When Lifline, a company specializing in portable fall arresting systems for all kinds of uses, began to have issues in some systems with the wheels, engineers worked with Caster Concepts to develop a custom-designed wheel.

Rugged and fail-proof wheels are critical because if a component fails it could be the difference between life and death. Lifline had originally used a standard 8 in. wheel and pneumatic tires on some of its larger equipment. But the company found that a wheel of that size and strength, while sufficient to arrest someone’s fall, did not provide the “over-protection” that Lifline insists on in its systems.

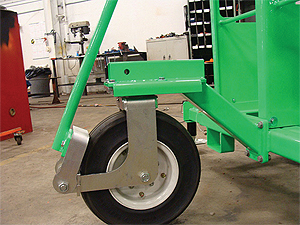

Caster Concepts worked with Lifline to develop a custom 16-in. wheel with a solid rubber tire that doubles as the steering wheel for positioning the fall arresting system. The new wheel assembly beefed up Lifline’s fall arresting equipment, making it more than sufficient to support the weight that occurs during a fall. Because of the wheel’s larger size, the fall arresting system is also easier to maneuver.

Caster Concepts

www.casterconcepts.com

Filed Under: Assembly, INDUSTRIAL SAFETY SYSTEMS

Tell Us What You Think!