The CD66 (Capacitor Discharge) Welder is designed for the convenience and comfort of the operator. With a stud capacity of up to 1/4″ steel and stainless steel, the unit is ideal for use in light industrial applications. Its portability on the job – enhanced by its adjustable shoulder strap – makes the CD66 a smart choice for insulation applications as well.

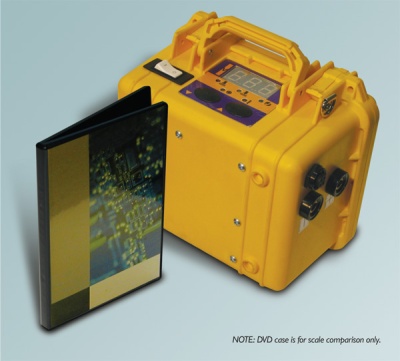

The CD66 measures 10 5/8″ x 9 11/16″ x 6 7/8″ (270 mm x 246 mm x 174 mm) and is lightweight at 10.5 lbs (4.76 kg) – the lightest unit available. Its tough, corrosion-proof plastic case is made from an ultra-high-impact co-polymer that provides extra insulation and resists rusting and denting in even the most demanding work environments. The demand fan and thermal shut-down protection also prevent possible damage to the unit.

The CD66 allows you to auto-select the type of welding on the spot, by supporting both gap and contact welding. The CD66 ensures safe operations for all users. A microprocessor conducts continuous system checks for component fault and controls unit shut-down. Dual weld SCRs provide maximum weld current restriction safety. Operator lights clearly indicate status, and the included manual simplifies error code look-up.

FEATURES AND BENEFITS

* The most compact and lightweight welding unit available in the industry

* Designed to support both gap and contact welding methods

* Rugged construction stands up to even the roughest treatment and harshest environments

* Highly flexible design can be used in a wide range of industrial and insulation applications

* Rapid operation delivers an incredible 24 continuous welds per minute

* Innovative safety features protect operators like no other unit can

* Ground Fault Interruption (GFI) protection – an industry first

::Design World::

Filed Under: FASTENING • JOINING • locks • latches • pins

Tell Us What You Think!