In some semiconductor applications, it is required to test components in hot air to meet certain standards. The CLWT-115 research quality closed-loop wind tunnel provides an accurate and convenient system for thermally characterizing PCBs, heat sinks and components at controlled temperatures from ambient to 85°C (185°F).

The wind tunnel produces air flows up to 5 m/s (1,000 ft/min). Using optional orifice plates it can generate flows up to 50 m/s (10,000 ft/min). The instrument’s clear Lexan test section provides a continuous view of the test specimens, as well as flow visualization studies, using smoke or vapor.

Unlike open loop wind tunnels, the CLWT-115 recirculates internal air. This allows the system heater to quickly warm the air to a specific temperature. The precise controls and temperature range of the wind tunnel allows its use for testing heat sink performance and for calibrating air and temperature sensors.

The wind tunnel provides a generous test section measuring 77.6 cm x 26 cm x 11.6 cm (30.5 in. x 10.2 in. x 4.55 in.). This chamber can be accessed from the top or sides for mounting and repositioning boards, components and sensors. Internal rail guides provide an easy system to install test specimens of different sizes, such as PCBs and heat sinks. Six instrument ports in the sidewalls of the test section are for temperature and velocity sensors such as thermocouples, Pitot tubes and hotwire anemometers.

A complete CLWT-155 wind tunnel fits on most lab benches and is powered from standard AC outlets. Its footprint is smaller than traditional, closed loop wind tunnels or environmental test chambers.

Advanced Thermal Solutions

www.qats.com

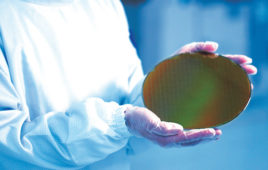

Filed Under: Semiconductor manufacture

Tell Us What You Think!