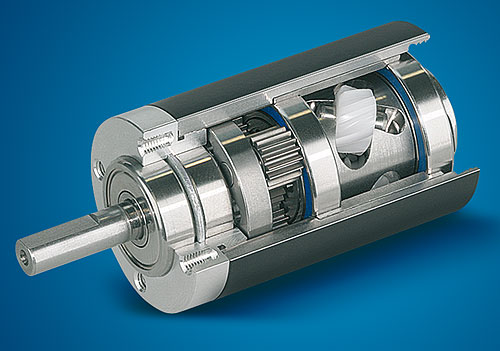

The low noise coaxial-drive (Koaxdrive) KD 32 planetary gearhead from maxon motor is setting new standards in operating noise and torque levels. Measuring 32 mm in diameter and with a torque of 6.5 Nm, it is ideal for use in noise-sensitive, highly demanding applications.

The new Koaxdrive KD 32 combines the best of two proven gearing technologies, namely worm and planetary gearing. Special attention has been focused on the first gear stage, as this is where the greatest peripheral speeds occur and therefore noise. Our completely new, patent-protected design has enabled us to substantially reduce this noise. The worm-formed motor pinion drives the three offset planetary wheels interlocking with the internal gear which has straight cut teeth. The plastic planetary wheels are largely responsible for reducing noise levels.

All additional stages are set out as a completely ‚“normal‚†straight-cut planetary gearhead. This unique torque conversion makes operation very quiet – even with high loads.

With an outer diameter of only 32 mm and a coaxial arrangement on the drive and output shaft, the Koaxdrive is designed for compact applications. A number of efficiency levels with the same reduction ratio increases the wide variety of applications. In the 11:1 to 1091:1 range, many reduction ratios are available as standard. maxon motor also offers high reduction ratios in one stage. A new, innovative coupling element is assembled on the motor side so that the motor shaft is not subjected to axial load. Input speeds of up to 8,000 RPM can easily be reached.

maxon‚’s modular system enables the Koaxdrive KD 32 to be assembled with various maxon motors. These low-noise combinations are ideal for hand tools and instruments that are used principally on or near patients in the medical technology sector.

::Design World::

Filed Under: Gears • gearheads • speed reducers, Motion control • motor controls

Tell Us What You Think!