California State University (CSU), Chico is one of the oldest post-secondary institutions in California and among the most highly ranked public universities in the West. The university offers a very hands-on, practical learning environment, which attracts a large number of students. The goal of this type of learning is to make the students better prepared for real-life employment. On average CSUC welcomes 80 new students each year to its Mechanical Engineering program and as part of their practical training, students are currently working on projects with industrial hardware donated by B&R Industrial Automation.

In 2007 Nick Repanich, Adjunct Research Professor at the Department of Mechanical Engineering, Mechatronic Engineering, & Manufacturing Technology at CSUC was looking for a unique concept of having one programming environment to control many devices, and the ability to chose a programming language that would suit various class levels, including ladder logic. “Before we had all this actual industrial hardware from B&R, like controllers, pneumatics, steppers, we had a design project that used various items, like straws, mousetraps, doweling, hot glue, paperclips etc. to solve some problems”, says Nick Repanich.

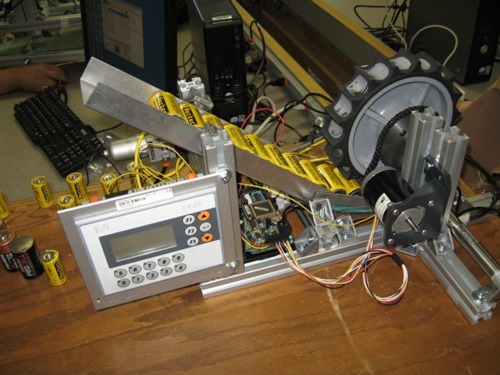

Each semester the students at CSU Chico have to build different machines with automated solutions. In each project they use the B&R Power Panel (PP35) as the main controller. The PP35 is designed for use as a controller and operator panel. Additional peripheral devices can be connected via the standard integrated B&R CAN interface. The Mechanical Engineering students control pneumatic actuators, read sensors, control stepper motors and in one particular project read the analog voltage of a battery to determine its condition. “We are now able to teach critical technologies that all engineers should know”, explains Repanich.

Machine that tests C-cells and D-cell batteries and sorts them into good and bad bins controlled by a B&R Power Panel (PP35)

Chico State also is the first University to offer the Mechatronic Engineering degree 15+ years ago. “What we really like about CSUC is their focused practical teaching with real projects. B&R is working close with lots of universities and we want to make sure, that students learn on the latest hardware to be qualified for their future jobs”, says Robert Muehlfellner, Director Automation Technology at B&R Industrial Automation. “A combination of theoretical and practical experience is very important. At B&R we also have a large number of seminars, workshops etc. to continuously train and qualify our employees as well as a 4 month long project-oriented ‘training camp’ for all new employees.”

Automated screw driving machine that put a custom machined faceplate onto a lighted receiver hitch, controlled by a B&R Power Panel (PP35)

The setup for the B&R PP35 is pretty fast. The students can take the hardware directly out of the box, wire it up and control simple input and outputs within 2 hours, with some help from the instructor, and only the help tools from B&R. Apart from these projects, students take the same ABET required classes as any other university. “At the end of their Bachelor’s degree, our students are sought after as ready-to-work and actually do something due to the large number of student projects and the type of hands-on education they get there”, says Repanich.

::Design World::

Filed Under: Student programs, Power supplies, Motion control • motor controls, Mechatronics

Tell Us What You Think!