In booth #505, experience how Bosch Rexroth takes your assembly operations from start to finish with its complete portfolio of automation solutions. Start your journey towards a streamlined factory automation experience with Bosch Rexroth’s linear technology eTools portfolio, which makes it easier for users to plan, design and order Bosch Rexroth Linear Motion systems required for your line.

Then, experience a whole new world of joining technology and demo the latest addition to Bosch Rexroth’s tightening system portfolio, the Nexo generation 2 nutrunner featuring Rexroth’s Operator Guidance Software (OGS), which seamlessly integrates into conveying systems, aluminum framing workstations, and more. The next-generation Nexo is smaller, lighter, and even more powerful than the industry-leading Nexo.

Next, dive into our new automation technology featuring the ctrlX AUTOMATION system for packaging with our three-axis demo. This exhibit demonstrates how ctrlX drives and controls are smart, highly scalable, open and easily integrated into any automation infrastructure, while providing benefits such as reduced component and engineering costs by 30–50 percent.

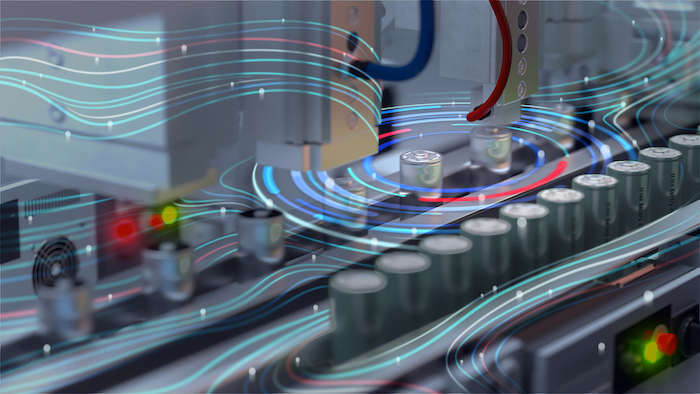

Advance down the line and experience the ActiveMover linear motor transfer system moving magnetic pallets with unprecedented speed and accuracy, providing key advantages to lower payload operations, such as battery cell transport. The free programming and control of each workpiece pallet allows adaptable realization of process flows and flexibility in changeovers and retooling processes. The system is integrated with the Smart Function Kit for Pressing, which simulates in-line testing of battery cells while product is on the ActiveMover.

Continue on your journey with a stop at the Smart Function Kit for Handling demonstration. This exhibit highlights features & benefits of the Smart Function Kit for Handling, combined with a working Cartesian multi-axis system whose configuration output can be created by booth visitors using adjacent Bosch Rexroth eTools software demonstration.

Move down the booth and watch the Flexible Transport System, powered by ctrlX CORE, enable transport of heavier payloads and positioning for various steps in demanding assembly applications like battery module transport. The Flexible Transport System demonstrates a complete factory automation solution, featuring products across Bosch Rexroth’s automation portfolio, including:

• TS2 conveyors

• ML3 synchronous linear motors with an iron core

• IndraControl YM

At the end of your journey, watch the MP1000R autonomous mobile robot transport assembled materials at the end of line from a workstation to a custom pallet rack, both assembled with various components from Bosch Rexroth’s aluminum framing portfolio.

For more information, visit www.boschrexroth-us.com/assemblyshow. The ASSEMBLY Show attendees are invited to visit booth #505 to learn more about how you can expand your productivity and give you the advantage you need to get to market faster.

Bosch Rexroth

www.boschrexroth-us.com

Filed Under: Factory automation, NEWS • PROFILES • EDITORIALS, Assembly