Miniature pneumatics valve manufacturer Clippard Instruments Laboratory Inc. (www.clippard.com) has equipped its 10 mm miniature valves, which offer a working pressure of up to 110 psig/7.6 bar and a temperature rating of up to 122°F, with the same brand of quality and reliability offered in its other products.

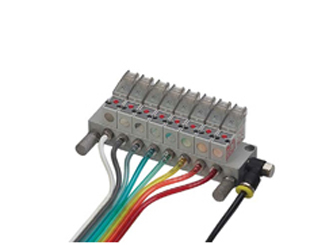

The two-way and three-way valves are available in both Normally Open and Normally Closed variants, and are perfect for space restricted areas that require pneumatic controls. Featuring a lightweight engineered glass filled nylon body, the series also comes with copper, stainless steel and Buna-N or Fluorocarbon Elastomer.

In addition, the RoHS compliant valves offer exceptional reliability and longer service life. Its coil is made of copper wire and is isolated according to class “F” standard.

Weighing just 0.4 ounces, the 10 mm valve features connections and circuitry that are protected from corrosion. Its highly visible manual override offers valve actuation even without power, while its glass filled nylon housing are highly durable and corrosion-resistant. Multiple connectors include wire leads, snap-in plugs and custom plugs.

Clippard’s 10 mm valve also has the capability to detach the connector and the coil from the valve body. This is useful when exchanging voltages or connector types, or when positioning the coil by 180 degrees.

The company has also fitted the valves with LED for confirmation of operation and diodes for current spike suppression.

To help users identify the valve, the company has color coded the top plate — silver plated valves are the Normally Closed version, while black plated valves are the Normally Open.

Filed Under: Cables + cable management, Connectors (electrical) • crimp technologies, Pneumatic Tips