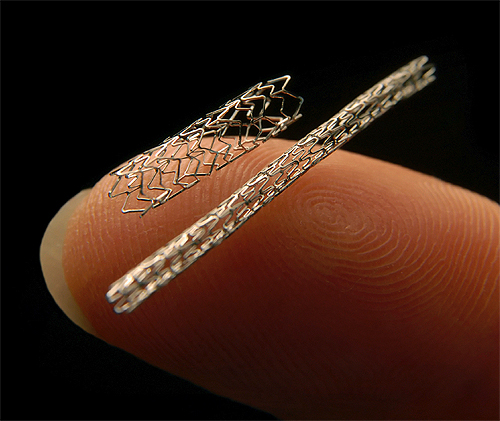

A new series of rotary stages from Aerotech features integral pneumatic collet chucks for automated material handling. The CCS series (U.S. patent pending) supports precision laser machining and micromachining of tubular products in plastics, metals and many other materials. It is particularly suited for cylindrical tube laser machining of medical products including stents and fine tubes.

New CCS rotary stages from Aerotech feature integral pneumatic collet chucks for automated material handling.

The unique collet chuck design allows workpiece advance without manual realignment to compensate for axial tube motion during clamp/unclamp cycles. Axial motion is significantly reduced, eliminating the need for part re-registration after tube advancement in applications requiring high precision gripping of the material.

Precision cylindrical tube laser machining of cardiac stents is a key application for new CCS rotary stages from Aerotech.

Using readily available collets, the CCS stages support tube diameters from 0.1 mm to 27 mm. A clear aperture assures efficient product feed-through. Housings are designed to accept wet-cutting accessories, and the stages tolerate inevitable moderate leakage of cutting fluid into the aperture.

Direct drive motor technology provides quicker acceleration and higher maximum speeds than gear or belt-driven mechanisms. With no brushes to replace or gear trains to maintain, the stages are optimized for 24/7 production environments.

Aerotech

www.aerotech.com

Filed Under: Stages • gantries, Medical-device manufacture, Material handling • converting, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!