Engineers at Yale Lift Trucks recently redesigned its existing PK-35 braking system for its next-generation three-wheel truck series. They had to make the new trucks smaller and add a parking brake with a manual release.

Several different Yale and Hyster brake sit-down counterbalance trucks use the new PK-35 brake.

The company asked for help from Warner Electric. Mathieu Ruault, Warner Electric Forklift & Material Handling Market Manager said, “NACCO Materials Handling Group (NMHG) engineering requested design parameters including packaging, heat dissipation, and a special manual release. As a result, most of the brake components were newly designed to fit 100% to the customer’s requirement.” According to Matt Barrow, Yale Product Design Engineer, “Warner and NMHG engineers worked together to review the existing brake and how to improve it for the new required functions. The brake was examined for environmental resistance for added protection from debris and moisture, and we asked Warner to incorporate a manual override function that was easily accessible and mechanically driven.”

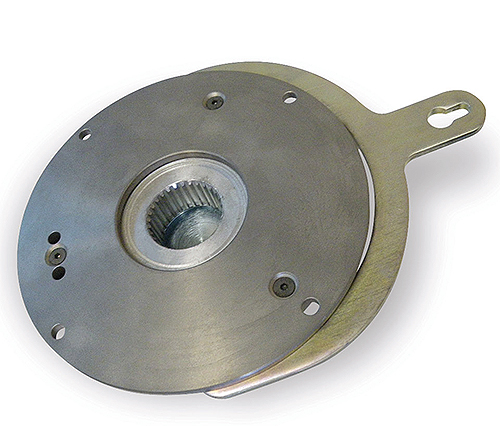

Various prototypes had to be made. Jeremy Raimbault, Warner design engineer, developed an improved version brake featuring an enclosed design, special manual release handle, a dual voltage coil, and a lower profile. The final design consisted of the features and benefits that NMHG needed.

The brake locks the traction motor shaft when the truck is parked. Springs push against a moving armature which clamps a friction disc on the motor shaft. When power is applied to the brake, an electromagnet pulls the moving armature and compresses the springs. The disc is then free to rotate and the truck can start moving.

The brake mounts on the back of the traction motors, on the opposite side of the gearbox. Two motors, sit back-to-back, and each is linked to the front wheels of the truck. “The brake needed to meet grade requirements,” said Barrow. “And it also needed to fit within a confined space on the end of the in-line traction motors. We were also looking for easy removal of the brake for servicing, without removing the drive unit or traction motor.”

The newly modified PK-35 brake is protected from debris and moisture and features a manual override function.

Warner and NMHG collaborated during the new brake testing including prototype units in the field. Warner ran lifecycle tests to simulate product life, air gap tests, and pull-in/holding tests. The testing determined the air gap limits and demonstrated that the brake would pull in to release as needed. It also determines how temperature affected pull-in responsiveness and timing. The lifecycle test simulated a fully loaded vehicle traveling at specific speeds to test dynamic braking capability and durability of the brake assembly.

The newly modified PK-35 brake is an integral component on several different series of Yale and Hyster brand 3,000 to 4,000-lb capacity sit-down counterbalance trucks. It is also being installed on a series of three-wheel stand trucks. All platforms use independent in-line drive unit motors for maneuverability and are variations of 36V and 48V trucks. The new brakes incorporate a manual override that allows the truck to be towed with no need for additional tools or power sources.

Yale Lift Trucks

www.yale.com

Warner Electric

www.warnernet.com

::Design World::

Filed Under: Brakes • clutches, Material handling • converting, MECHANICAL POWER TRANSMISSION

Tell Us What You Think!