoring themselves, like a diabetic with nascent senile dementia,” observes Dr. Landau. His company, Polymap Wireless, develops and markets wireless systems and components for the remote monitoring of diabetes, congestive heart failure, hypertension, obesity, and other chronic conditions. “Even if they could, they wouldn’t know what to do with the numbers. These are the people who will derive a significant benefit from having a remote monitoring device watch over their numbers and relay the data to the proper healthcare professionals.”

Bluetooth is better than people think in terms of power consumption. For example, a wireless blood pressure cuff can take 600 measurements and transmit the data on only two AA batteries.

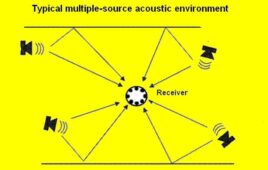

But Bluetooth is a complex technology with numerous protocols, profiles (use cases), and where the connection and disconnection of devices is almost always ad hoc. It is an ever-evolving standard, with a rapidly growing number of profiles and constant improvements and expansions in functions at the RF level. During the sending and receiving of information, any number of quality issues can arise including dropped connections, data corruption or loss, interference, slow throughput, and signal degradation.

Charlottesville, Virginia-based Frontline Test Equipment, Inc. is a leading provider of PC-based protocol analyzers for special-purpose data communication networks. For example, Frontline’s FTS4BT™ supports the new IEEE P11073-20601 Draft Standard for Health Informatics, Personal Health Device communication application profile and includes the Multi-Channel Adaptation Protocol.

Until recently, Bluetooth protocol analyzers could only operate by way of “air sniffing” the wireless link between devices, or by “Host Controller Interface (HCI) sniffing” the wired connection between the CPU and the Bluetooth chip inside the device. While examining each link individually provides valuable information, it does not go far enough. Fully featured protocol analyzers can air sniff and HCI sniff both sides of the Bluetooth chip simultaneously, enhancing the debugging and verification process.

Modern protocol analyzers go one step further by providing what is known as “virtual sniffing” where the analyzer does not physically tap the link. Virtual sniffing is an alternative to traditional HCI sniffing. Instead of a wired tap of the link between the CPU and the Bluetooth chip, virtual sniffing uses a software connection to supply the communication packets to the protocol analyzer. Since no probe is required to tap the link, equipment costs are lower. Virtual sniffing even simplifies the debugging process because oftentimes it is not convenient to physically tap the link.

Newer analyzers feature real-time displays to accelerate the debugging and verification process. The effect of these actions–whether “positive path” or regressive-are observed in real time on the analyzer screen. The test engineer no longer has to rely on notes or memory to reconstruct what took place when attempting to fix any problems.

The FTS4BT gives you a snapshot of what’s going on and, in an unequivocal way, provides documentation that proves that the device performs to design specifications.

Frontline Test Equipment, Inc.

www.fte.com

::Design World::

Filed Under: Wireless • 5G and more, Medical-device manufacture

Tell Us What You Think!