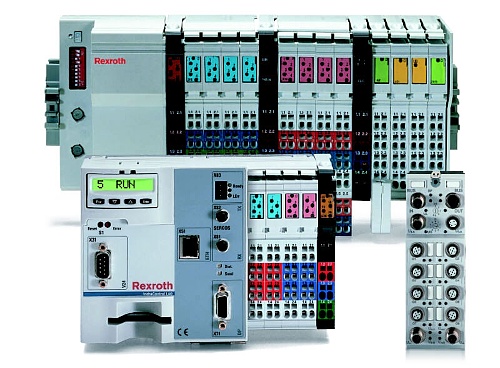

Hoffman Estates, IL ‚– Bosch Rexroth has added three new Inline I/O modules that reduce engineering time and cost while adding more functionality and versatility to the company‚’s family of scalable PLCs and PACs.

Ideal for motion-based machine builders and industrial OEMs in the printing, food and beverage, packaging, converting, woodworking, conveyor and general automation industries, the new modules can be used with any controller from the Rexroth line. All three modules help reduce engineering time, wiring and hardware costs, and are able to use the configuration software included in Rexroth‚’s IndraWorks integrated engineering and programming software suite.

The new I/O modules include the SSI and INC IN, which bring powerful encoder feedback capabilities to even smaller PLCs like the Rexroth L10, and the PWM/2 module for step and direction control or pulse width modulation.

SSI and INC Modules

The SSI and INC modules provide powerful encoder feedback capabilities for even the smaller, less expensive PLCs, such as Rexroth‚’s L10, giving machine builders the ability to build in simple motion control at a lower price point.

The SSI and INC can handle a large number of axes and can dictate position and speed. The SSI features four inputs and position detection which can identify the motor position during its rotation. The drive control allows the user to dictate position and speed of the drive. Priced lower, the INC encoder pulses quickly as the axis rotates. Based on a combination of signals that comes from the drives, the encoder module can identify the position of the motor in its rotation. The direction can be indicated with an INC encoder quadrature signal. It can execute precise control, allowing machine builders to incrementally fine tune the motor to specific degrees.

PWM/2 Module

The PWM/2 module provides pulse width modulation and step and direction control, giving machine builders more flexibility to alter the width of the pulse. This can be used to reduce the temperature of the drive and the amount of energy consumed. To help reduce operating costs, the step and direction aspect also allows the module to be used with stepper drives and motors, which are common in applications such as a pick-and-place and other positioning operations.

www.boschrexroth-us.com/inlineio

::Design World::

Filed Under: I/O modules, Motion control • motor controls, PLCs + PACs

Tell Us What You Think!