By Cliff Ortmeyer, Global Head of Technical Marketing, Newark

Those working in industrial automation today see the Industrial Internet of Things (IIoT) as a way to create a cohesive system of devices and applications. IIoT enhances the ability to share data seamlessly across machines and sites, optimize production, and find new cost-saving opportunities.

But many IIoT seekers quickly discover that their traditional operational technology (OT) architectures can’t be scaled, are priced prohibitively, and demand complex configuration and support. To make IIoT work, it should be built from the edge to the cloud, requiring a more distributed architecture that provides field-to-cloud connectivity for sensors and actuators, as well as the input/output (I/O) systems and controllers linked to them.

Traditionally, industrial automation architectures have addressed data processing in a hierarchy, as with the classic Purdue model. This hierarchical approach provides clarity as to where data can originate, be stored, and be processed and delivered. But the problem with this approach is the amount of work it takes to design, physically connect, configure, digitally map, communicate, and then maintain field data points. Transporting and processing data in this hierarchy is quite difficult because so many layers of equipment are required to connect devices and applications.

Spanning edge, fog, and cloud

The hierarchical approach was necessary when computing capability, network bandwidth, and security features were much less available. Each step up of the hierarchy from a basic hardwired sensor to the cloud was required to access greater computing and networking resources.

Today, the relationship has changed because sensors and other edge devices are farther along in terms of processing and communication capabilities. The architecture can now become flatter and more distributed, with a low-level device capable of sending data directly to its destination.

This network edge of low-level devices is still a critical source of data, and the cloud is still a valuable resource for heavyweight computing. However, the resources in between are becoming a blend of data-generating devices and data-processing infrastructures. This fuzzy middle ground earns the name fog because it’s like a widespread, pervasive, and middleweight cloud.

The goal is to balance computing and networking demands between the edge and higher-level systems. Edge computing offloads central processing, preserves data fidelity, improves local responsiveness and security, and increases data transfer efficiency to the cloud. But this new kind of edge-to-cloud architecture requires new options at the edge for acquiring, securing, storing, and processing field data.

It starts with a smarter approach to distributed I/O. Traditional architectures require enormous effort to design, connect, configure, digitally map, communicate, and then maintain I/O points for the field data. Adding even one point at a later date may require revisiting all of these steps.

Instead, industrial automation designers should bypass the layers between the real world and intermediate or top-level analytics systems. With enough computing power, all the necessary software for enabling communications can be embedded directly in an I/O device. Instead of requiring a controller to configure, poll, and communicate I/O data to higher levels, I/O devices can now transmit information on their own. This approach is called smart remote I/O or sometimes edge I/O.

Edge I/O takes advantage of these technologies and combines them with standard IT protocols like TLS (transport layer security) encryption, VPN (virtual private networking) for secure remote connection, and DHCP (dynamic host configuration protocol) for automatic addressing. Rather than requiring layers of supporting middleware, edge I/O devices are first-class participants in distributed systems.

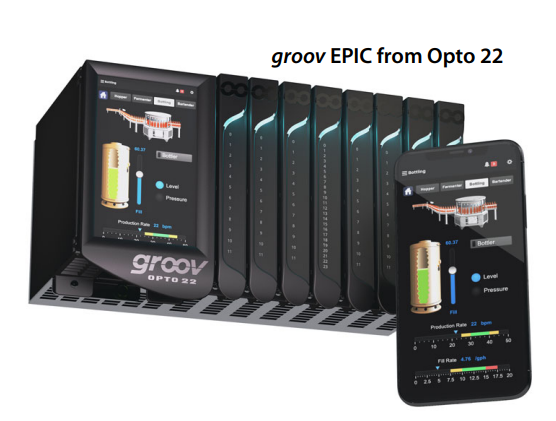

Next come edge controllers to tie it all together. Traditional industrial controllers are limited in scope and require intermediary systems to connect process data to the rest of the organization. Like edge I/O, modern edge programmable industrial controllers (EPICs), first introduced to the industrial automation market by Opto 22, leverage new technologies to assimilate more automation functions than previous generations could.

With industrially hardened components, secure networking, multi-language programming, and multi-core processing, edge controllers, like Opto 22’s groov EPIC, can deliver traditional real-time I/O control while also hosting communications, visualization, and even database servers. In IIoT applications, edge controllers can use this flexibility to communicate with an array of data producers, transform their data in meaningful ways, and deliver it securely to data consumers.

New architecture options

So what new architectural possibilities are available to designers using modern edge I/O and edge controllers? With edge devices making local data available to computing resources at the edge and at higher organizational levels, the logical hierarchy can be flattened even as the geographical distribution is expanded.

Where field signals are distributed over large geographic areas or multiple sites, edge devices can transmit data to networked applications and databases, improving the efficiency and security of local infrastructure or replacing high-maintenance middleware such as Windows PCs. The combination of smart hardware and software closes the gap between OT and IT systems, creating a unified data network that is scalable and centrally managed.

Edge I/O can also help integrate legacy devices. It can form a basic data processing fabric for existing equipment I/O in brownfield sites, and work in combination with more powerful edge controllers and IoT gateways. This approach improves security and connectivity without interfering with existing control systems.

Engineers can also design simple, flat, data processing networks using only edge I/O devices (without controllers or gateways), expanding as needed to monitor additional field signals. A distributed I/O system like this can process and report data directly to cloud-based supervisory systems, predictive maintenance databases, or MQTT brokers.

Edge devices with embedded MQTT clients can publish field data directly to a shared MQTT broker/server or redundant MQTT server group located anywhere the network reaches: on premises, in the cloud, or as part of regional fog computing resources. The broker can then manage subscribers to that data—any number of interested network clients across the organization, including control systems, web services, and other edge devices.

This new architecture makes seamless connectivity a reality as well, thanks to technologies that make ubiquitous data exchange possible. New hardware and software products enable interconnectivity among physical locations in the field, at the local control room, in the front office, across geographic regions, and up to global data centers.

Distributed edge I/O, edge controllers, and associated networking technologies support data transfer through the edge, fog, and cloud portions of an industrial architecture. Using this approach, designers can erase the former boundaries between IT and OT domains and get the data you need to optimize operations.

Final thoughts

The key challenges automation designers experience with IIOT are complexity, security, and high costs. Getting data from the edge of the network—from the sensors and actuators in factories, commercial buildings, and remote sites—to the databases and people who need to use that data can be daunting.

A new generation of distributed I/O technologies and control now gives them new possibilities for a connected IIoT-based infrastructure that can share data seamlessly across machines and sites to improve automation capabilities while cutting costs.

Newark

www.newark.com

Filed Under: IoT • IIoT • Internet of things • Industry 4.0