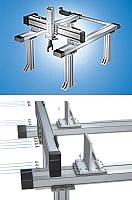

Charlotte, NC ‚– Rexroth has introduced an innovative approach to Cartesian Motion Systems that provides building-block style modular design of material handling, pick-and-place, palletizing, inspection, and related applications. Called camoLINE (camo=Cartesian Motion), the system includes electromechanical and pneumatic axes, bolt-together connection technology, and aluminum structural framing, which allows engineers to create the best fit for their applications.

The system includes pneumatic, ball screw and belt-drive actuators that offer high positioning accuracy or fast travel speeds according to system demands. Customers can also choose among servomotors, side drives with timing belts, or planetary gears to complement a variety of design requirements. The various drive technologies available with a single handling system make camoLINE an ideal candidate for applications in the assembly and handling, automotive, electronics and semiconductor, food and packaging, medical engineering, pharmaceutical and machine tool industries.

As a result of its build-block design, the camoLINE Cartesian Motion System provides complete flexibility, as users can locate holes as needed, work within broad configuration parameters, select from three types of actuators, and change the configuration quickly and easily. The system‚’s simple bolt-together connection streamlines assembly while offering all of the benefits of t-slotted aluminum framing. Likewise, brackets and cable management are standardized, which further simplifies design and construction tasks. Altogether, camoLINE shortens the design cycle, cuts assembly and installation time, and also provides an easy, online configuration tool that saves considerable time for system integrators and other frequent designers of multi-axis systems.

::Design World::

Filed Under: LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!