Dorner’s FlexMove Helix Conveyors are manufactured to meet customer’s needs with build to order inclines and declines, which provide tight spirals in a small footprint for greater flexibility in layout for applications such as accumulation, buffering, cooling product and more. Additionally, Helix CAD models are now available for download in Dorner’s D-Tools, Dorner’s online conveyor…

Dorner celebrates its 55th year in conveyor business

Dorner, producer of low profile conveyer systems for industries including automation, food, manufacturing, packaging and many others, this month is celebrating its 55th anniversary in business. From its humble beginnings as a little tool and die shop, Dorner has evolved through the years to become one of the most recognized global brands. In 2016, Dorner…

Larger 303SS Air Conveyor converts standard pipe to convey in corrosive environments

EXAIR’s new Type 303 Stainless Steel 3 NPT Threaded Line Vac Air Operated Conveyors convert ordinary pipe into a powerful conveying system for parts, scrap, trim and other bulk materials. This chemical and corrosion resistant Line Vac operates seamlessly at higher temperatures providing a long-lasting and low maintenance solution ideal for food, chemical, pharmaceutical and…

XTS offers hygienic design for compact, flexible motion control with optimal cleanability

XTS Hygienic, the stainless steel version of the eXtended Transport System from Beckhoff, is now available in the U.S. The IP69K-rated linear transport solution opens up a wide spectrum of new applications, primarily in food and pharmaceutical industries and for processing and filling liquids. With optimal cleanability, high chemical resistance and no hidden corners, edges…

EXAIR offers large selection of air operated conveyors with no moving parts

EXAIR offers a large selection of Line Vac conveyors that are ideal for moving large volumes of material over long distances. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other, with instantaneous response. The material flow rate is easily controlled…

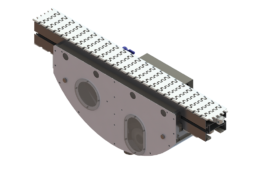

Build your own Edge Roller Technology (ERT250) conveyor online with Dorner’s D-Tools Conveyor Configurator

CAD models of Dorner’s new Edge Roller Technology (ERT250) conveyor are now available in D-Tools, Dorner’s online conveyor configurator. Downloading CAD models on D-Tools gives product engineers, plant managers and others the ability to easily design an ERT250 conveyor to fit their exact application in a matter of minutes. D-Tools, which includes 2D and 3D…

Wear resistant pneumatic conveyor provides high throughput

EXAIR’s new 2-1/2 NPT Heavy Duty Threaded Line Vac is a powerful in-line conveyor that transports high volumes of material through ordinary pipe. Designed for rugged, industrial applications, it has a hardened alloy construction that helps prevent premature wear when transporting abrasive or heavy materials like shot blast, tumbling media or metal fittings. These units…

Ultimation Industries joins Rolling On Interroll’s partnership network

Ultimation Industries announced today that the company was selected as the newest member of Rolling On Interroll (ROI), a unique partnership with global material handler Interroll. Ultimation is a woman-owned leader in the conveyor technology and automation industry and has been designing, manufacturing and installing machinery and equipment, automation devices, tire and wheel processing lines…

Edge Roller Technology (ERT 250) conveyor highlights Dorner’s PACK EXPO Connects 2020 Virtual Showroom

Dorner’s new Edge Roller Technology (ERT 250) conveyor highlights an exciting week of virtual activity at PACK EXPO Connects, Nov. 9-13, 2020. Dorner’s virtual showroom can be visited at: https://pe.show/176. The ERT250 is a pallet handling conveyor capable of zoning for accumulation and automation assembly applications. As implied by its name, the ERT250 uses rollers…

Dorner Latin America now building 2200 Series Precision Move Pallet System Conveyors in Mexico

Dorner Latin America continues to grow their capacity by adding the 2200 Series Precision Move Pallet System Conveyor as its fourth major platform to be assembled at their facility in Guadalajara, Mexico. The 2200 Series Precision Move Pallet System Conveyor is designed to increase efficiency and reduce downtime in assembly automation processes for their Latin…

Hold back or pace products with clamping module for FlexMove conveyors

Dorner is now offering a Clamping Module on its FlexMove conveyor system that gives users the ability to hold back or pace products for accumulating applications. The Clamping Module is ideal for totes, boxes, bottles and square, round and rectangular containers. As products pass through the Clamping Module, pre-programmed photo sensors trigger a pneumatic-clamping actuator…

Edge Roller Technology conveyor receives Class 4 cleanroom certification

Dorner’s new Edge Roller Technology (ERT 250) conveyor has received certification for use in ISO Standard 14644-1 Class 4 rated cleanrooms. This means Dorner’s ERT250 will conform and not contribute to the contamination of cleanrooms to those standards. Cleanrooms and other controlled environments provide management of airborne particulate contamination to appropriate levels for accomplishing contamination-sensitive…

New Edge Roller Technology (ERT 250) Conveyor from Dorner

Need a pallet handling conveyor capable of zoning and packing for accumulation and automation assembly applications? As implied by its name, the ERT 250 uses rollers to move pallet conveyors smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor’s open design eliminates concerns of small parts or screws dropping into rollers…

Dorner’s responsiveness helps deliver 2200 Series conveyor for manufacturing of N95 respirators

As the COVID-19 pandemic continues causing major disruptions throughout the packaging industry on levels never seen before, Dorner is meeting these challenges head-on by leveraging its expertise and expediting its conveyor systems to critical applications. Husco is one of those applications. Waukesha, Wisconsin-based Husco, a privately-held company specializing in high performance hydraulic and electro-mechanical components,…

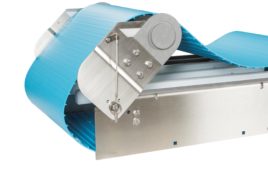

Dry and wet cleaning modules for continuous cleansing on FlexMove conveyors

Dorner is offering two cleaning modules for both dry and wet applications on its popular selling FlexMove system that allows continuous cleaning while the conveyors are operating. Designed for FlexMove conveyors, the Dry Cleaning Module provides continuous cleaning of conveyor chain for applications involving powder, dust and other dry contaminates, whereas the Wet Cleaning Module,…

Visit Dorner Virtual Interpack Booth 2020 from the comfort and safety of your office or home

Although Interpack 2020 has been postponed to early next year, people can still visit Dorner’s booth and see all the excitement and conveyor systems on display. Dorner has launched its new Virtual Interpack Booth 2020, an interactive platform highlighting the 2200 Series, FlexMove and the AquaGard 7350 V2 Series – the three conveyor systems that…

Dorner continues its European expansion by building 2200 Series LPZ Conveyors from its German manufacturing facility

Dorner Europe is expanding its presence throughout the region by adding the 2200 Series LPZ (Low Profile Z-Frame) Conveyor to its lineup of conveyor platforms being manufactured from its Jülich, Germany, location. Dorner (http://www.dornerconveyors.com) is an industry leader in the design, application, manufacturing and integration of precision industrial and sanitary conveyor systems. The advantage of…

Dorner’s AquaGard and AquaPruf Conveyors Earn BISSC Certification for their High Sanitary and Safety Attributes

Dorner’s AquaGard and AquaPruf sanitary conveyor platforms have again earned the coveted Baking Industry Sanitation Standards Committee (BISSC) certification for conveyors outlined in ANSI/ASB/Z50.2-2015. BISSC certification is recognized as the definitive sanitation and safety standards for equipment used in the baking industry. BISSC is a not-for-profit corporation that, working with the American Society of Baking…

Dorner’s Engineered Solutions Group injects automation and ingenuity into conveyor systems for complex applications

When a customer needed to upgrade their existing food processing line to merge two lanes of frozen pizzas into a single lane, Dorner’s Engineered Solutions Group designed the perfect custom solution. Dorner’s Engineered Solutions Group (ESG) gives extra attention to building conveyor systems with unique dimensions and performance characteristics above and beyond Dorner’s regular conveyor…

Dorner Latin America now building 2200 Series modular belt conveyors in Mexico

Dorner’s facility in Guadalajara, Mexico, (Dorner Latin America), is already expanding its manufacturing capabilities by now building its 2200 Series Modular Belt Conveyor for customers throughout Latin America. Dorner is an industry leader in the design, application, manufacturing and integration of precision industrial and sanitary conveyor systems. Dorner Latin America is staffed with experienced employees…

Dorner’s FlexMove conveyor platform represents a merger between two existing product lines

Dorner has consolidated two existing product lines and unified them into a single platform, which is now called FlexMove. While the FlexMove name isn’t new to Dorner, it now incorporates the features and strengths of the former SmartFlex conveyor line. The FlexMove flexible chain conveyor brings the best engineering and performance standards in flexible conveying…

SuperTrak brings batch size one to the metal industry

The metal industry is not immune to the global trend away from bulk annual orders toward small-batch customer orders with short lead times. To handle this type of individualized production in batch sizes as small as one, manufacturing systems must become much more flexible. B&R’s booth at EMO (Hall 9, Booth F50) will showcase track-based…

New components for conveyors

New Elesa conveyor components allow the creation of support structures for production lines in diverse industrial markets, such as bottling, packaging and material handling. Elesa now offers new roller sides and central guides, linear guide rails, also with shaped profile and a series of accessories. These have been added to the already available range of…

Power four curves on a single motor for Sanitary Platform: AquaGard 7350 V2 conveyor

Dorner’s AquaGard 7350 V2 Curve Conveyor chain features a center bearing to eliminate friction, carry a heavier load and allow four curves to be driven by a single motor. This unique design improves productivity, along with saving valuable floor space as the conveyor can make tight turns around existing machinery and equipment without being hindered…

Build your own AquaGard 7350 V2 Series sanitary conveyor online

Two models from Dorner’s newly redesigned AquaGard 7350 V2 Series are now available in D-Tools, Dorner’s online conveyor configurator. The AquaGard 7350 V2’s Positive Drive and LPZ (Flat and Cleated belt) models on D-Tools give project engineers, plant managers and others the ability to easily design an AquaGard conveyor to fit their exact application in…