Early stage design decisions have big impacts. Early stage design studies guide decisions about layout, material choice, make-or-buy, initial definition of subsystems, production methods and many others. These choices form the framework for the rest of the project, and so have a direct impact on costs, successes and problems later on. Software tools that support better early stage design decisions offer big ROI potential.

New Tools

It’s not unusual to find detail design tools and spreadsheets at the core of the toolsets used in early stage design. But trends including growth of systems engineering and new simulation and analysis capabilities are driving more capability into the hands of early stage developers. In this article, I’ll characterize early stage work, and then select a few examples of engineering software tools that are addressing these needs.

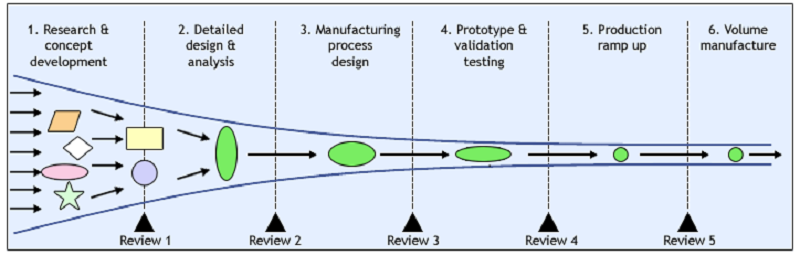

Image credit: Cambashi

The broad principle is the same across the spectrum, from high-cost one-offs such as buildings, ships, and process plants, all the way to low-cost, high-volume products such as disposable razors and even toothpicks (wood or plastic? Individually wrapped or multipacks? 50mm or 60mm?). Early decisions, viewed in the context of the project, tend to be big decisions. These decisions establish the framework for future work, and are expensive to change. Yet in most cases, a relatively low share of the total project development resource is allocated to making these decisions.

This is why, when viewed from the stratosphere, product development still tends to look like a one-way process, in which multiple design studies are used to guide choices between alternatives, one of which is chosen for development (fig. 1 shows a volume manufacturing example).

It’s not a one-way street

Move in from the stratosphere, and of course the process is far from one-way. Agile methods enable development engineers across the whole lifecycle to try relevant ideas in every sprint. Also, systems engineering is helping multi-technology product development teams divide tasks across mechanical, electrical, fluids, and software. This partitioning enables concurrent work on multiple subsystems.

So what is different about early stage work? Of course there is uncertainty. Also, setting up the context and environment needed for the new design can be time consuming and can feel like overhead. The definition available for all the current design ideas is very limited, so it can be difficult to evaluate those ideas. Some ideas may turn out to be requirements (connected to the Internet, energy consumption less than x, etc.), and the early stage designer has to seek out all the implications.

The ability to perform analysis and simulation based on limited inputs used to be confined to big-ticket projects and special cases where someone built a useful spreadsheet. Now there are tools relevant to every product development team. Some help convert broad brush into more detail. Some enable more evaluation of broad-brush definitions.

Image credit: Cambashi

Tools, what tools?

Component and material suppliers have always invested sales effort in order to get involved in early stage design. If they can get their products selected at the early design stage they will almost certainly achieve better margins than will be needed to win a sales battle later. So these companies find ways to make it easier for design engineers to select their products, not competitor products, early in the project. From glossy brochures and well presented datasheets the approach has moved on to digital component libraries (saves drawing and modeling time); extensive metadata (saves documentation time); and configurators (instant identification and selection of all the ‘support’ parts needed to use a chosen component). Product and manufacturing process simulation has always been important to material manufacturers, so, for example, simulation technology vendors seek support from material providers to handle cases such as simulation of fiber-filled materials in injection molding.

But this is only one source of tools to use. There are many types of tools. Some apply across a broad range of product types; some are more industry or technology focused. To give a taste of what’s available, I’ve listed eight tools types with an example of each. These range from engineering calculations to sketch capabilities to topology optimization. Support for early stage design decisions is at least part of the purpose, and sometimes the dominant part of the purpose of these tools.

- Engineering calculations. (PTC Mathcad)

- Construction project definition. (Autodesk Infraworks 360)

- Sketch. (Siemens Catchbook)

- Materials. (Granta MI)

- Systems Engineering. (Siemens LMS Imagine.Lab Embedded Software Designer)

- Systems Configuration. (Vention Industrial Design)

- Topology Optimization. (Dassault Systemes)

- Generative Design. (Autodesk)

Is this a trend?

Several trends in the marketplace are converging to help better serve early stage design. It would be hard to say that market demand for early stage design tools was the factor driving these trends. Key among the relevant trends are:

- Democratization. Software vendors always seek new users. Early stage designers include senior people with a range of responsibilities, so will never be full time users of any system. Easy, discoverable, intuitive UIs make tools accessible to these people.

- New simulation/analysis. The fact that simulation and analysis originally was something that happened downstream has been a barrier. The combination of easier modeling and integrated analysis allows early stage designers to run simulations earlier in the project, trying and testing ideas, using agile methods to refine requirements and then try new ideas.

- Growth of systems engineering. 50 years ago, SE happened in most aerospace projects and many military and some automotive projects. It developed a reputation for being a documentation heavy, bureaucratic approach. Even 20 years ago, tools were largely requirements management, except in software development, where structured analysis and modeling was well established, and tools could be linked to code generation and test. But now, systems engineering tools are relevant for multi-technology products across most industries, and can be key to managing complexity.

Where next?

Strong take up of tools in early stage design will make it hard to recruit design engineers into an environment without these tools. These hard-to-recruit design engineers will have become used to projects in which early stage decisions are almost always good decisions. For them, an environment where it’s not unusual to discover big problems late in a project will feel like a backwards career move.

The role of component and material suppliers also looks set to grow. Design tools from suppliers, often low cost or even free, are growing in scope, for example, automatic generation of bid documents; or verification that selected components match fire regulations. Of course, designers have to accept that the best functions only work when applied to the parts of the design based on products from that supplier.

Another axis of growth is the product lifecycle – from first idea through to recycling. The IoT has the potential to drive a complete rethink about requirements gathering – design and development engineers will be connected to products in the field, so plans for the next version can be based on observation of in-service performance of the current version. But the central upstream opportunity is to drive out cost by helping companies be right the first time, every time in the big, early stage decisions – about products, materials, manufacturing processes, and, for smart connected products, the distribution of functions between the device and the connected systems. Simulation capabilities integrated with systems engineering will provide the capabilities; easy-to-use interfaces will make these capabilities accessible to the right people.

Disclosure: Autodesk, Dassault Systèmes, PTC and Siemens are Cambashi clients.

Filed Under: Rapid prototyping